Frame beam column fire-resistant node with catenary effect and construction method thereof

A catenary and effect technology, which is applied in the direction of fire protection, building material processing, building components, etc., can solve the problem of damage to the collapse resistance of structures, and achieve the effects of reducing residual deformation, relieving thermal expansion stress, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

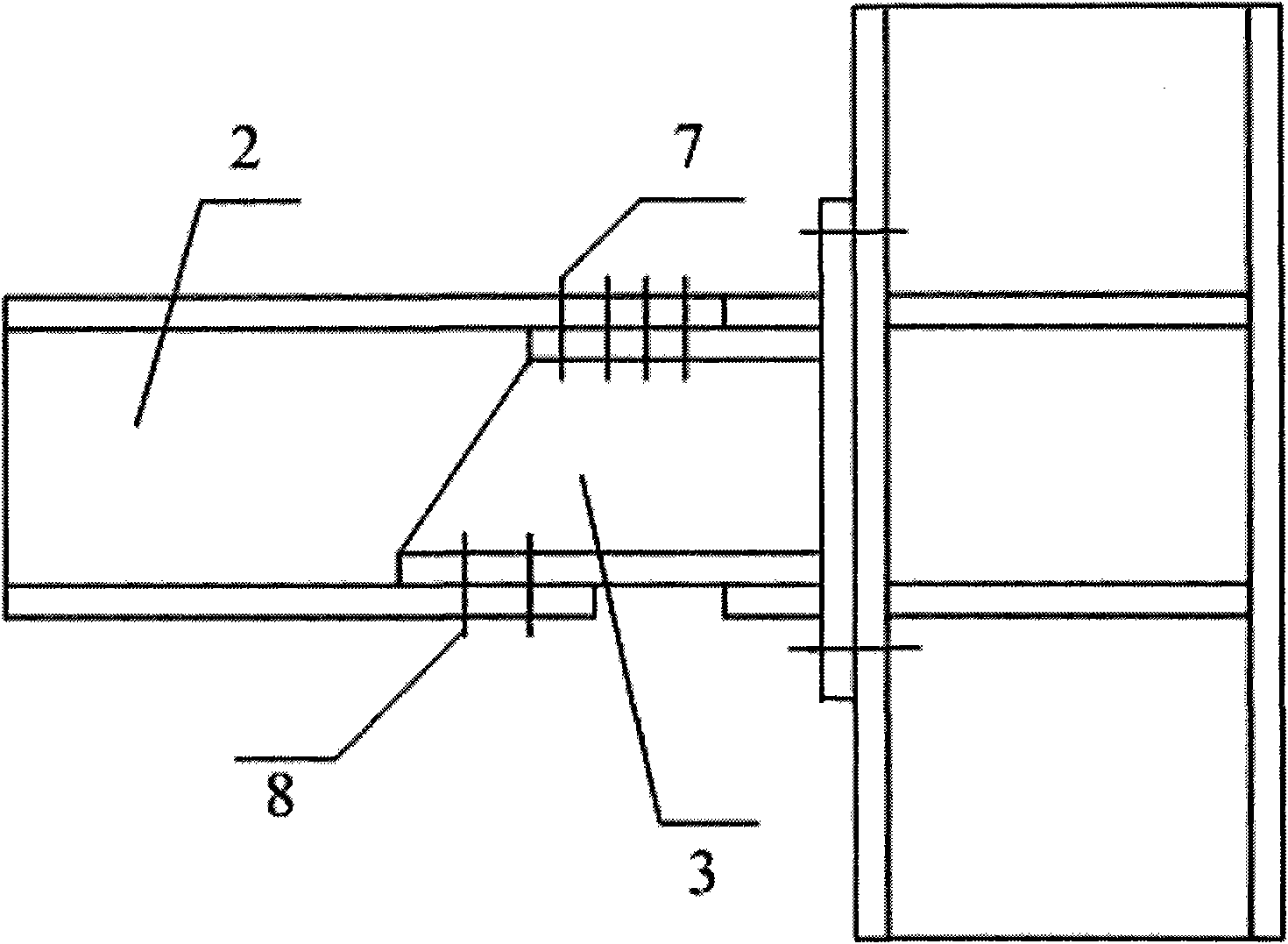

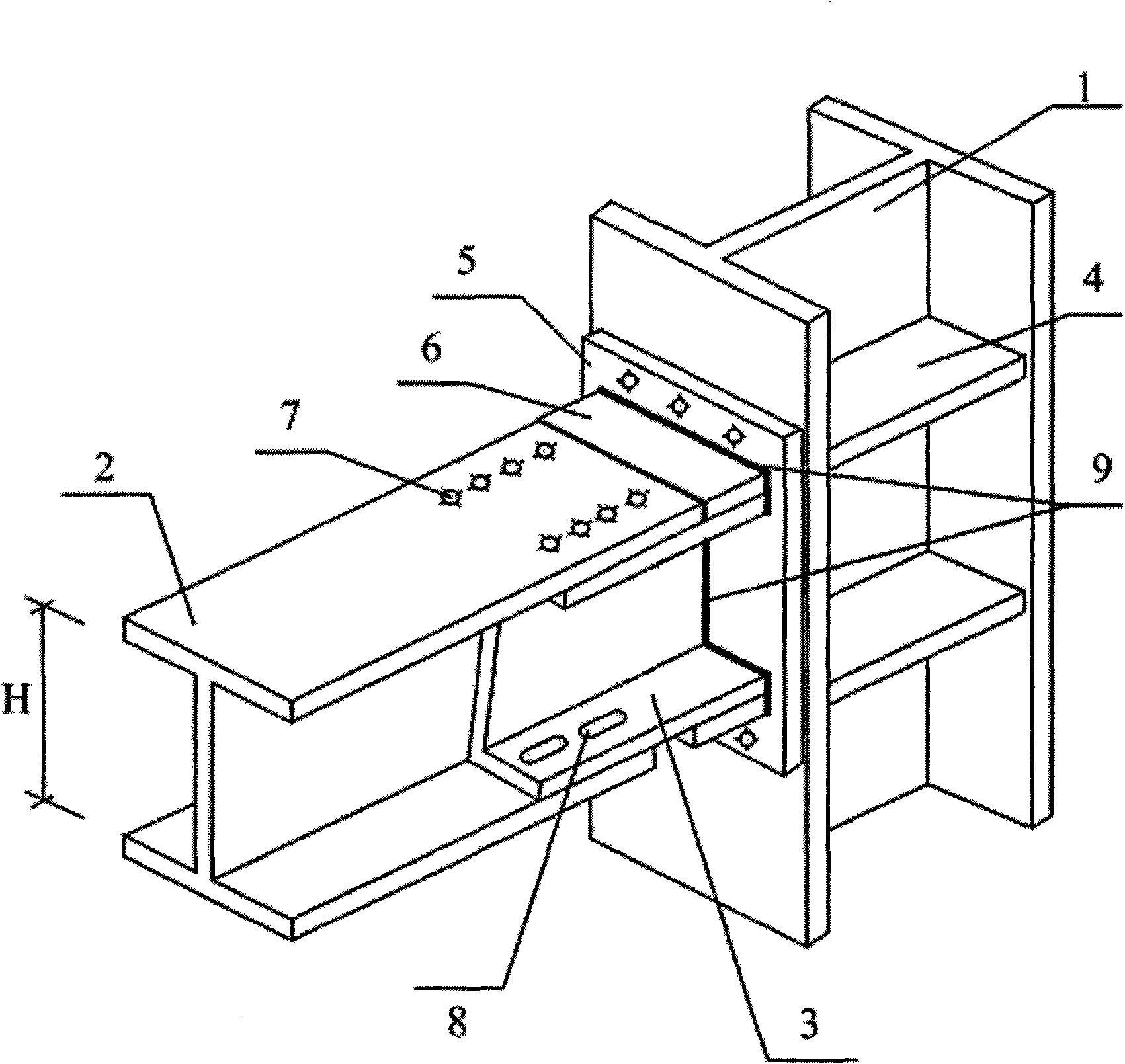

