Method for preparing glycerol triacetate

A technology of glycerol triacetate and glycerin, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of high energy consumption, high product color, and easy polymerization of products, and achieve Complete chemical reaction, fewer side reactions, less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

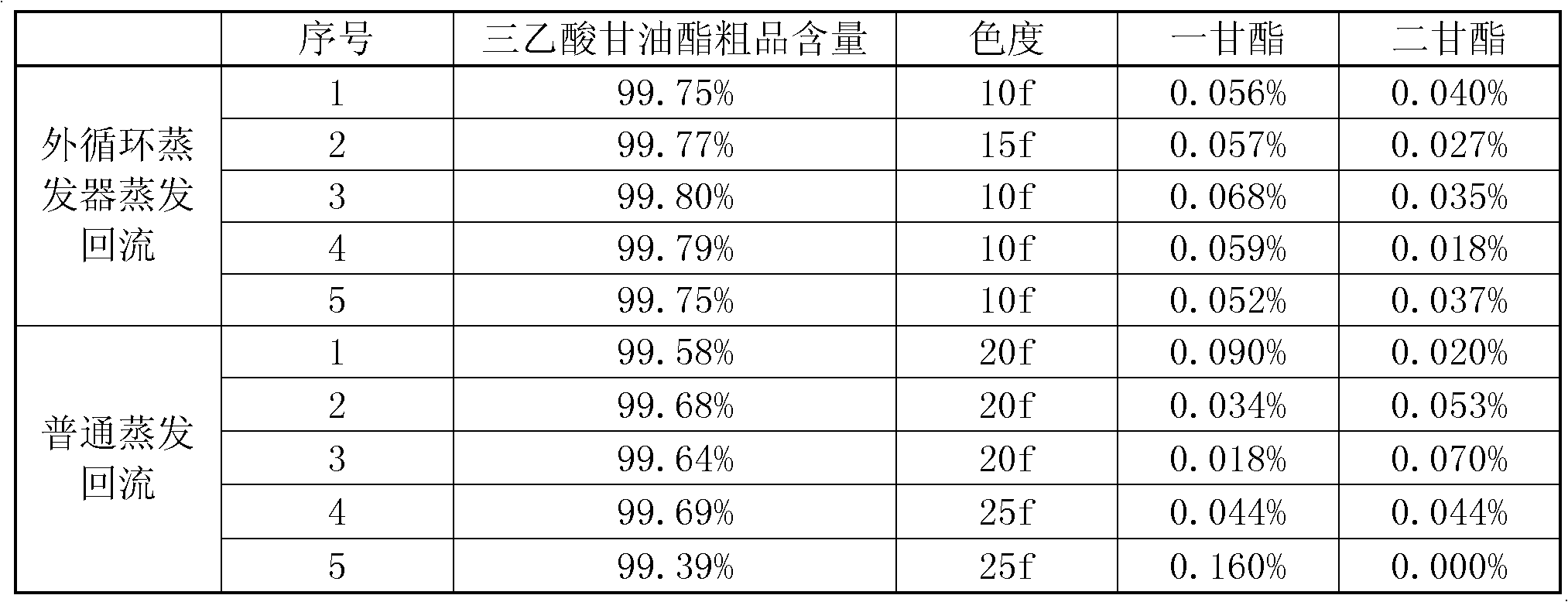

Examples

Embodiment 1

[0026] Utilizing the acid alcohol esterification reaction mechanism, the esterification reaction adopts distillation technology, adding glycerin, glacial acetic acid, acid catalyst, and azeotropic dehydrating agent to the reaction kettle with glass tower and condenser, and the mixture in the reaction kettle is passed through the pump Press into the external external circulation evaporator, control the temperature of the reaction kettle at about 100℃, and the temperature inside the external circulation evaporator at about 110℃. The water produced by the reaction is continuously discharged at the top of the tower through the external circulation evaporator, and the azeotropic agent is refluxed to the tower in. The crude product is sent to the acylation kettle, acetic anhydride is added to the reaction, and then deacidified to obtain the crude triacetin;

[0027] Put the measured crude triacetin into the refining kettle, and put into the activated carbon soaked in triacetin in advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com