Sand core exhaust method of complicated casting

A method of venting and sand core technology, which is applied in the direction of molds, cores, and mold components, can solve problems such as sand core venting difficulties, and achieve the effects of easy procurement, good venting effect, and smooth venting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] When molding and closing the box, the vent pipe is buried in the core head of the air channel sand core and the water channel sand core, so that the sand core can communicate with the outside atmosphere through the vent pipe; the material selection of the vent pipe: steel pipe is used as the vent pipe for cast iron castings; for Aluminum alloy castings, choose glass tubes as vent pipes.

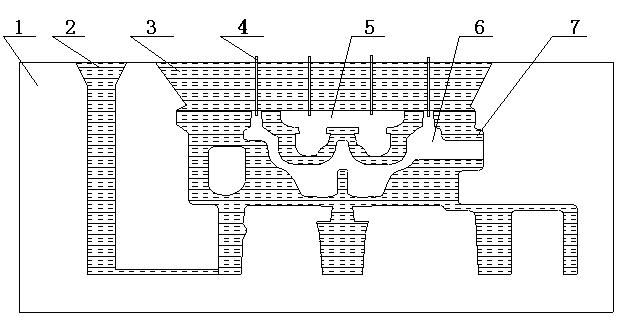

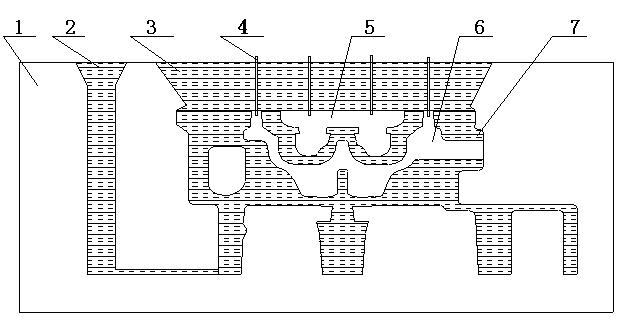

[0011] Such as figure 1 As shown, the vent pipe 4 is buried in the core heads of the air channel sand core 5 and the water channel sand core 6 when molding and closing the case, so that the sand core can communicate with the outside atmosphere through the vent pipe. During pouring, the gas generated by the heating of the sand core is smoothly discharged out of the sand core through the vent pipe, thereby avoiding the gas entering the molten metal and causing the pores of the casting to be defective.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com