Patents

Literature

53results about How to "Addressing Inadequate Contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

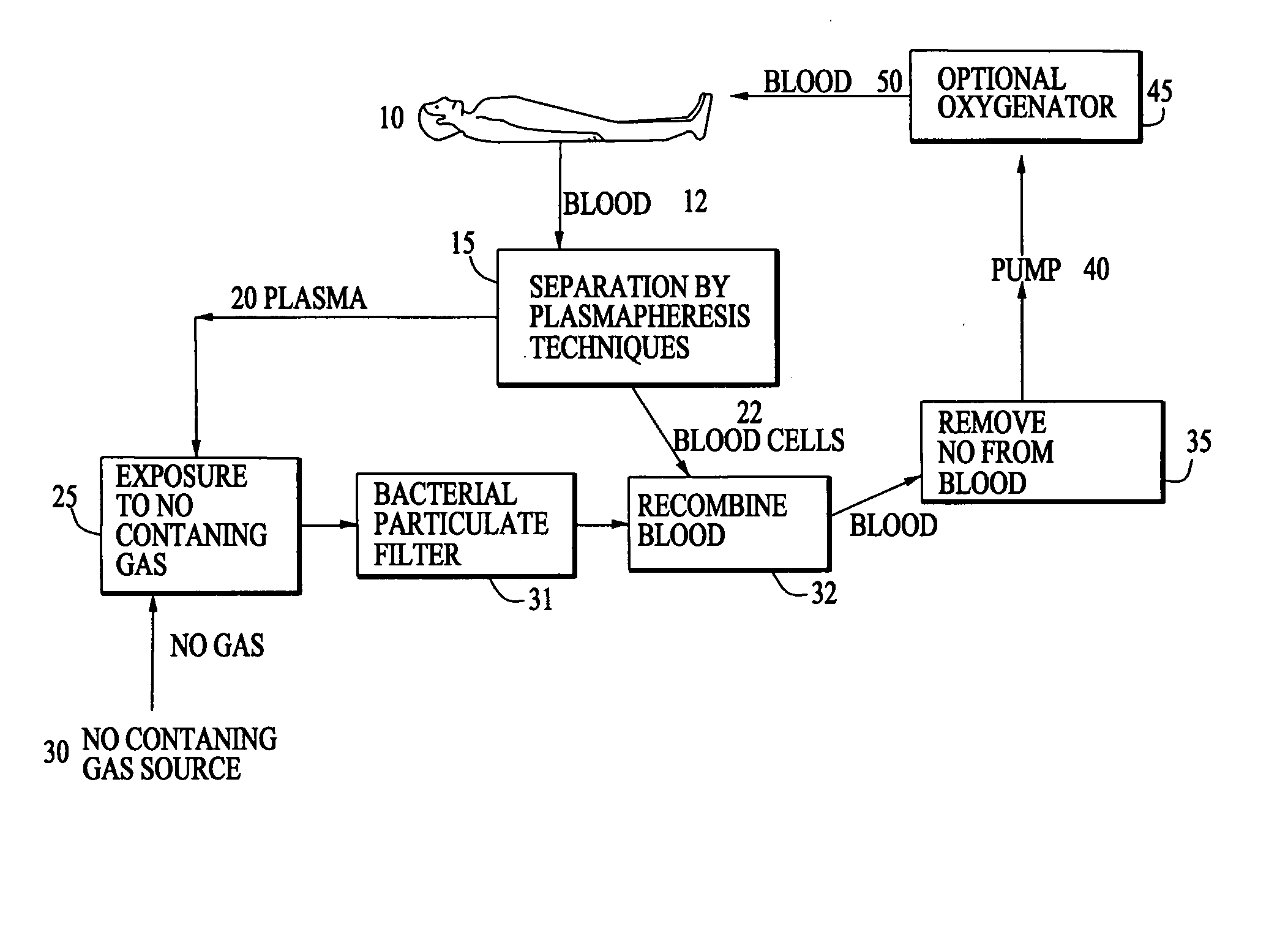

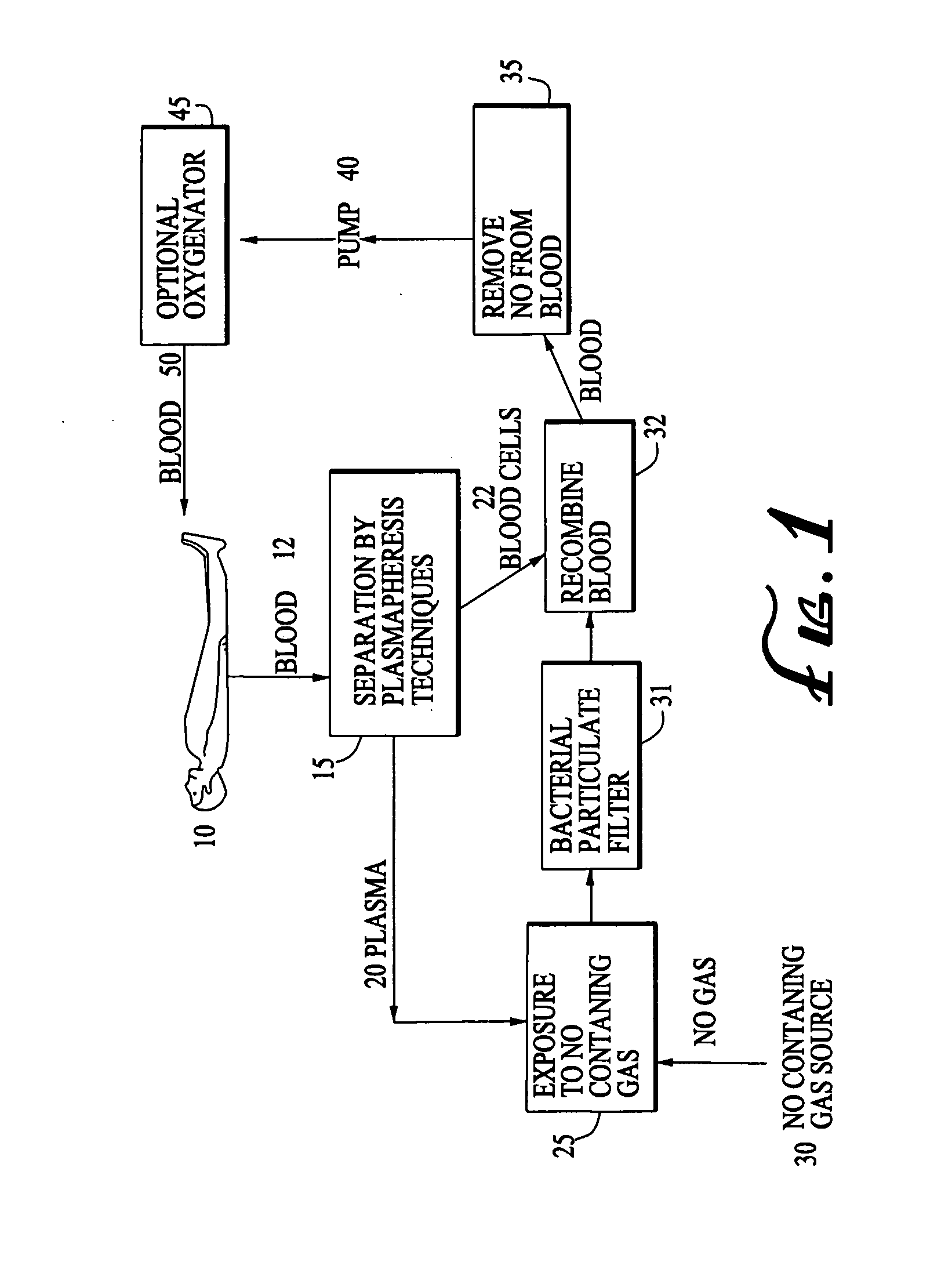

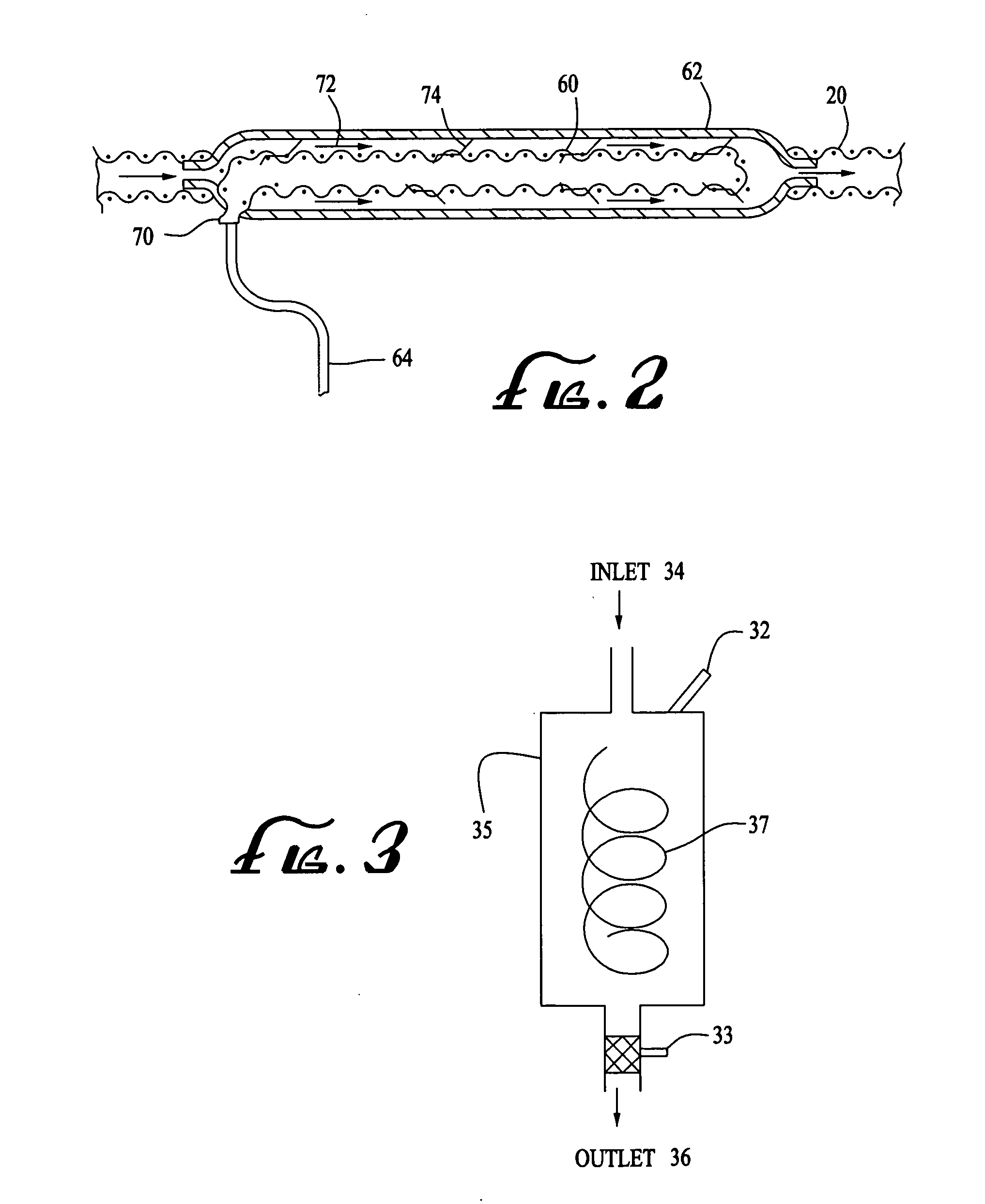

Use of nitric oxide gas in an extracorporeal circuitry to treat blood plasma

InactiveUS7531133B2Reduce pathogensReducing nitric oxide contentSemi-permeable membranesSolvent extractionPlasma exposureNitric oxide gas

