Optical tool regulator for excimer laser micromachining system

An excimer laser and micromachining technology, which is applied in the field of micro-nano science, can solve the problems of low-dimensional adjustment, the inability to use the excimer laser micromachining system optical path, time-consuming and labor-intensive problems, and achieve reliable long-term stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

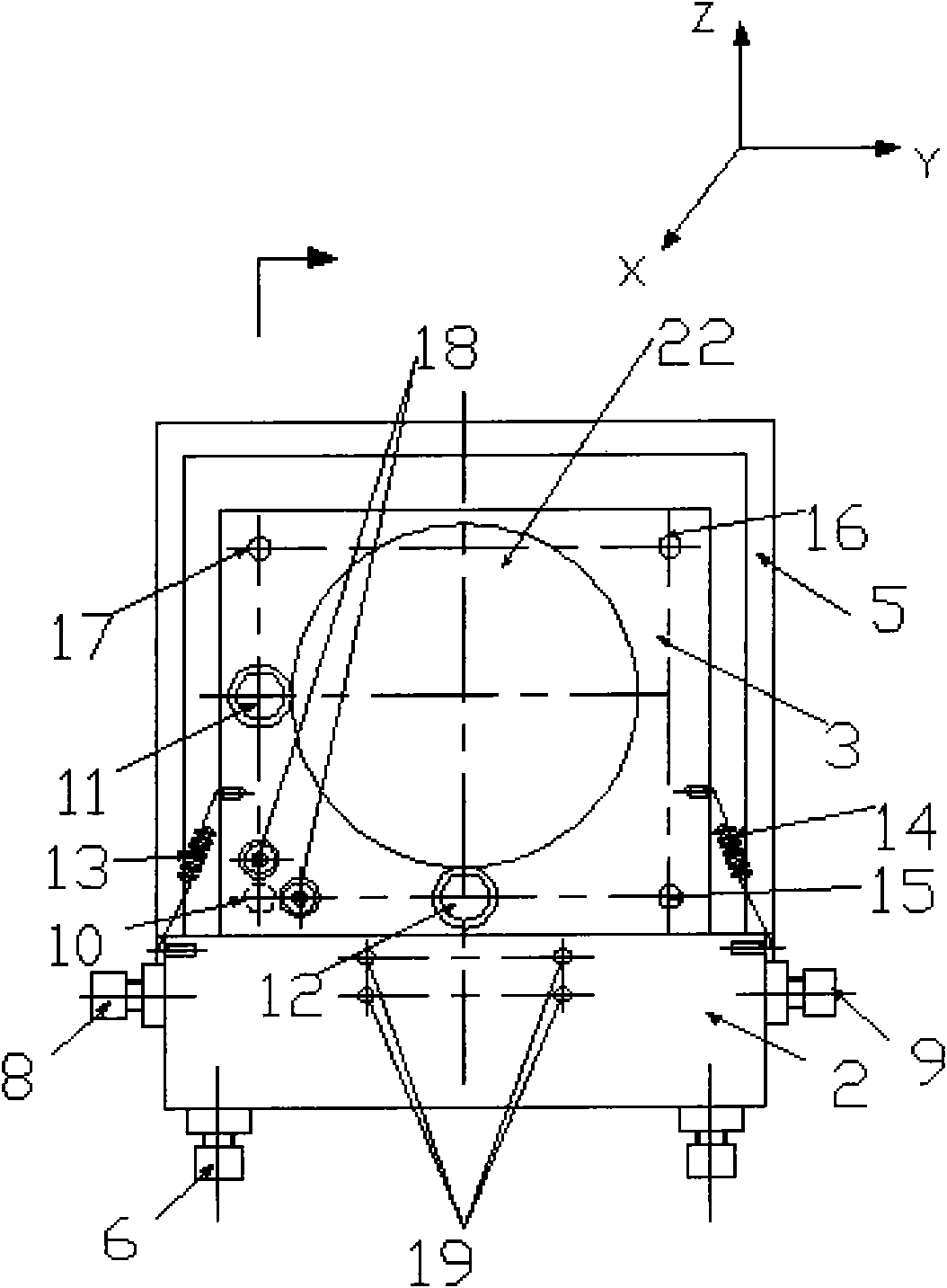

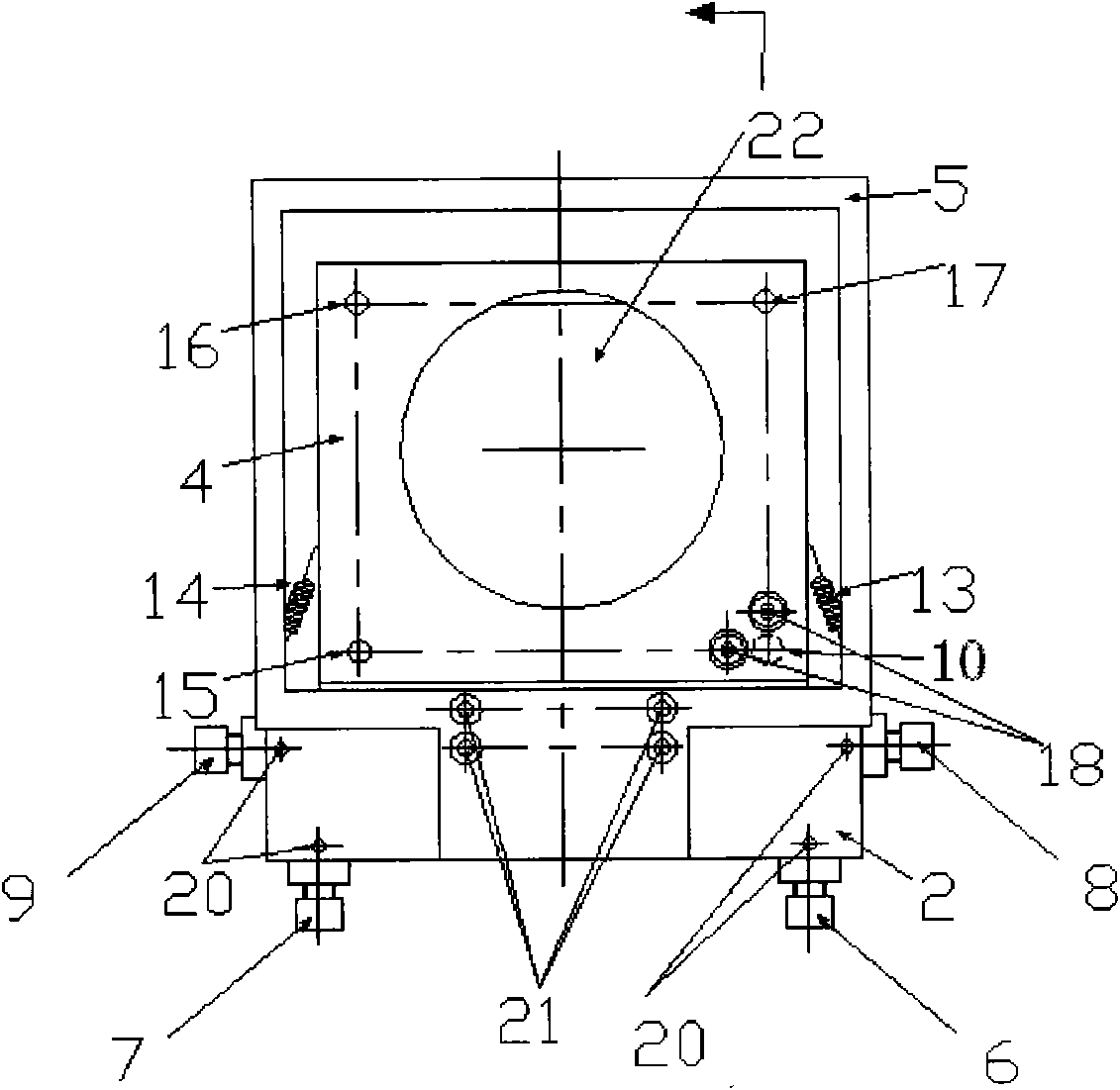

