Oil pump vehicle evacuation oil-gas separator

A separation device and vacuum pumping technology, which is applied in the direction of separation methods, liquid degassing, chemical instruments and methods, etc., can solve the problems of high investment cost, excessive gas, and small diameter of vacuum pumping pipelines, so as to improve the opening sensitivity and reduce the The effect of using cost and reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments:

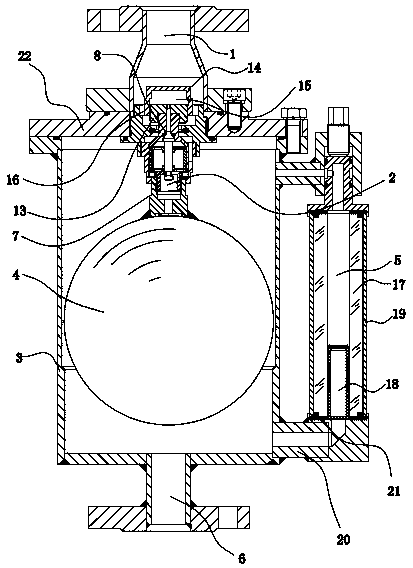

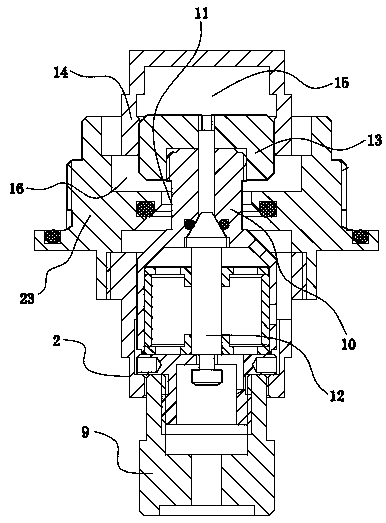

[0019] See attached figure 1 with 2 , An oil pump truck vacuum oil and gas separation device, comprising a casing 3, arranged at the bottom of the casing 3 for connecting with the main oil pump on the vacuum pipeline, the oil and gas inlet channel 6 arranged on the top of the casing 3 for connecting with the vacuum pipe The exhaust passage 1 connected by the auxiliary oil pump on the road, the oil and gas inlet passage 6 and the exhaust passage 1 are both in communication with the inner cavity of the housing 3, and a floating ball 4 is arranged in the inner cavity of the housing 3; : An exhaust valve 2 is fixed on the top of the float 4, and the exhaust valve 2 includes a main valve 7 and a pilot valve 8;

[0020] The bottom of the valve body 9 of the main valve 7 is fixed on the top of the float 4, the valve core 10 on the top of the valve body 9 matches the valve port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com