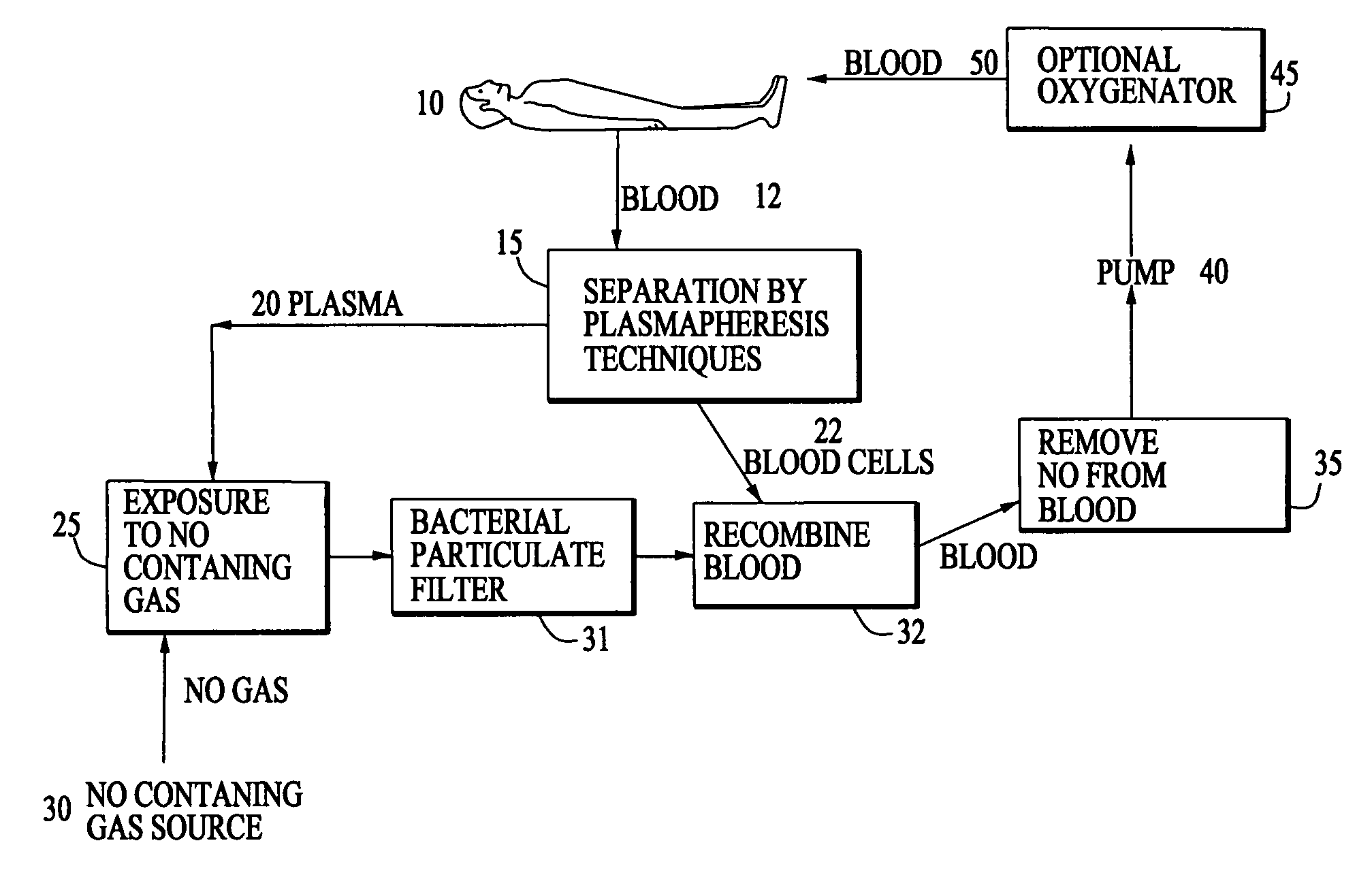

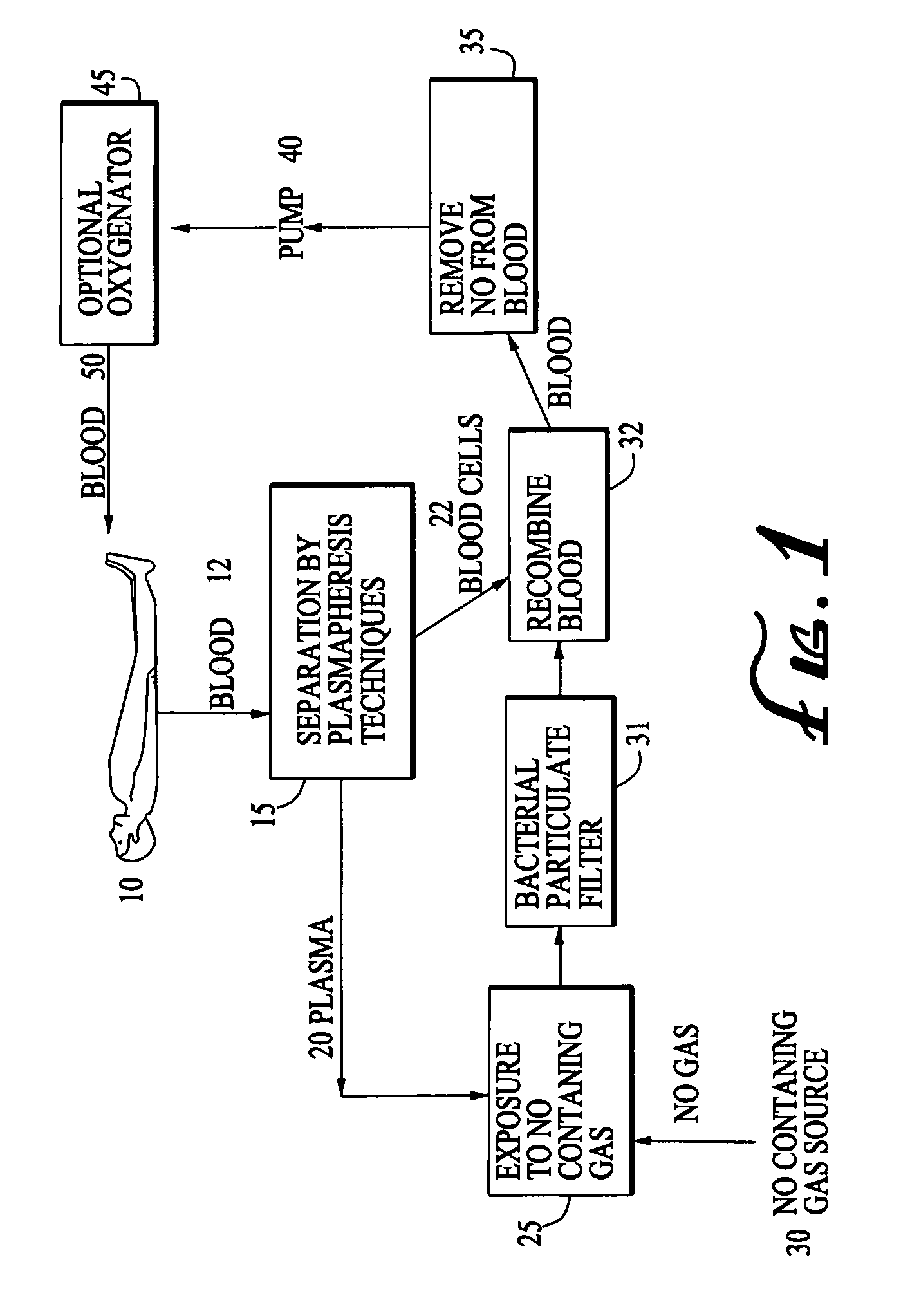

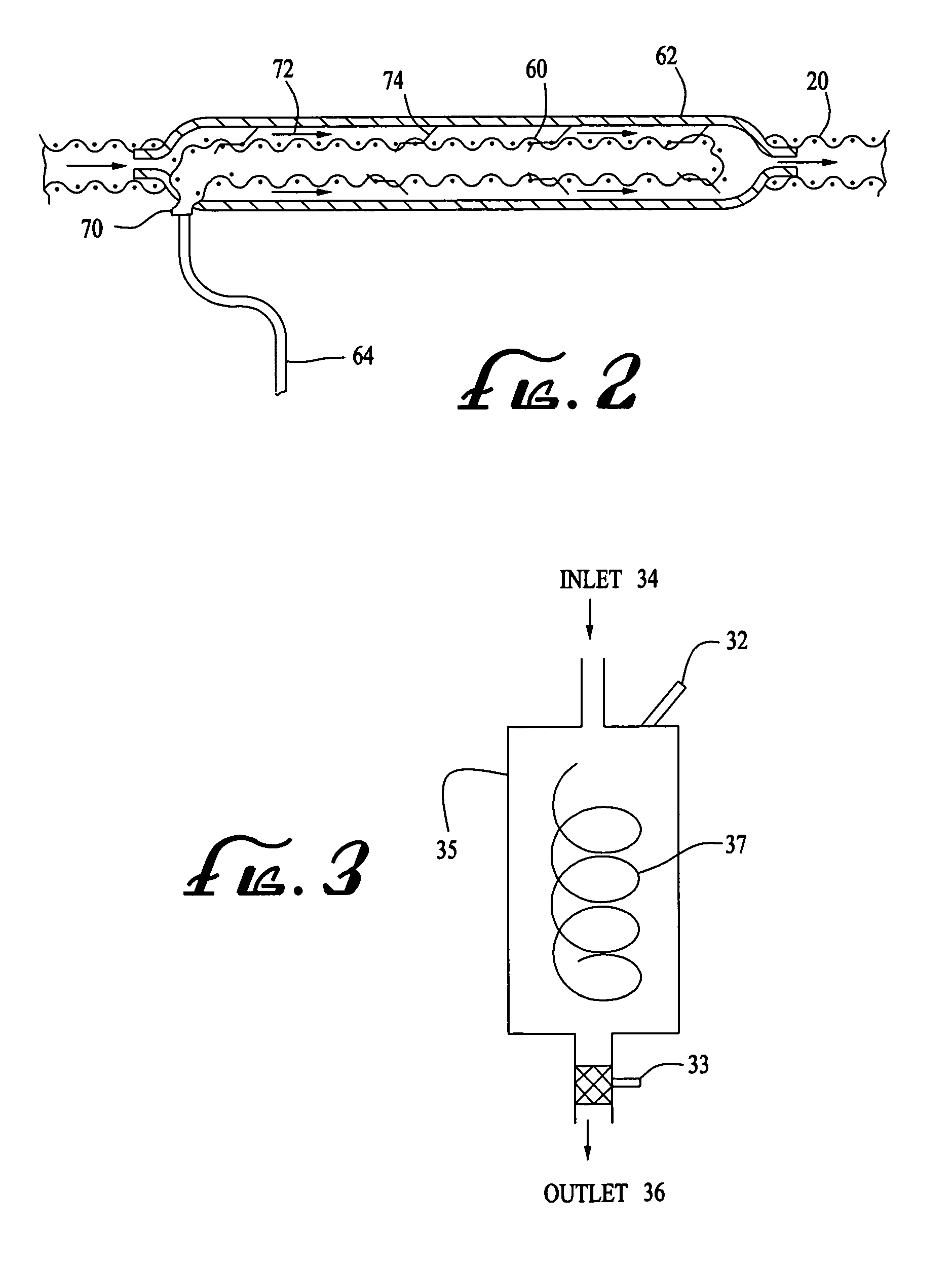

A method of reducing pathogens in blood by exposure to a nitric oxide containing gas in an extracorporeal circuitry is provided. The method includes: obtaining blood from a mammal or a blood source, separating the blood into plasma and blood cells, exposing the plasma to nitric oxide containing gas, combining the exposed plasma with the blood cells, reducing nitric oxide content in the recombined blood, and returning the blood to the mammal or blood source.

