Multi-pulse conversion exhausting device of 8-cylinder straight-row diesel engine

A technology of exhaust device and pulse converter, applied in exhaust device, muffler device, mechanical equipment, etc., can solve problems such as mutual interference between exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

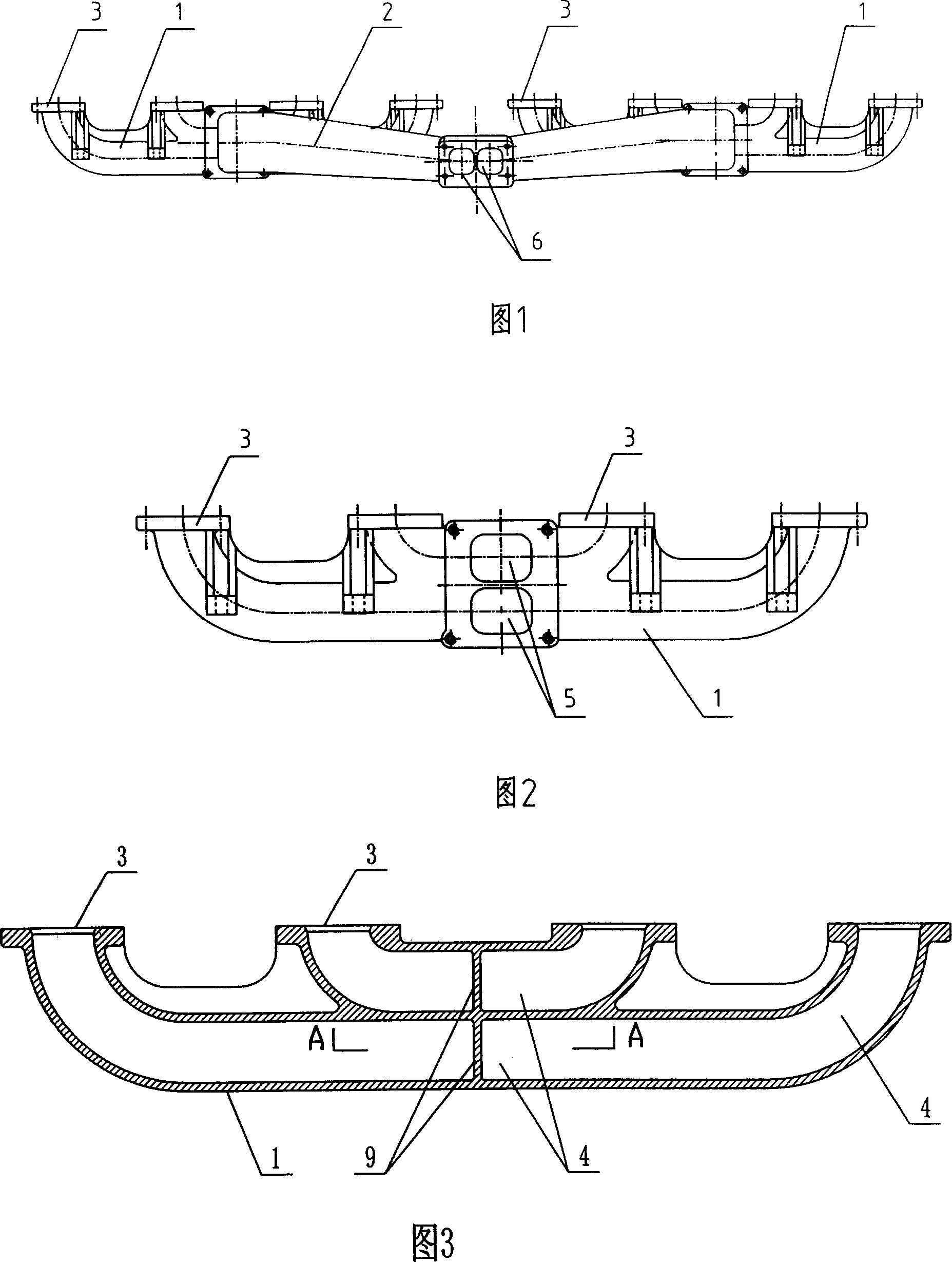

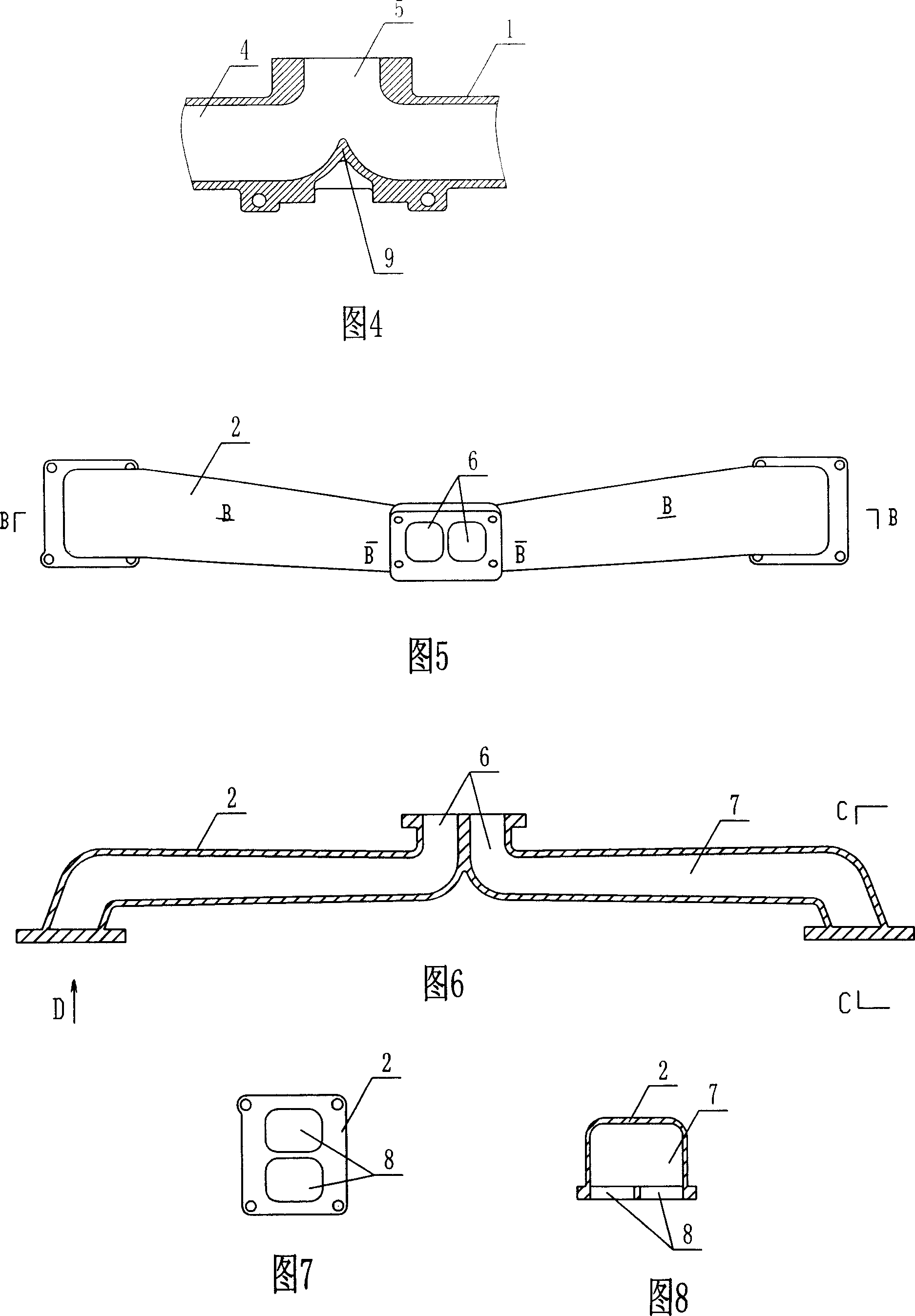

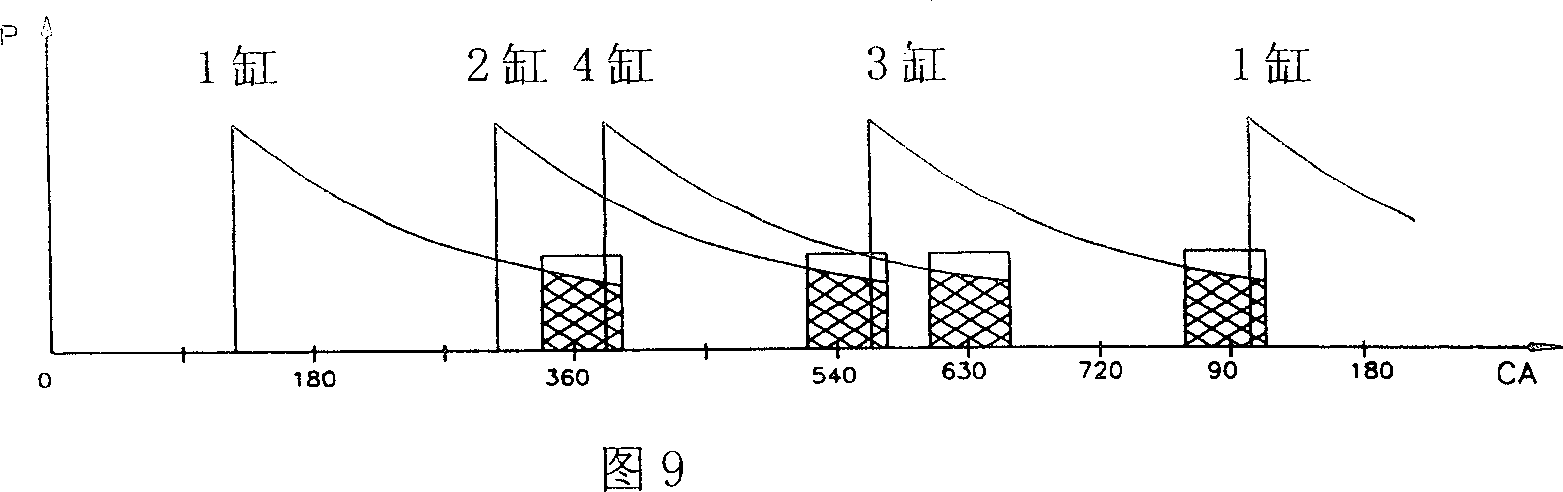

[0023] With reference to the accompanying drawings, the multi-pulse conversion exhaust device for an 8-cylinder in-line diesel engine includes an exhaust pipe 1 connected to the cylinders of the in-line diesel engine. The pipe 1 is divided into two sections with the same structure, the 1-2-3-4 cylinders of the in-line diesel engine share a section of exhaust pipe, and the 5-6-7-8 cylinders share a section of exhaust pipe. Each section of exhaust pipe 1 has four air inlets 3 and two air outlets 5, and each section of exhaust pipe 1 is provided with two flow channels 4 in parallel, wherein two adjacent air inlets 3 share one flow channel 4 and an air outlet 5, the two air inlets 3 on opposite sides share a flow channel 4 and an air outlet 5, that is, the four cylinders 1, 2, 3, and 4 share an exhaust pipe, 5, 6 , 7, 8 these four cylinders share an exhaust pipe. Cylinders 1-4, 2-3 each share a flow passage, and they are introduced into one of the air inlets of the pulse converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com