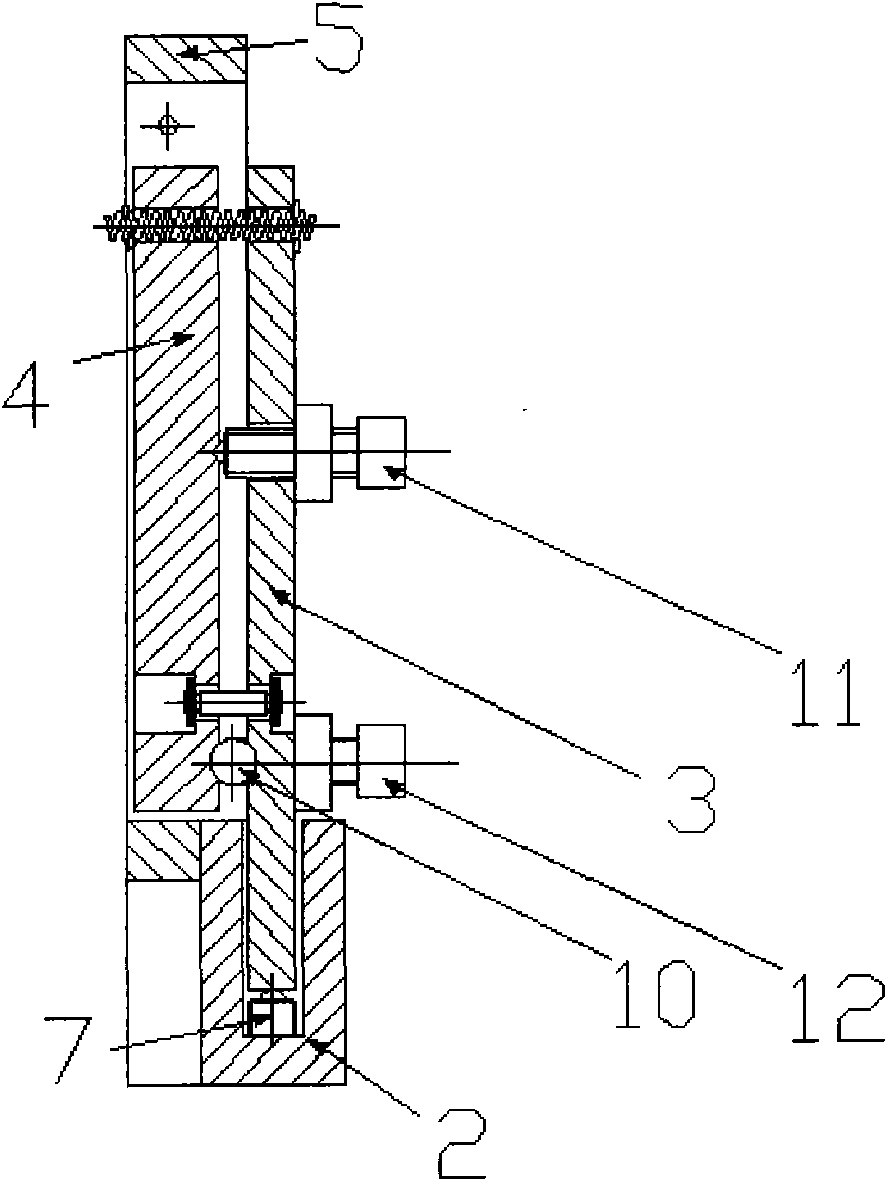

[0024] Combine below figure 1 , figure 2 , image 3 , Figure 4a ~b describes Embodiment 1 of the present invention in detail.

[0025]The present embodiment mainly includes sliding seat 1, adjusting seat 2, support plate 3, mirror frame 4, tight locator 5, reflective inclined frame seat 32, fixes a reflective mirror with it in the present embodiment. The sliding seat 1 is placed on a common optical guide rail, and the reflective inclined frame seat 32 and the sliding seat 1 are provided with three corresponding screw holes, which are connected by bolts and nuts. Four fixed screw holes 21 are established on the side of the adjustment seat 2, and three screw holes are established on its bottom surface, and four screw holes and three screw holes are also respectively correspondingly established on the two faces of the inclined groove of the reflective inclined frame seat 32, and are connected with the adjustment seat. The side and bottom surface of 2 are connected by bolts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com