Owner:ADVANCED INHILATION THERAPIES AIT LTD

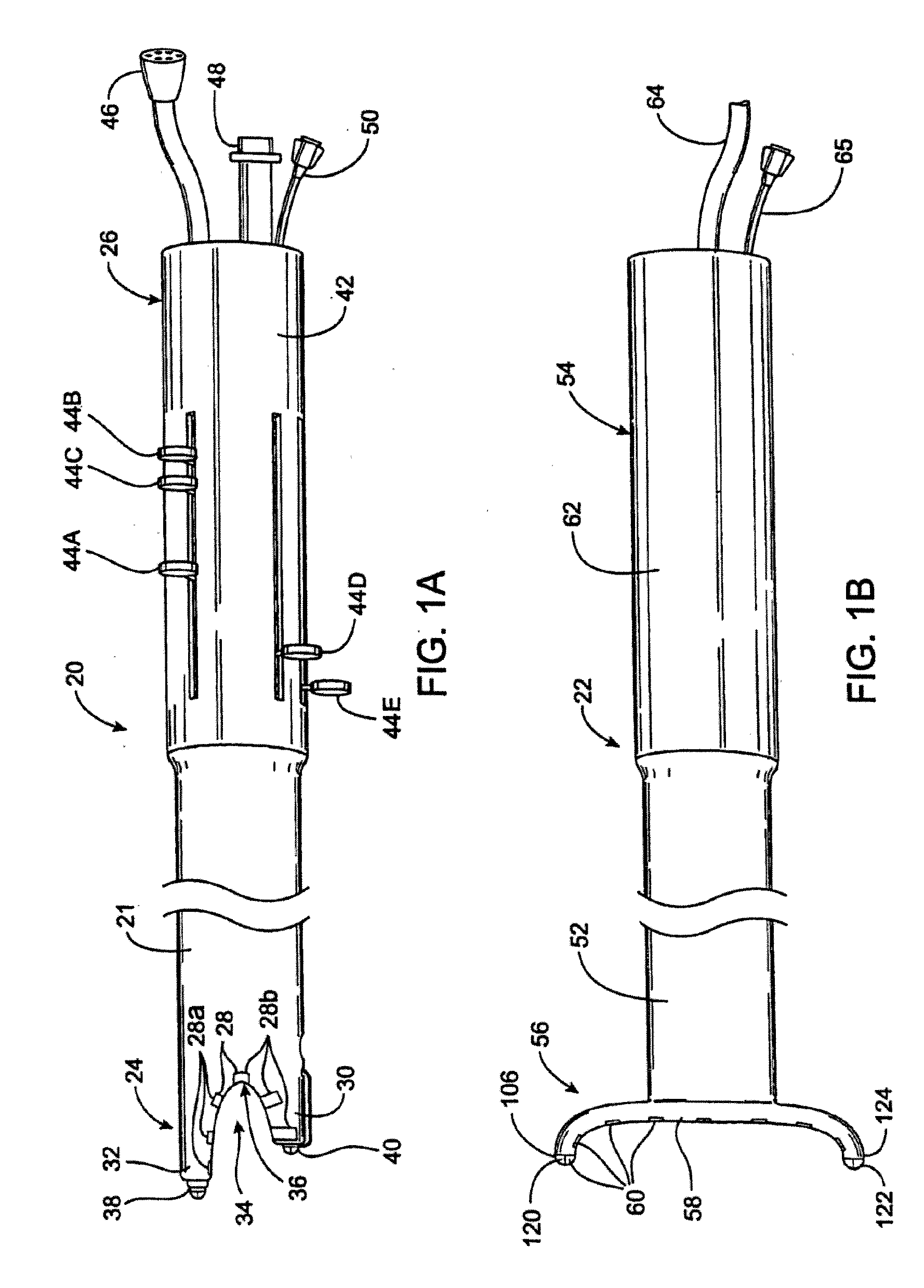

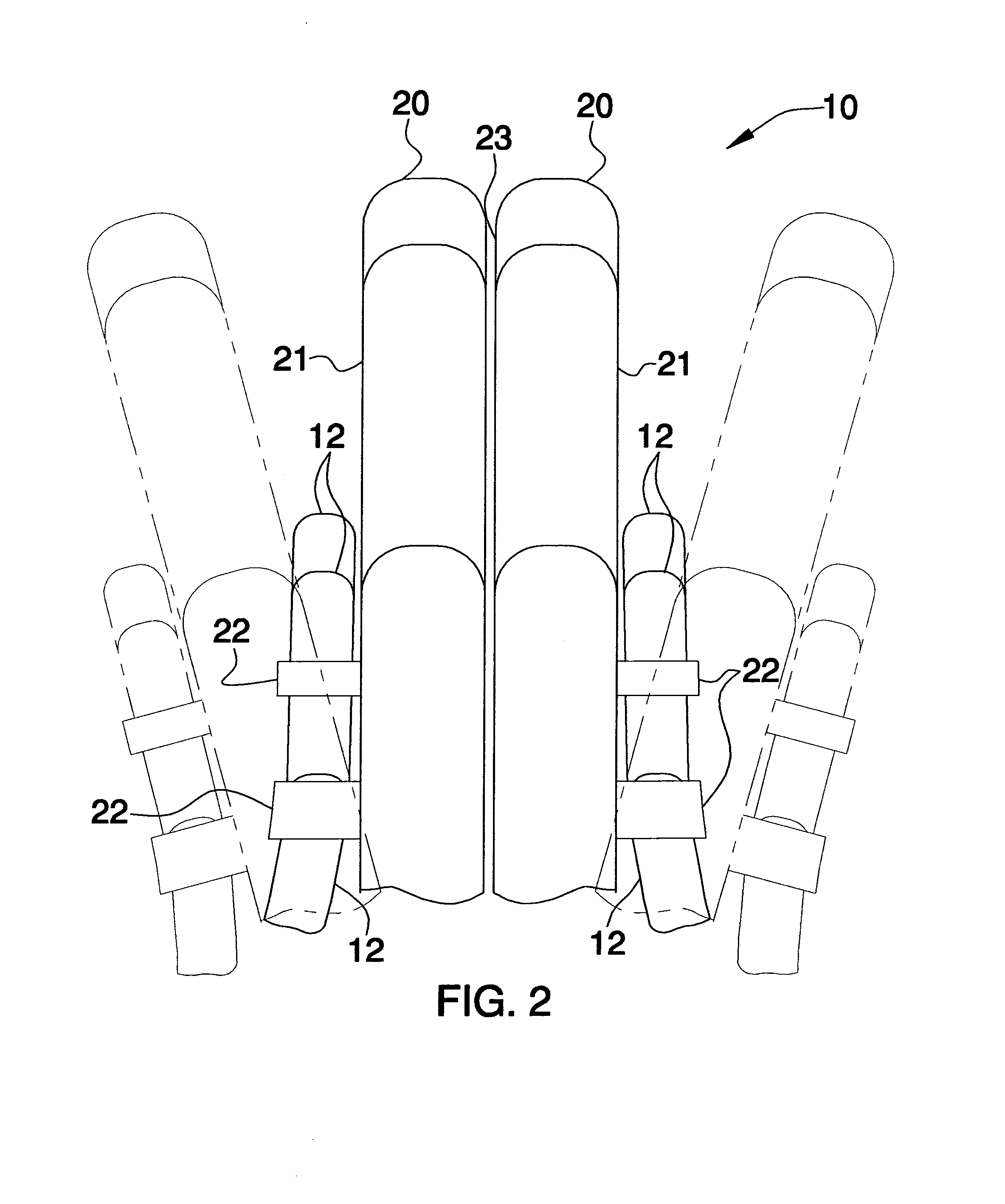

Devices and methods for ablating cardiac tissue

InactiveUS20080045946A1Improve visualizationQuick to useUltrasound therapyElectrocardiographyBiomedical engineeringLesion

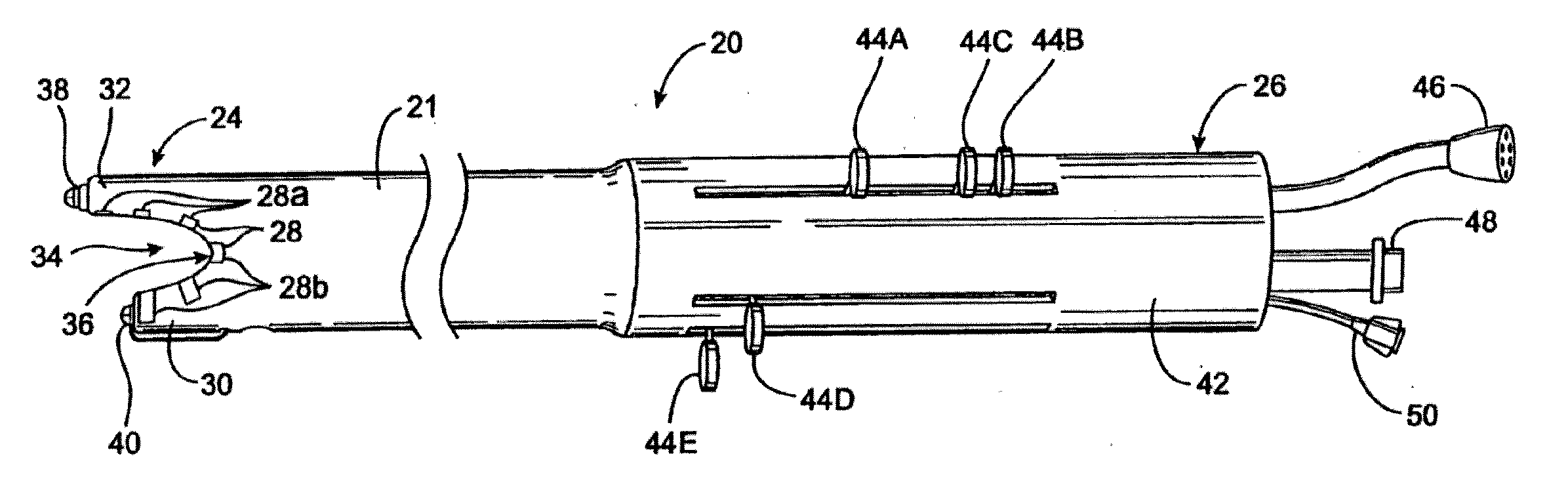

An ablation device for ablating epicardial tissue on a heart is disclosed. The device includes an elongated probe having at least one tissue contacting surface for contacting the epicardial tissue. The device also includes a plurality of suction ports and a plurality of ablating elements aligned along at least part of the axis of the elongated probe and coupled with a tissue contacting member. The assembly may optionally include a visualization device to determine the location and depth of transmural lesions. Also disclosed are methods of locating and placing the ablation device and forming transmural lesions on a heart for treatment of cardiac arrythmias.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

