Production process for spunlace composite high temperature-resisting and corrosion-resisting filtering material

A filter material and production process technology, which is applied in the field of spunlace composite high temperature and corrosion resistant filter material, can solve the problems of filter material mechanical strength decrease, affect the service life of filter bag, and the import price is expensive, so as to improve the entanglement effect, uniform Better performance and better filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

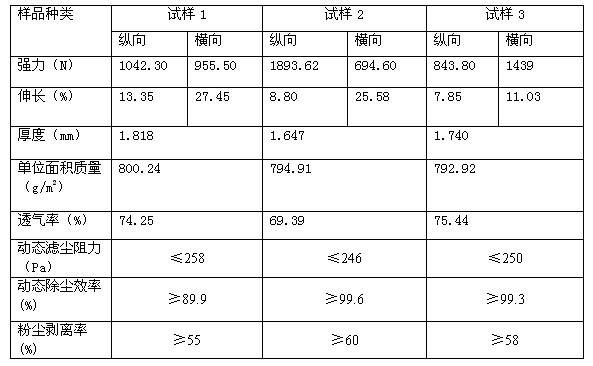

Image

Examples

Embodiment Construction

[0031] The production process of the spunlace composite high-temperature-resistant and corrosion-resistant filter material of the present invention uses polyphenylene sulfide fiber and glass fiber base cloth as raw materials; the polyphenylene sulfide fiber is first inspected, weighed and fed, and then fed into the long curtain in sequence , horizontal opener, large warehouse mixing box, fine opener, and then carding machine 1 and carding machine 2 perform layered carding, and then enter the cross-lapper 1 and cross-lapper 2 respectively for laying Then the glass fiber base cloth is sandwiched between the raw materials conveyed by the first cross-lapper and the second cross-lapper and laminated, and then enters the pre-wet process, spunlace process, dehydration process, and drying process in sequence. Drying process, coiling process.

[0032] Among them, carding machine one, the main cylinder work roll is 110m / min, the main cylinder stripping roll is 150m / min, the main cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com