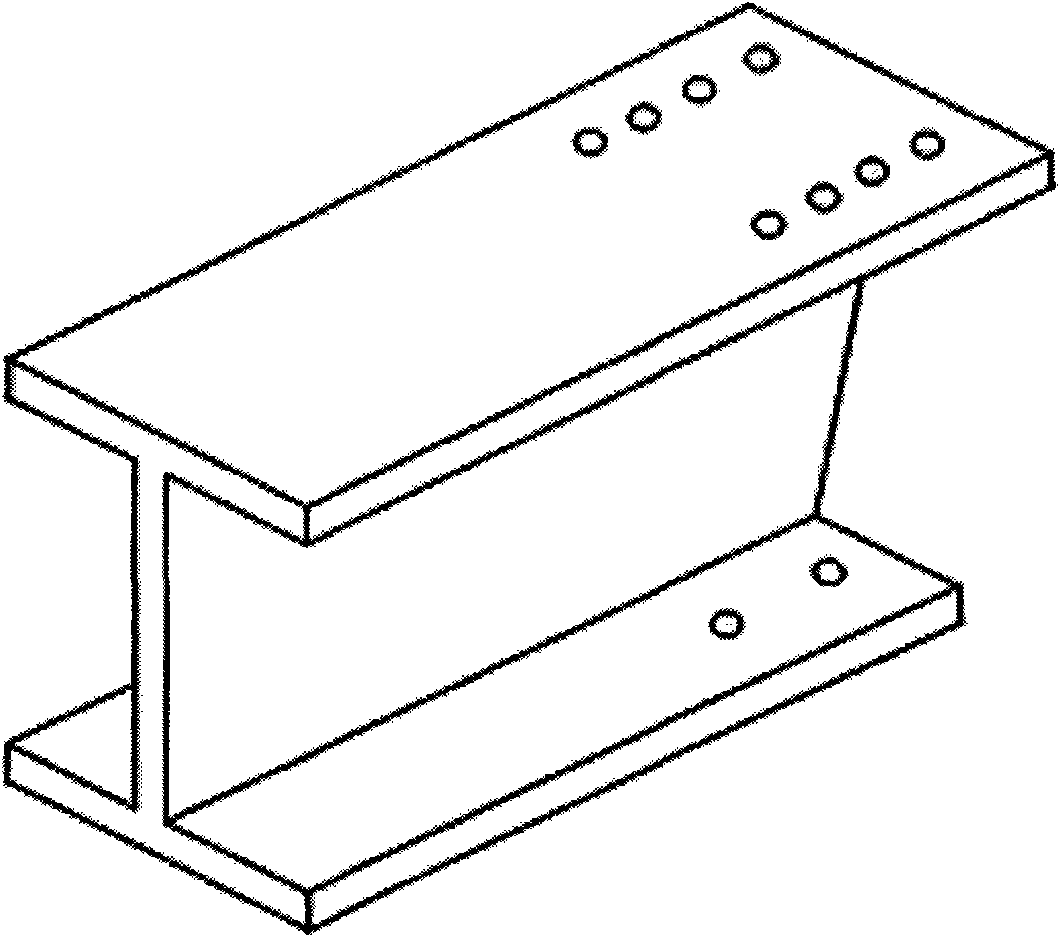

[0031] Examples see Figure 1 to Figure 6 Shown: a frame beam-column fire-resistant joint with catenary effect, including column 1, steel beam 2 and end plate 5, end plate 5 is connected to the side of column 1 by bolts, and steel beam 2 is connected to the side of end plate 5 , the steel beam 2 is I-beam or H-shaped steel, the end of the steel beam 2 has a triangular incision, the cut part is the lower flange and the web, and the cut length of the lower flange is 40% of the overall height H of the steel beam. % to 70%; the notch of the beam is connected with a trapezoidal connecting key 3, the trapezoidal connecting key 3 is composed of double channel steel opposite to the web, its longitudinal section is a positive trapezoid, and the overall height of the trapezoidal connecting key 3 is the same as that of the steel beam 2 The height of the web plate of the trapezoidal connecting key 3 is the same, the upper length L of the trapezoidal connecting key 3 is 1 to 1.5 times the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com