Cold-hot compound stamping forming method for steel plate with ultrahigh strength

A high-strength steel plate and stamping forming technology, applied in the field of hot stamping, can solve the problems of high cost and low laser cutting accuracy, and achieve the effects of improving production efficiency, ensuring dimensional accuracy and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

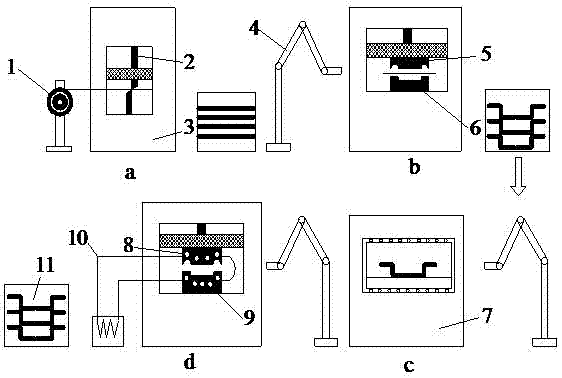

[0014] The content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0015] The figure shows the cold-hot composite stamping forming method. The steel plate 1 is first blanked on the blanking press 3, and then transferred to the cold forming press by the manipulator 4. Because the steel plate before hot forming has low hardness and good plasticity After the stamping of the cold forming die, the precise forming, edge trimming, punching and other operations of the steel plate can be completed. The cold formed stamping parts are transferred to the heating furnace by the manipulator for heating and kept for a period of time to make the plate completely austenitic. The heating temperature and holding time are affected by many factors such as the thickness of the steel plate, thermal physical properties, and the heating efficiency of the heating furnace. Generally, for plates with a thickness belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com