Gob-side entry retaining method for putting top waste rock down to achieve roadway side packing

A technology of retaining entry and gangue entry, which is applied in the direction of filling, earthwork drilling, safety devices, etc., and can solve problems such as the stability of difficult surrounding rocks and cost a lot of money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

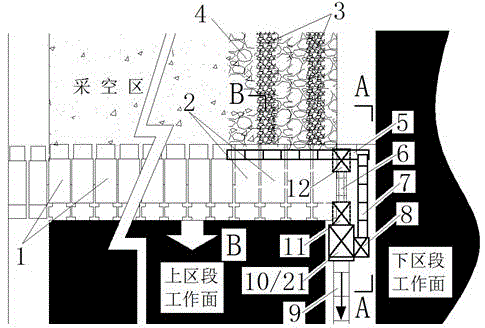

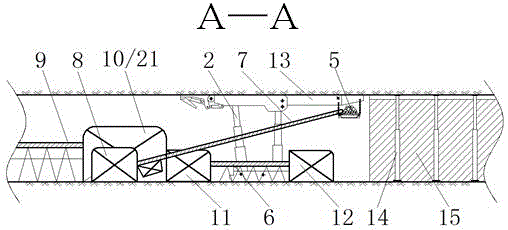

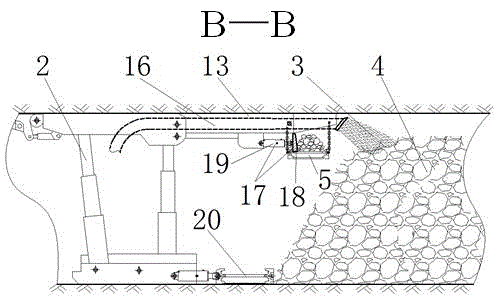

[0020] refer to figure 1 , 2 , 3, 4, and 5 illustrate Embodiment 1 of the present invention. When caving coal mining, first set up a single hydraulic prop 14 and a baffle plate 15 at the side of the side of the gob in the goaf to prevent gangue from entering Keep the roadway. During the advancing process of the working face in the upper section, after the coal discharging process of the working face is completed, the coal discharging work will be completed, and then the top coal caving support 1 will be directly put down the gangue above the goaf, and the rear scraper will pass through. The conveyor 20 transports to the end of the working face, passes through the rear loader 12, the connecting conveyor 6, and the front loader 11, and transports it to the crusher 10. After simple crushing, the gangue is transferred to the side loader 8 and transferred to the conveyor 7 , and then reach the suspension scraper conveyor 5 suspended on the hydraulic support 2 of the working face a...

Embodiment 2

[0024] refer to figure 1 , 2 , 3, 4, and 5 illustrate Embodiment 2 of the present invention. For mines equipped with the conditions for installing coal and gangue separation devices, when mining top coal, first set up a single hydraulic pressure The pillars 14 and the baffles 15 prevent gangue from being strung into the roadway. During the advancement of the upper section of the working face, excessive coal discharge is adopted, passing through the rear scraper conveyor 20, the rear reloader 12, the connecting conveyor 6, The pre-loader 11 is transported to the coal and gangue separation device 21, and the separated coal is directly transported out of the rear shaft through the main transport belt conveyor 9, and the separated gangue is transported back to the goaf on the side of the roadway, so that after treatment The waste rock is piled up and filled in the goaf on the side of the roadway, forming a gangue wall to serve as roadside support. The gangue return and accumulat...

Embodiment 3

[0026] refer to figure 1 , 2 , 3, 4, and 5 illustrate the third embodiment of the present invention. When carrying out ordinary comprehensive mechanized mining, the hydraulic support of the working face is replaced with the top-coal caving support 1, and the hydraulic support of the working face at the filling position at the side of the roadway needs to be replaced. A hydraulic support 2 with a rear roof beam is formed, and then during the advancing process of the working face in the upper section, the gangue above the goaf is directly lowered by the caving support and transported to the end of the working face, after simple crushing, reloading and transportation To the goaf on the side of the roadway retention, the processed gangue is piled up and filled in the goaf on the side of the roadway retention, forming a gangue wall to serve as roadside support. The gangue transporting out, crushing, returning, and accumulation processes involved in the above are the same as those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com