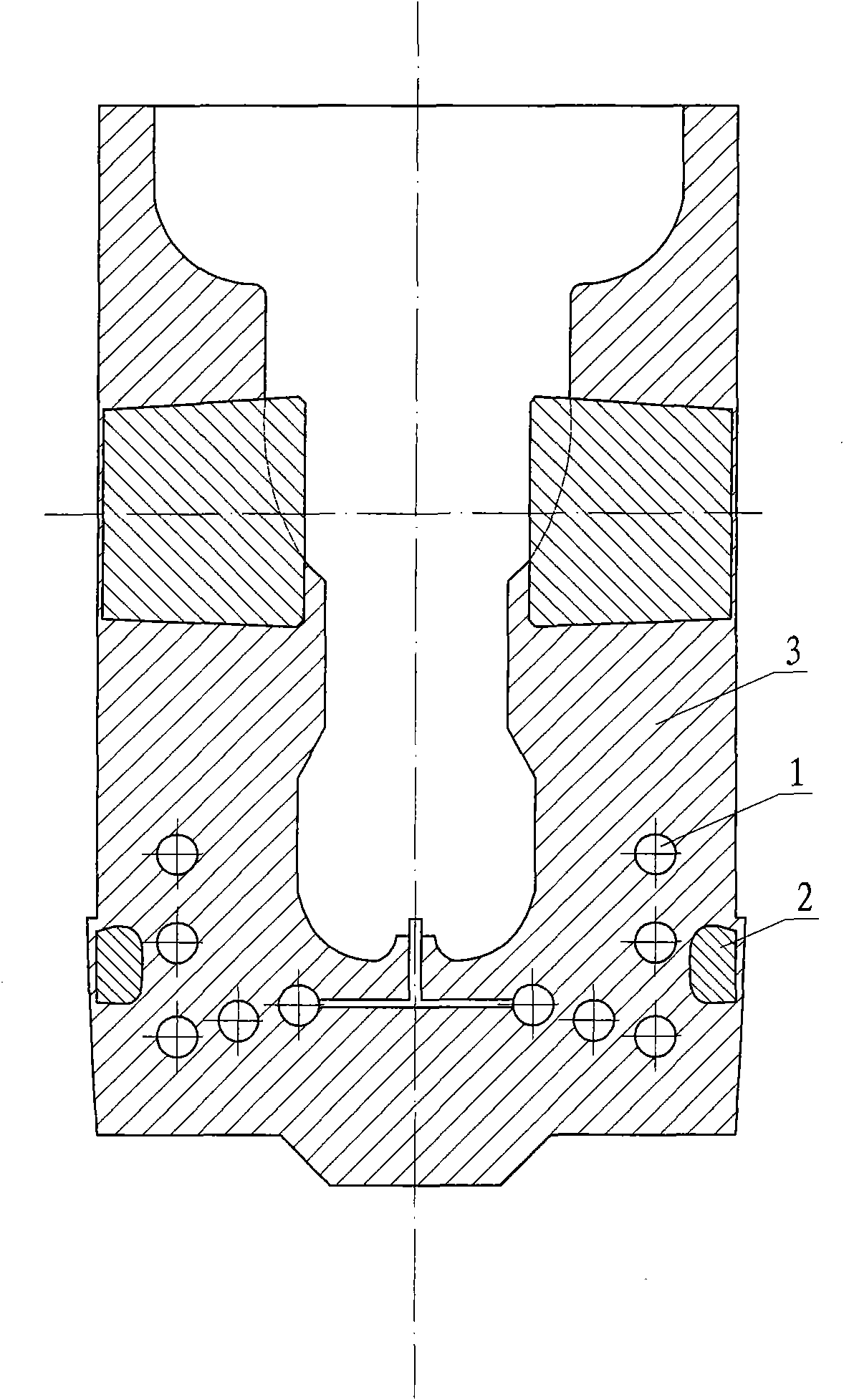

Method for casting aluminum piston with insert ring and cooling coil pipe

A technology for cooling coils and pistons, applied in the field of aluminum piston casting, can solve the problems of poor integration between the insert ring and the piston body, inaccurate positioning of the cooling coils, high manufacturing costs, etc. High utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation process of aluminum piston is as follows:

[0034] ①Preparation of aluminum alloy for ZL109 piston, its material is composed of the following components and weight percentages: Si: 11.5%; Mg: 0.8%; Cu: 0.5%; Ni: 1.0%; Fe: 0.1%; Ti: 0.01%; Mn : 0.01%; Zn: 0.01%; Cr: 0.001%; Pb: 0.001%; Sn: 0.001%; the rest is AL;

[0035] ②The prepared aluminum alloy is heated and melted in a melting furnace. After the aluminum alloy is completely melted into molten aluminum, the temperature of the molten aluminum is adjusted to 760°C, and a compound phosphorus salt modifier is used for modification treatment. The weight of the added weight is the weight of the smelted aluminum alloy 0.2% of the molten aluminum; lower the temperature of the molten aluminum to 740°C, and use an aluminum-titanium-boron refining agent for refining treatment, and the added weight is 0.10% of the weight of the smelted aluminum alloy; drop the temperature of the molten alumi...

Embodiment 2

[0044] ①Preparation of aluminum alloy for ZL109 piston, its material is composed of the following components and weight percentage: Si: 12.0%; Mg: 1.0%; Cu: 1.0%; Ni: 1.2%; Fe: 0.2%; Ti: 0.1%; Mn : 0.1%; Zn: 0.1%; Cr: 0.01%; Pb: 0.01%; Sn: 0.005%; the rest is AL;

[0045] ②The prepared aluminum alloy is heated and melted in a melting furnace. After the aluminum alloy is completely melted into molten aluminum, the temperature of the molten aluminum is adjusted to 770°C, and a compound phosphorus salt modifier is used for modification. The weight of the added weight is the weight of the smelted aluminum alloy. 0.3% of the molten aluminum; the temperature of the molten aluminum is lowered to 750°C, and the aluminum titanium boron refiner is used for refining treatment, and the weight added is 0.15% of the weight of the smelted aluminum alloy; the temperature of the molten aluminum is lowered to 730°C, and the refining agent is used for refining Refining treatment, the added weigh...

Embodiment 3

[0053] ①Preparation of aluminum alloy for ZL109 piston, its material is composed of the following components and weight percentages: Si: 13.0%; Mg: 1.3%; Cu: 1.5%; Ni: 1.5%; Fe: 0.4%; Ti: 0.2%; Mn : 0.2%; Zn: 0.2%; Cr: 0.05%; Pb: 0.05%; Sn: 0.01%; the rest is AL;

[0054] ②The prepared aluminum alloy is heated and melted in a melting furnace. After the aluminum alloy is completely melted into molten aluminum, the temperature of the molten aluminum is adjusted to 780°C, and a compound phosphorus salt modifier is used for modification. The weight of the added weight is the weight of the smelted aluminum alloy 0.4% of the molten aluminum; lower the temperature of the molten aluminum to 760°C, and use an aluminum-titanium-boron refining agent for refining treatment, and the added weight is 0.2% of the weight of the smelted aluminum alloy; drop the temperature of the molten aluminum to 740°C, and use a refining agent for refining Refining treatment, the added weight is 0.5% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com