Reinforcing method for winding thermal excitation embedded shape memory alloy wires on concrete column

A memory alloy wire and concrete column technology, applied in building maintenance, construction, building construction, etc., can solve the problems of being susceptible to man-made damage, exposed reinforcement materials and anchors, etc., to achieve easy finished product protection, small stress loss, and improved The effect of bearing capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The features of the present invention and other relevant features are further described in detail in conjunction with the accompanying drawings, so that those skilled in the art can understand:

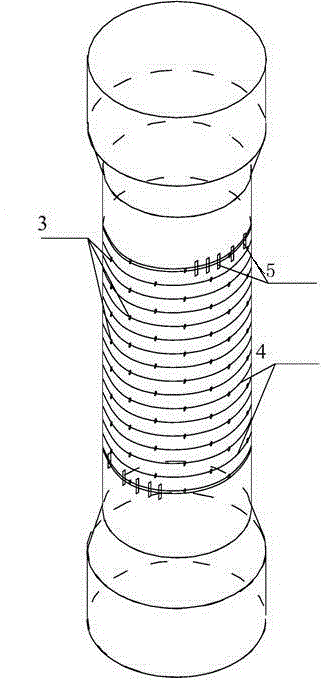

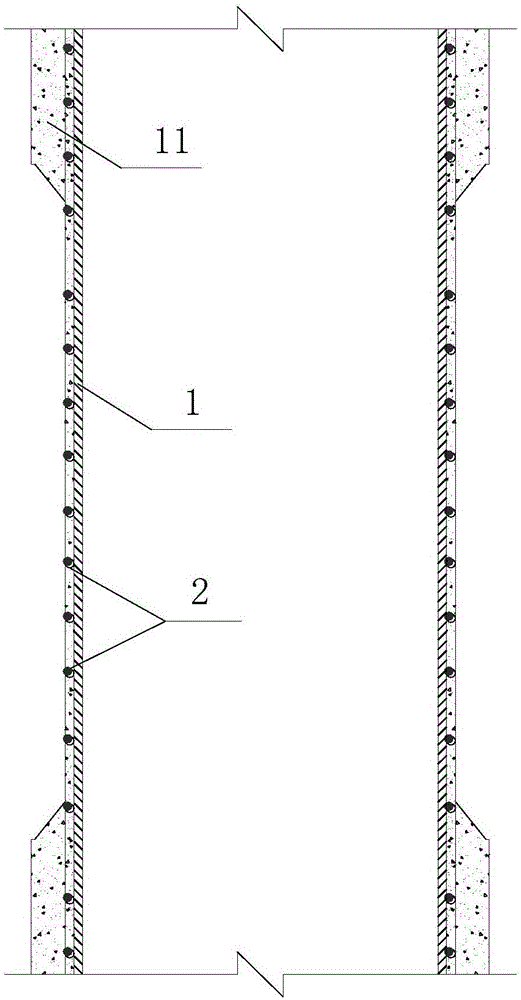

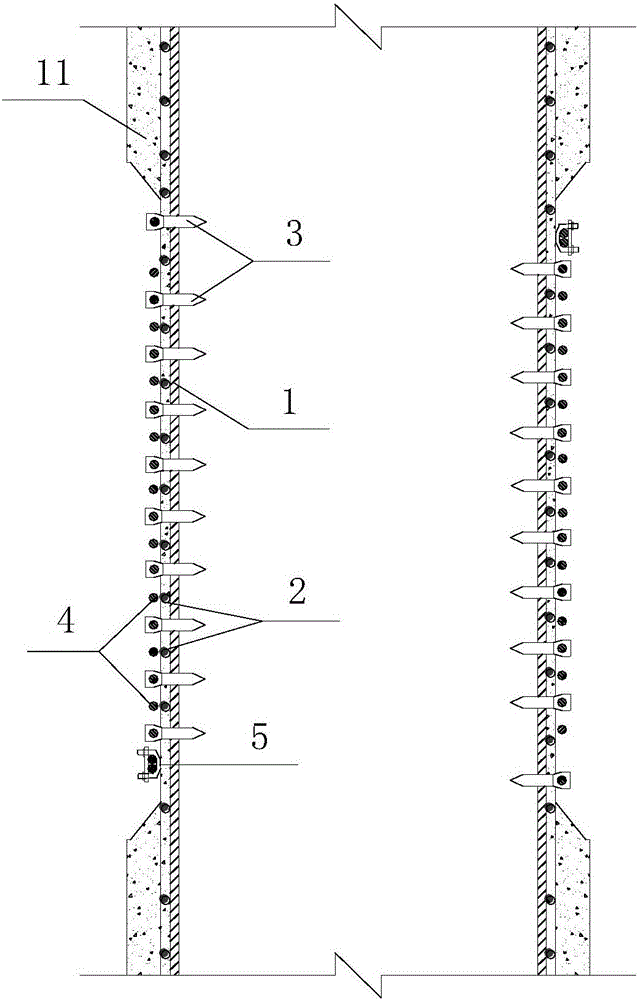

[0019] Such as Figure 1 ~ Figure 4 As shown, the present invention specifically relates to a method for reinforcing concrete columns using thermally excited embedded shape memory alloy wires, the method specifically comprising the following steps:

[0020] (1) Determine the location to be reinforced according to the force requirements of the components to be reinforced, and remove all or part of the thickness of the protective layer in the area to be reinforced;

[0021] (2) According to the force requirements of the component to be reinforced, further determine the winding range, spacing and diameter of the shape memory alloy wire 4, determine the size and position of the positioning screw 3, and use the positioning screw 3 to position the shape memory alloy wire 4 to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com