Moulding method for insulating part manufacture of high-voltage cable accessory and moulding mold

A high-voltage cable and molding method technology, which is applied to insulators, electrical components, circuits, etc., can solve the problem of not being able to take into account the molding of liquid and solid materials at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

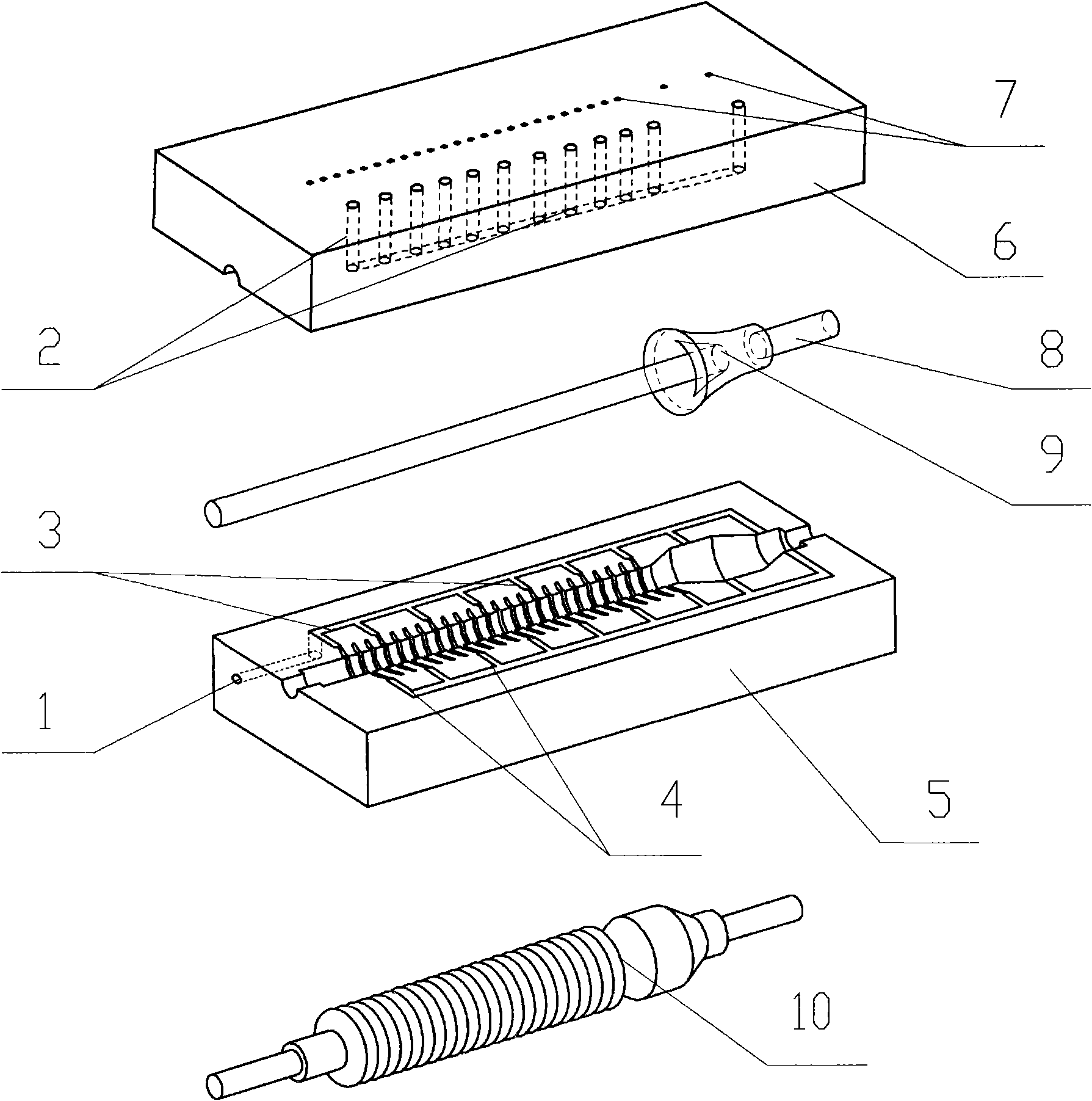

[0010] exist figure 1 Among them, the molding method for manufacturing the insulating part of the high-voltage cable accessory 10 uses the method of upper and lower mold clamping. This molding mold is composed of an upper mold 6, a lower mold 5 and a mold core 8. The inner groove is shaped like a high-voltage cable accessory. 10 The shape of the insulating part, there is a group of longitudinal ports 2 near the end of the upper mold 6, and there are a plurality of exhaust holes 7 on the longitudinal axis of the surface of the upper mold 6; there is a group of transverse holes 4 corresponding to the longitudinal ports 2 on the lower mold 5 , The transverse hole 4 communicates with the mold cavity, and the lower mold 5 also has a group of transverse holes 3 and a vertical and horizontal mouth 1 communicating with it, and the transverse hole 3 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com