Seal And Seal Arrangement

A technology of seals and sealing lips, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of increased sealing surface wear, leakage in high-pressure areas, etc., and achieve a reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

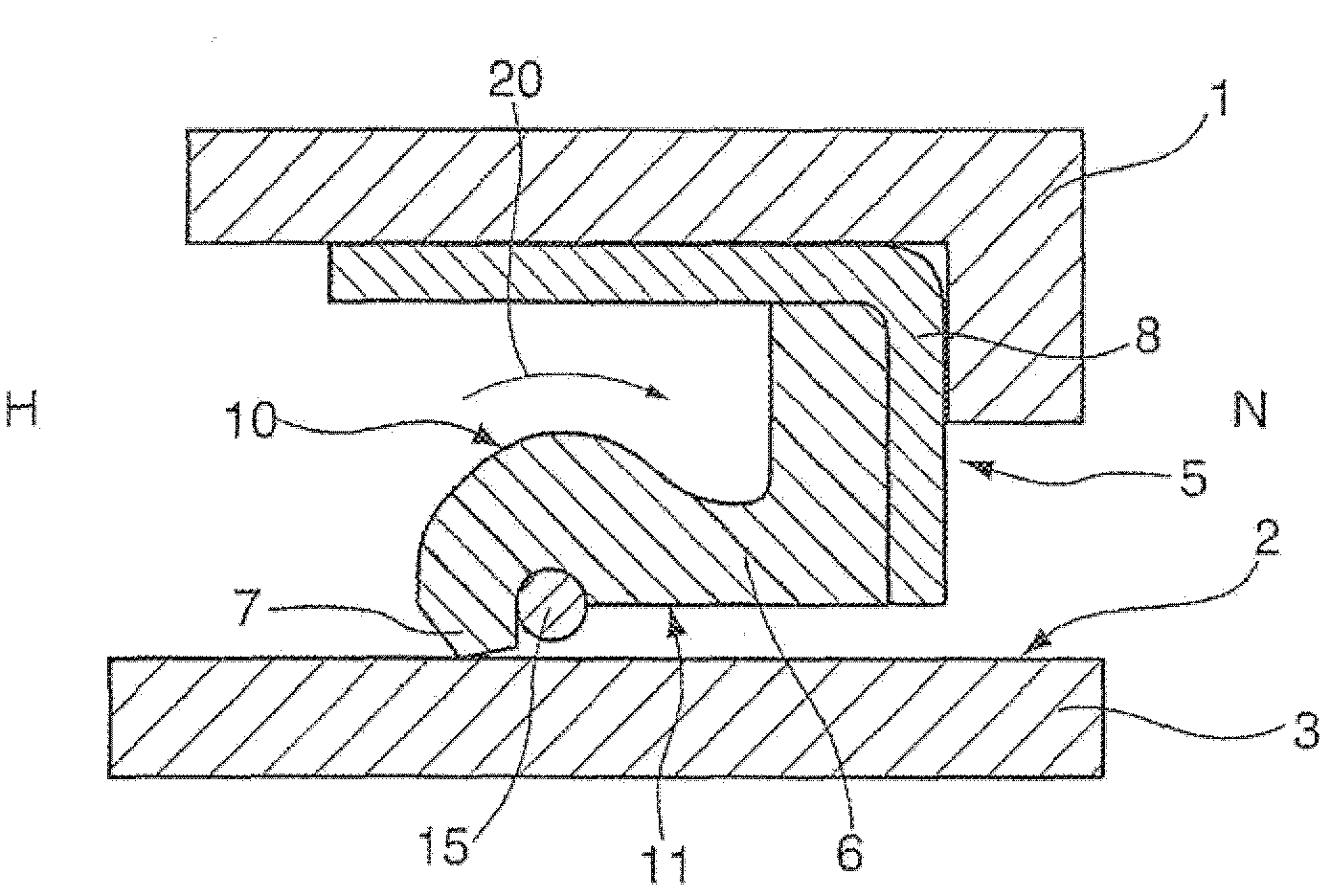

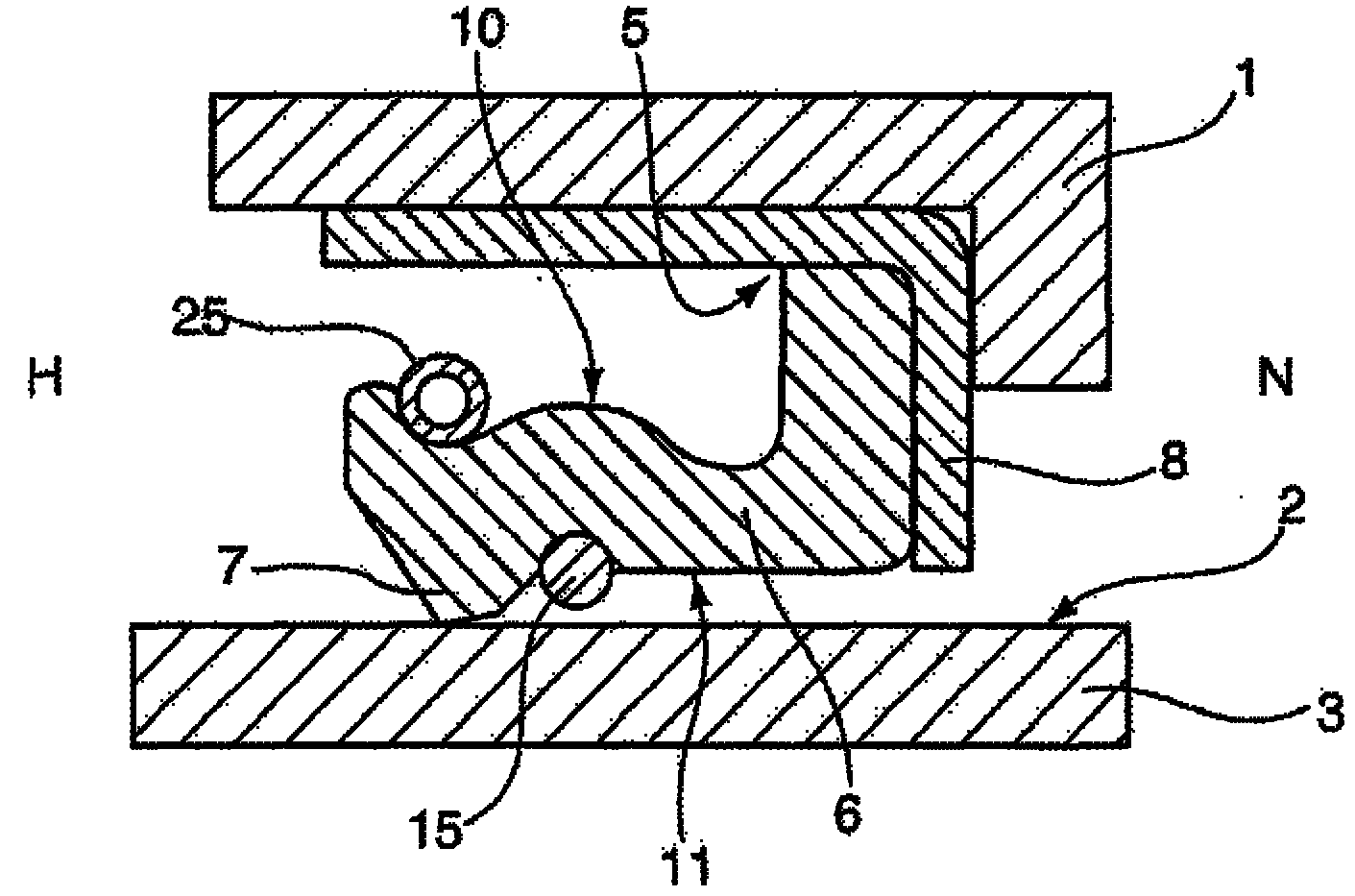

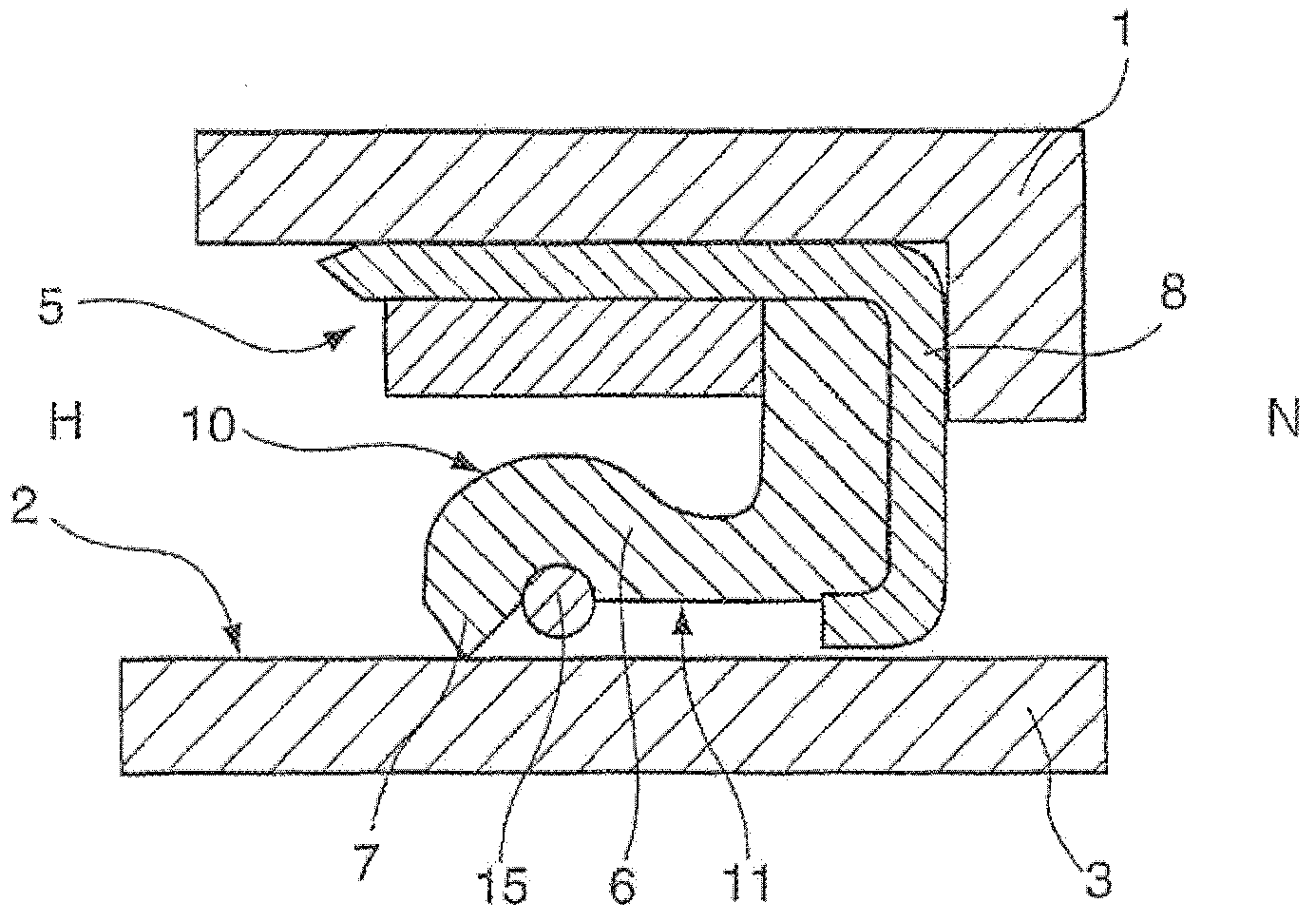

[0026] Figures 1 to 12A cross-section according to the invention is shown in each case as a sealing device, only the half of the cross-section being shown symmetrically with respect to the axis of rotation. Each sealing device has a first mechanical part 1 and a second mechanical part 3 which has a sealing surface 2 to be sealed and which is movable relative to the first mechanical part 1 . A seal holder is provided on the first machine part 1, which seal holder has an angular bearing surface for supporting a retaining element 5 of a seal according to the invention formed as a sealing ring for sealing The position of the part is fixed in the seal receiving structure. A sealing lip 6 with a sealing edge 7 is correspondingly connected to the holding element 5 . The retaining elements 5 of the individual seals each have a reinforcing element 8, wherein in Figures 1 to 11 In an embodiment of the present invention, the reinforcing element 8 has a substantially L-shaped cross se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com