Method and device for strengthening underwater laser micro shot blasting of fastener hole

A shot peening and underwater laser technology is applied to the device for realizing this method, the underwater laser micro shot peening of fastening holes, and the strengthening of the inner wall of fastening holes, which can solve the problem of reduced shock wave energy and large alternating current. The load is harsh in the working environment, and the compressive stress layer cannot be generated to achieve the effect of ensuring balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

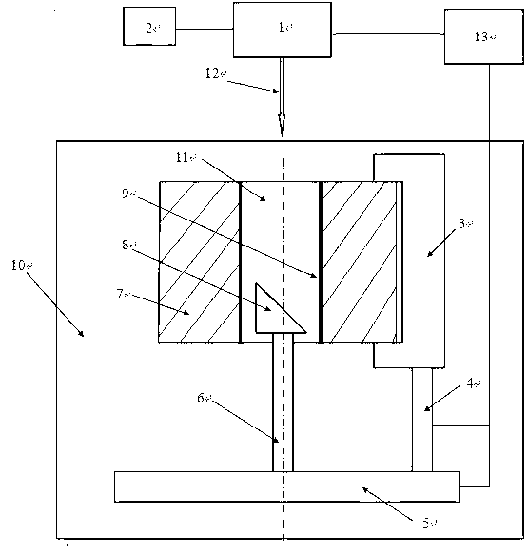

[0030] A fastening hole laser micro shot peening strengthening device, such as figure 1 As shown, it includes: a laser 1, a laser control device 2, a water tank 10, a five-axis worktable 5, a fixture I3, a fixture II6, a feeding device 4, a total mirror 8 and a numerical control system 13.

[0031] Fixture II6 is installed on the five-axis table 5; fixture I3 is connected to the five-axis table 5 through the feed device 4; the total mirror 7 is installed on the fixture II6; the laser 1 is located opposite to the five-axis table 5; the water tank 10 is located on the Below the five-axis table 5 ; the numerical control system 13 controls the output pulse of the laser 1 , the feed cycle of the feeding device 4 and the movement of the five-axis table 5 .

Embodiment 2

[0033] The specific steps of implementing a method for underwater laser micro shot peening of fastening holes are:

[0034] (1) Place the five-axis workbench 5 in the water tank 10;

[0035] (2) Install the workpiece 7 on the fixture Ⅰ3, and coat the inner wall of the fastening hole 11 with an absorbing layer (black paint) 9, and then install the total reflection mirror 8 on the fixture Ⅱ6 to ensure that the angle between the total reflection mirror 8 and the horizontal plane is 45°;

[0036] (3) Set the pulse energy of laser 1 to 0.5 J, the spot diameter D to 0.2 mm and the pulse width to 10 ns through the laser control device 2;

[0037] (4) Adjust the five-axis worktable 5 by the numerical control system 13 so that the incident laser beam 12 is coaxial with the fastening hole 11 and the focus of the laser beam 12 is positioned on the total reflection mirror 8;

[0038] (5) Adjust the feeding device 4 through the numerical control system 13, so that the laser beam reflecte...

Embodiment 3

[0042] The parameters of the high-power pulsed laser 1 in Example 2 were changed to a pulse energy of 1 J, a spot diameter of 0.5 mm and a pulse width of 20 ns, and other methods and steps remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com