Nano-composite powder core wire

A nano-composite, powder-cored wire technology, applied in metal material coating process, fusion spraying, coating, etc., can solve the problem of poor anti-corrosion, anti-slip and anti-wear performance, poor safety and reliability, and affecting the service life of marine equipment, etc. problems, to achieve the effect of improving anti-corrosion, anti-skid and anti-wear performance, prolonging service life, enhancing reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

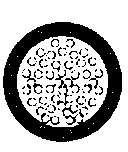

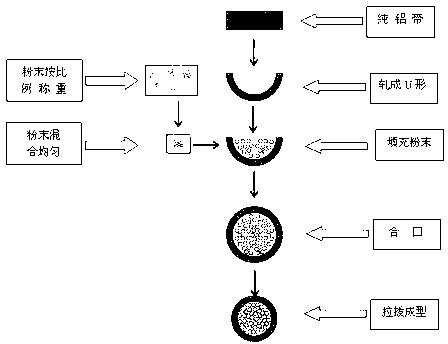

[0013] Select a 10X0.5 (width 10mm, thickness 0.5mm) aluminum strip, first roll it into a U shape, add 159.5 grams of ultra-fine aluminum powder, 160 grams of nano-titanium dioxide powder, 400 grams of nano-alumina powder, and ultra-fine chromium oxide Put 280 grams of rare earth powder and 5 grams of mixed rare earth powder in a ball mill and mix for 20 minutes, then take the mixed powder and put it into a U-shaped aluminum belt groove, and through the process of closing and drawing, a finished wire with a diameter of 2.0mm is obtained, nanocomposite The quality of the powder core is 25%~27% of the nanocomposite powder core wire.

Embodiment 2

[0015] Select a 10X0.5 (width 10mm, thickness 0.5mm) aluminum strip, first roll it into a U shape, add 50 grams of ultra-fine aluminum powder, 144 grams of nano-titanium dioxide powder, 360 grams of nano-alumina powder, and ultra-fine chromium oxide Put 250 grams of rare earth powder and 10 grams of mixed rare earth powder into a ball mill and mix for 20 minutes, then take the mixed powder and put it into a U-shaped aluminum belt groove, and through the process of closing and drawing, a finished wire material with a diameter of 1.6mm is obtained, nanocomposite The quality of the powder core is 30% of the nanocomposite powder core wire.

Embodiment 3

[0017] Select a 10X0.5 (width 10mm, thickness 0.5mm) aluminum strip, first roll it into a U shape, add 243 grams of ultra-fine aluminum powder, 180 grams of nano-titanium dioxide powder, 450 grams of nano-alumina powder, ultra-fine chromium oxide Put 310 grams of powder and 3 grams of mixed rare earth powder in a ball mill and mix for 20 minutes, then take the mixed powder and put it into a U-shaped aluminum belt groove, and through the process of closing and drawing, a finished wire with a diameter of 2.4mm is obtained, nanocomposite The quality of the powder core is 39%~40% of the nanocomposite powder core wire.

[0018] Use the BRI-400 supersonic arc coating equipment produced by Xinxiang Brilliant Machinery Remanufacturing Co., Ltd. to spray the nanocomposite powder core wire material prepared in Example 1 on the surface of the equipment to form a coating. Arc voltage: 29~32V , working current 175~200A, compressed air pressure 0.5~0.7MPa, spraying distance 180~220mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com