High-performance environment-friendly single-component hydrophobic polyurethane grouting material and preparation method thereof

An environmentally friendly, polyurethane technology, used in the field of grouting and waterproof plugging materials, can solve problems such as poor hydrophilicity, and achieve the effects of good plasticizing effect, high dimensional stability and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

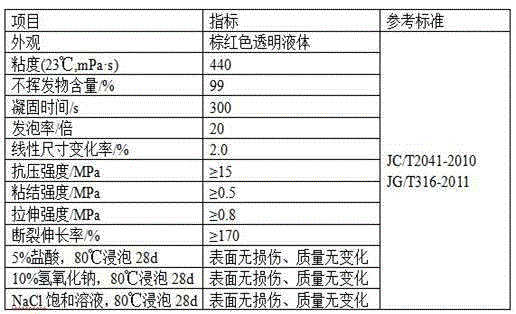

Embodiment 1

[0045] Add 100g of polyether polyol N204 to 90.4g of hexamethylene-1,6-diisocyanate, raise the temperature to 75°C for 3 hours, then add 40.5g of n-butanol, continue the reaction for 2 hours, cool down and discharge to obtain liquid polyurethane plasticized agent.

[0046] Weigh 12g polyether polyol N210, 5g polyether polyol N220, 10g polyester polyol PS-3152, 3g polyether polyol 303, 1g polytetramethylene ether glycol 1000, 1g hydroxyl-terminated polybutadiene together Put it into the reaction kettle, vacuum dehydration at -0.08~-0.1MPa, 110~120°C for 2 hours (raw material moisture content ≤0.05%), cool down to 55°C, add 113g polyphenyl polymethylene poly Isocyanate (-NCO content 30.5~32%), after stirring for 30 minutes under nitrogen atmosphere, heat up to 70 ° C, react for 3 hours, after the reaction is completed, the temperature drops to 50 ° C to obtain a polyurethane prepolymer; to the above polyurethane prepolymer Add 7.5g liquid polyurethane plasticizer, 15g diatomit...

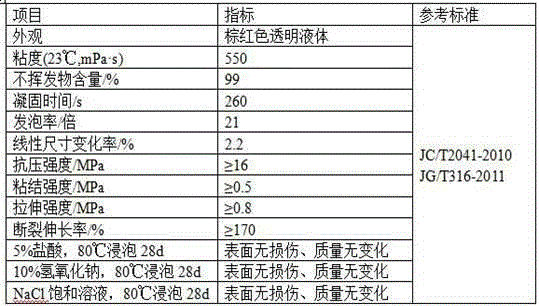

Embodiment 2

[0050] Add 100g of polyether polyol N210 into the reaction vessel, vacuum dehydrate at -0.08~-0.1MPa, 110~120°C for 2 hours, cool down to 60~65°C, add 33.6g of 1,6-hexamethylene diisocyanate, and heat up to 80°C React for 2 hours, then add 14.4g of n-butanol, continue to react for 2 hours, cool down and discharge to obtain a liquid polyurethane plasticizer;

[0051] Weigh 20g polyether polyol N204, 10g polyether polyol 303, 5g PTMEG1800, 1g hydroxyl-terminated polybutadiene Polybd R-45HT (molecular weight 2700~2900, hydroxyl value 42~50mgKOH / g,), 1g hydroxyl-terminated polybutadiene Add epichlorohydrin (molecular weight 2800~3000, hydroxyl value 33~40mgKOH / g, functionality 1.8~2) into the reaction vessel together, vacuum dehydration for 2 hours, after dehydration (moisture content of raw materials ≤0.05%), cool down to 55~ 80°C, add 143g of PAPI to the reaction vessel, heat and stir for 30min under nitrogen atmosphere, then raise the temperature to 70°C, react for 3 hours, aft...

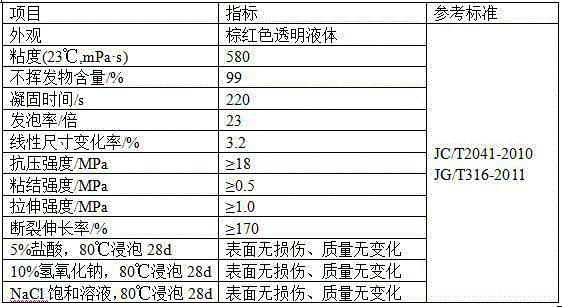

Embodiment 3

[0055] Add 100g of polyether polyol N220 into the reaction kettle, dehydrate at -0.08~-0.1MPa, 110~120°C for 2 hours, cool down to 60°C, add 16.8g of hexamethylene-1,6-diisocyanate, Raise the temperature to 80°C for 2 hours, then add 10 g of n-hexanol, continue the reaction for 2 hours, cool down and discharge to obtain a liquid polyurethane plasticizer;

[0056] Weigh 12g polyether polyol N204, 5g polyether polyol N220, 10g polypropylene carbonate polyol (molecular weight 1800~2200, hydroxyl value 45~55mgKOH / g), 3g polyether polyol 303, 1.1g PTMEG650, 5g hydroxyl-terminated polybutadiene Polybd CS-15 (molecular weight 2800~3600, hydroxyl value 34~48mgKOH / g), 1g hydroxyl-terminated polyepichlorohydrin (molecular weight 2800~3000, hydroxyl value 33~40mgKOH / g), together Put it into the reaction vessel, vacuum dehydrate for 2 hours, after dehydration (moisture content of raw materials ≤ 0.05%), cool down to 55~80°C, add 250g of PAPI to the reaction kettle, keep stirring for 30min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com