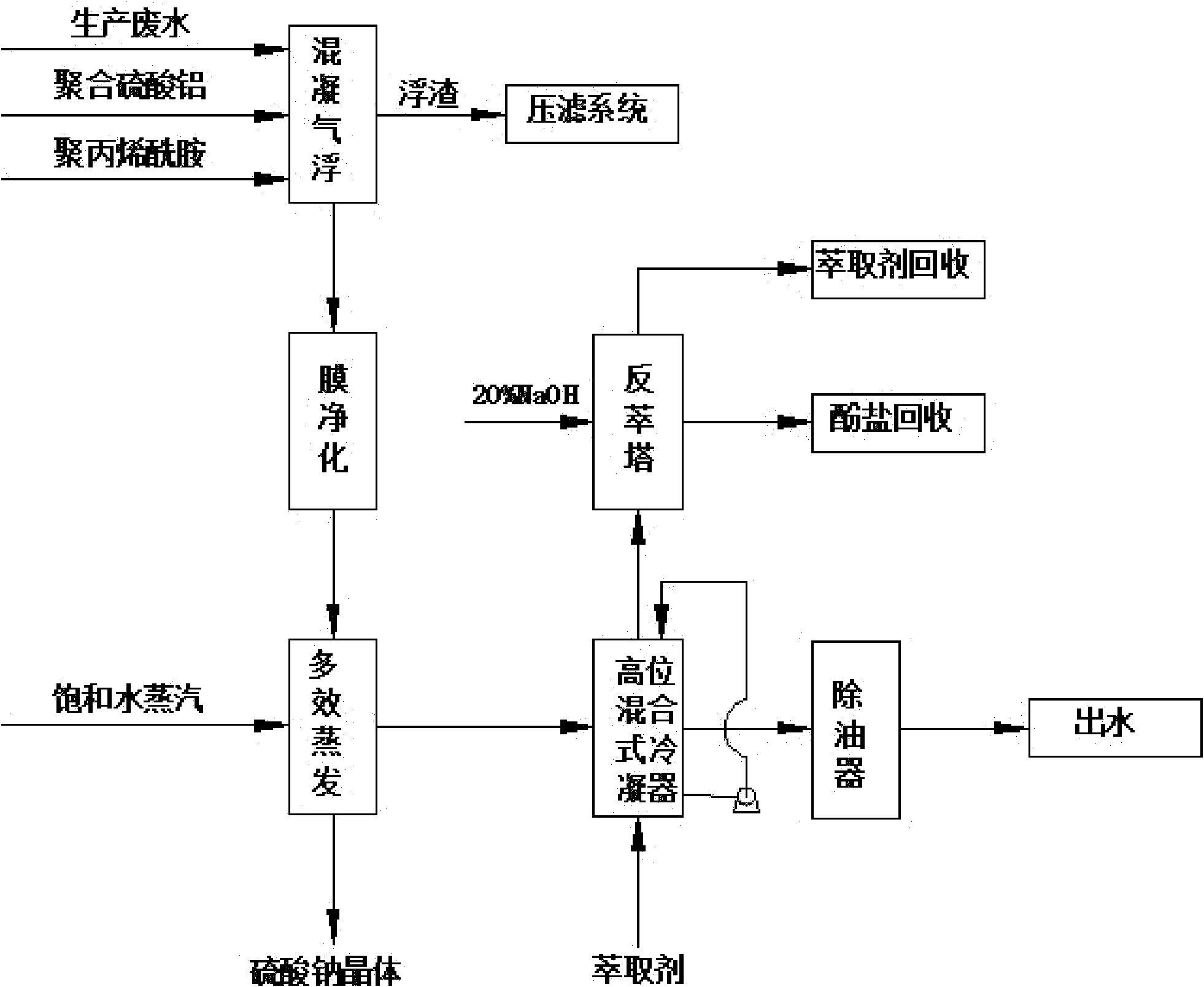

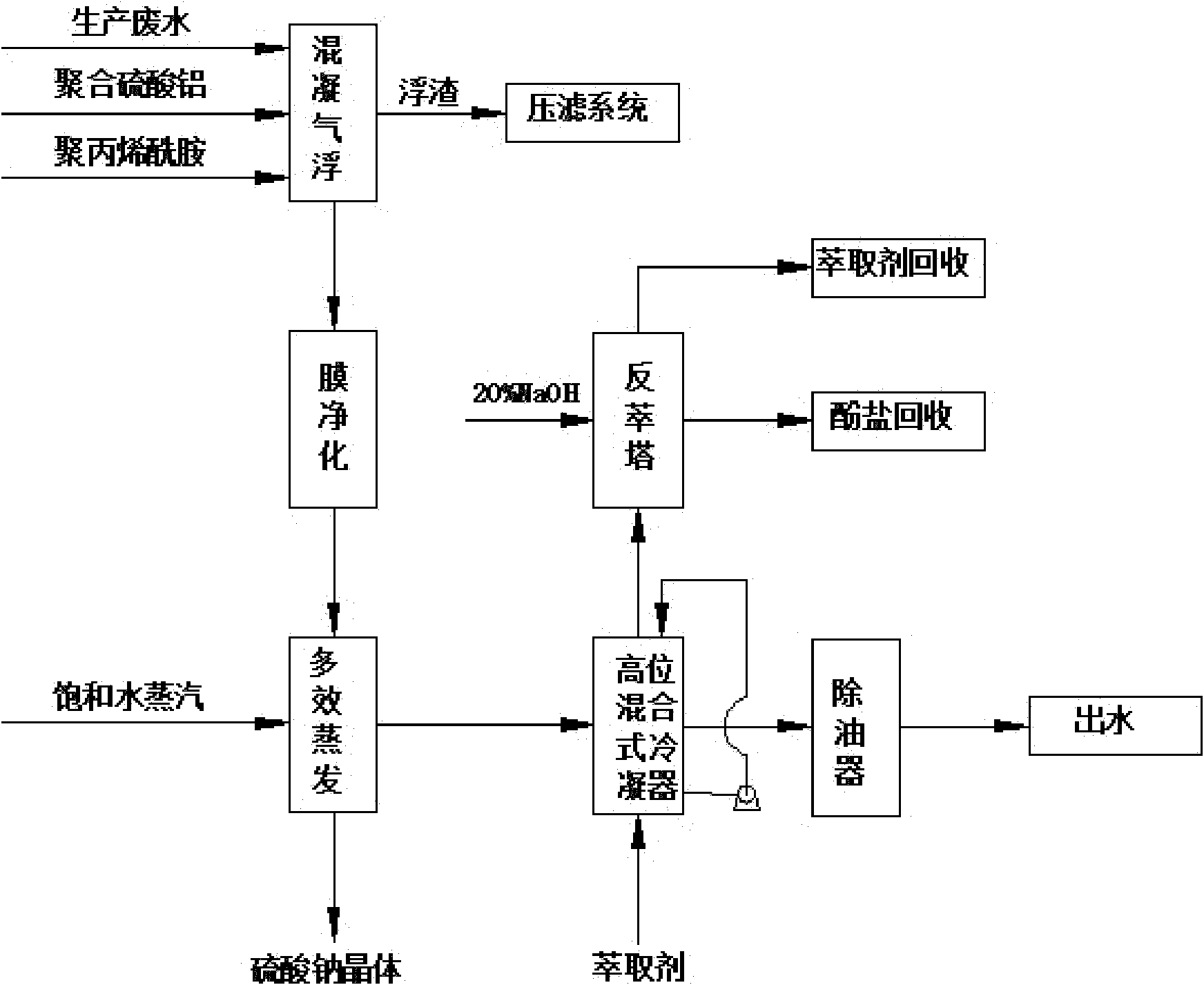

High-concentration organic and inorganic mixed wastewater treatment and recovery method

A technology of mixed wastewater and recycling methods, applied in chemical instruments and methods, preparation of organic compounds, multi-stage water/sewage treatment, etc., can solve problems such as fast adsorbent saturation time, secondary pollution, difficult adsorbent regeneration, etc. To achieve the effect of improving the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the phenol and sodium sulfate mixed waste water of certain coking plant, phenol content is 10000mg / L, and sodium sulfate concentration is 28%, narrates the specific embodiment of the present invention in detail below in conjunction with technical scheme and accompanying drawing.

[0030] 1. Preparation:

[0031] Prepare a certain proportion of polyaluminum sulfate solution and polyacrylamide solution.

[0032] It is 20% NaOH solution each 1m that the mass concentration is pumped into the stripping tower 3 .

[0033] 2. Coagulation air flotation process

[0034]After the initial crystallization of the phenol-containing wastewater with high salt content in the crystallization tank, the upper aqueous solution enters the raw water adjustment tank to adjust the pH to 6-9. Add 30ppm flocculant polyaluminum sulfate and 5ppm coagulant polyacrylamide to the waste water, and make them fully mixed in the pipeline mixer. Then the waste water directly enters the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com