Device and method for forming variable cross-section thin-wall conical carbon fiber perform

A carbon fiber prefabricated body and molding device technology, which is applied in the field of variable cross-section thin-walled conical carbon fiber prefabricated body molding and variable cross-section thin-walled conical carbon fiber prefabricated body molding device field, which can solve the problem of loose fit, low product volume fraction, fiber Reinforcement loose and other problems, to achieve the effect of reducing molding difficulty, excellent mechanical properties, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

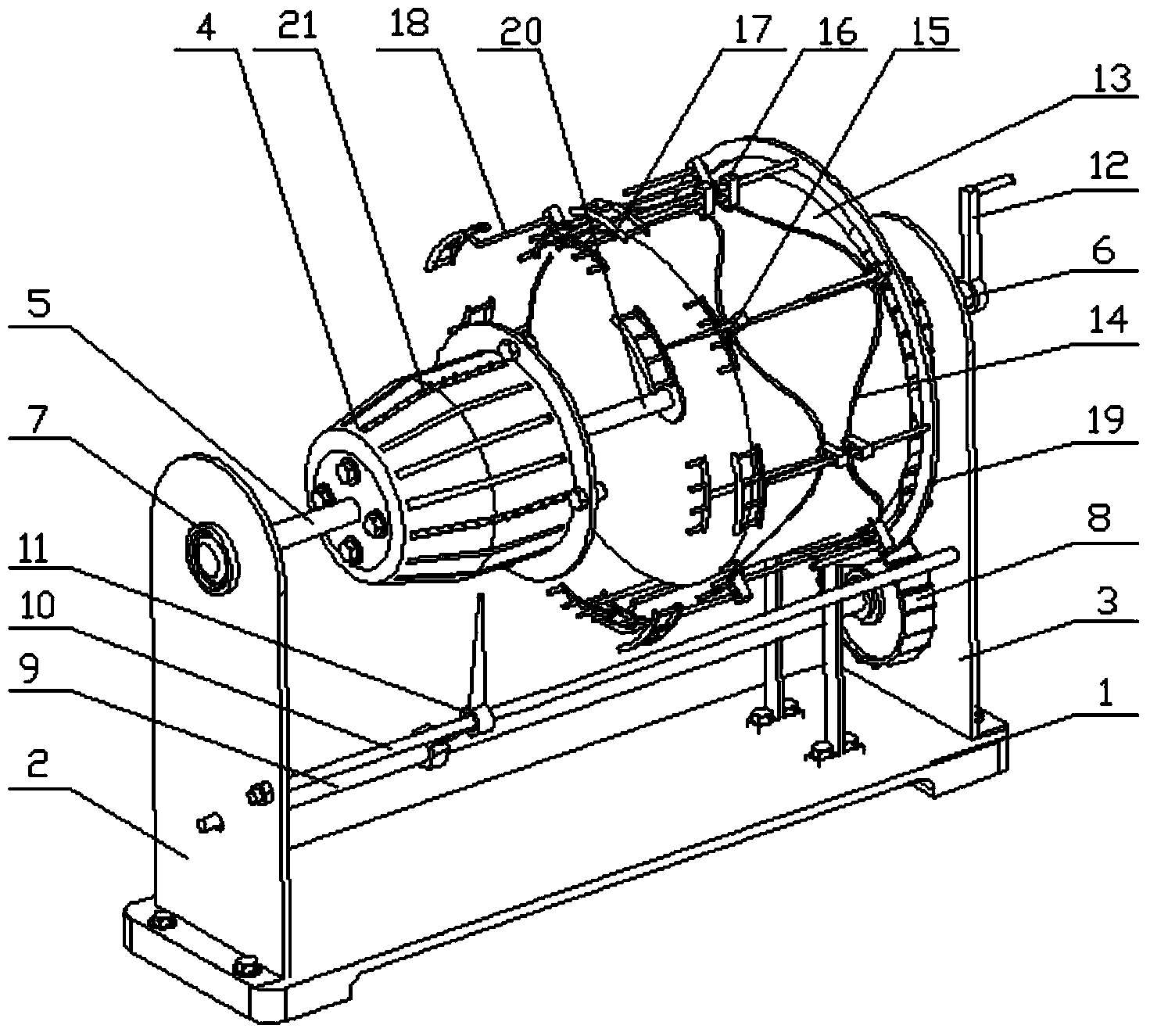

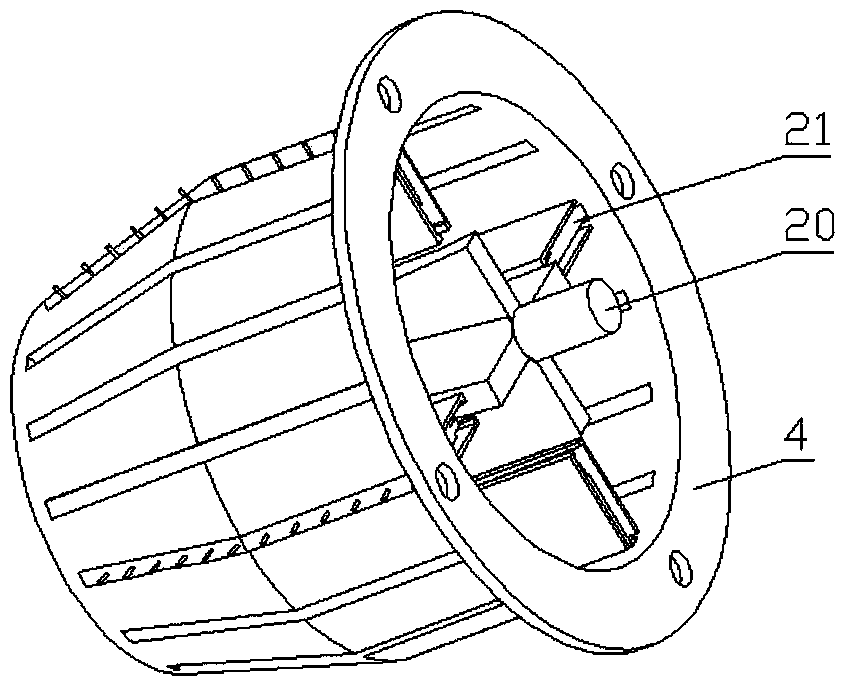

[0023] A method for manufacturing a continuous carbon fiber variable cross-section thin-walled conical prefabricated body, using 12K carbon fiber unidirectional cloth and 3K carbon fiber bundles, laying and winding a total of 11 layers.

[0024] Step 1: The first layer is covered with 12K fiber unidirectional cloth along the mold. Cut the 12K carbon fiber unidirectional fabric into a rectangle according to the size of the variable cross-section thin-walled conical prefabricated body. The fiber arrangement direction is consistent with the axial direction of the variable cross-section thin-walled conical prefabricated body. 12K carbon fiber unidirectional fabric, so that it can be laid one circle along the winding mold 4 to form the complete shape of the tapered prefabricated body with variable cross-section and thin wall. The upper flange part is cut into small pieces along the axial direction of the 12K carbon fiber unidirectional cloth fiber, and folded inwards section by sec...

Embodiment 2

[0030] A method for manufacturing a continuous carbon fiber variable cross-section thin-walled conical prefabricated body, using 6K carbon fiber unidirectional cloth and 6K carbon fiber bundles, laying and winding a total of 15 layers.

[0031] Step 1: The first layer is covered with 6K carbon fiber unidirectional cloth along the mold. Cut the 6K carbon fiber unidirectional fabric into a rectangle according to the size of the variable cross-section thin-walled conical prefabricated body. The fiber arrangement direction is consistent with the axial direction of the variable cross-section thin-walled conical prefabricated body. The carbon fiber unidirectional cloth can be laid one circle along the winding mold 4 to form the complete shape of the thin-walled tapered prefabricated body with variable cross-section. The upper flange part is cut into small pieces along the axial direction of the 6K carbon fiber unidirectional cloth fiber, and folded inwards section by section to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com