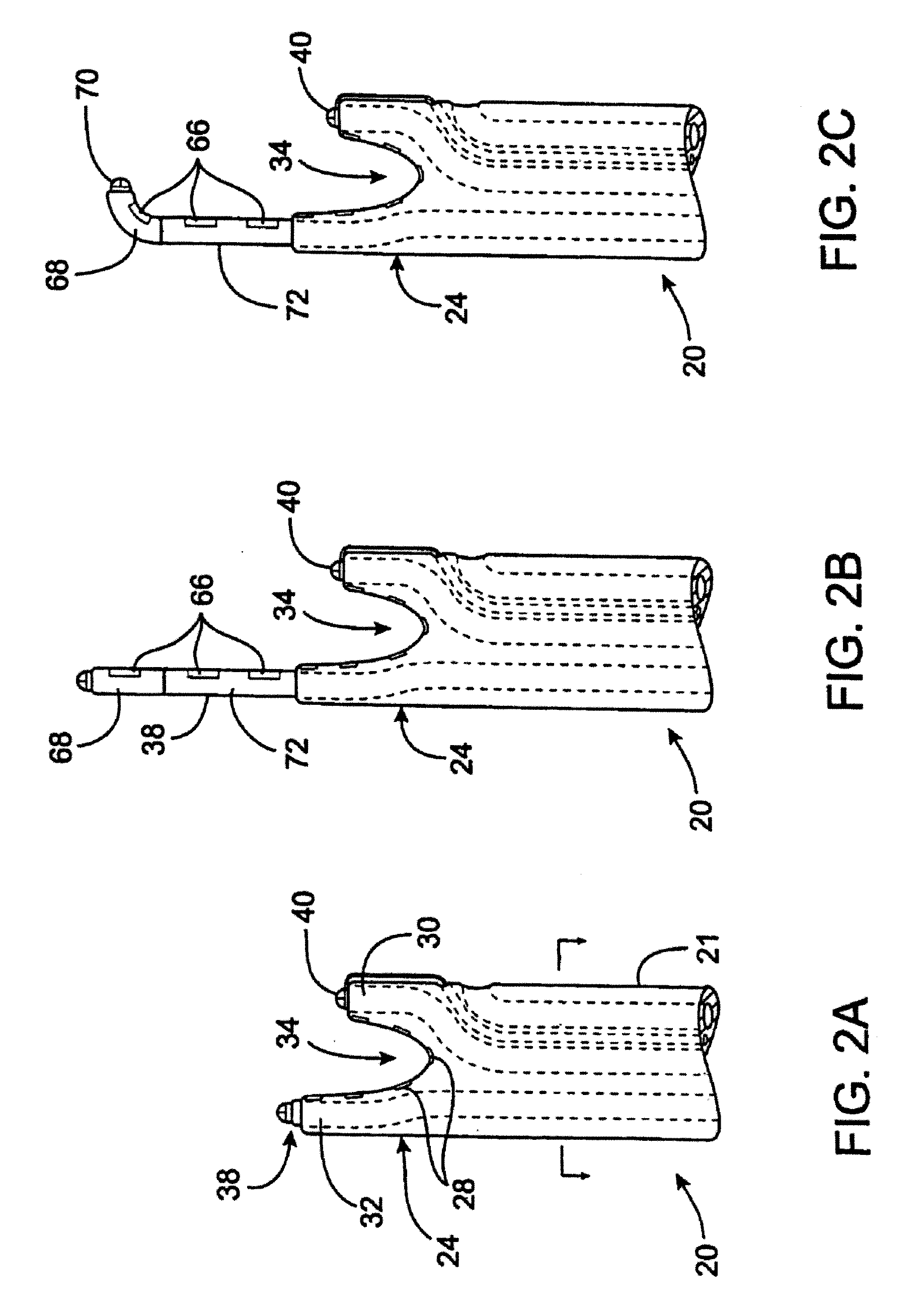

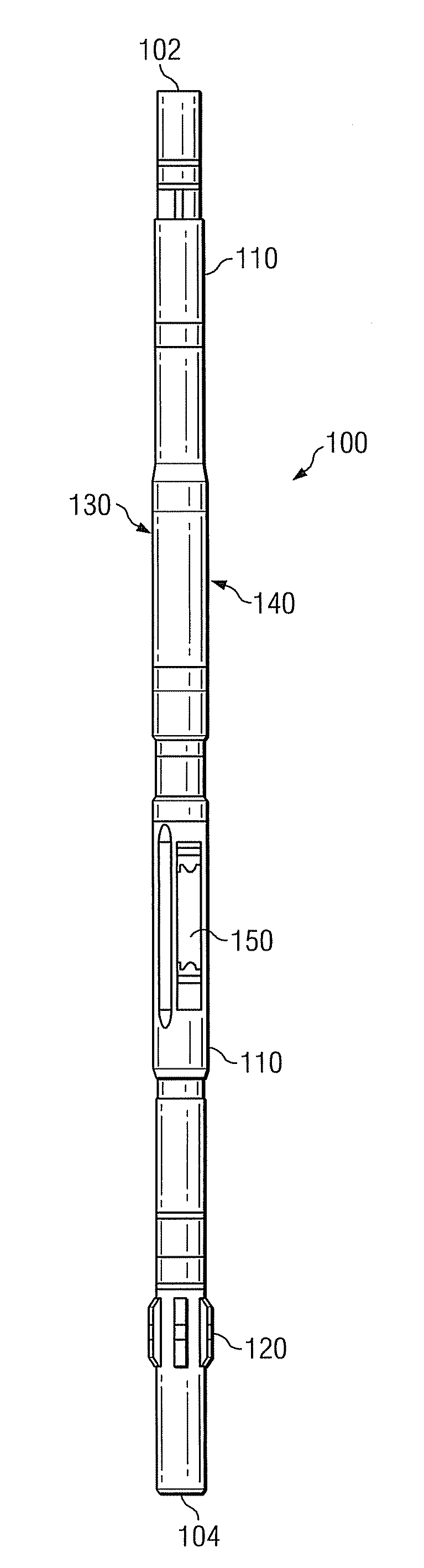

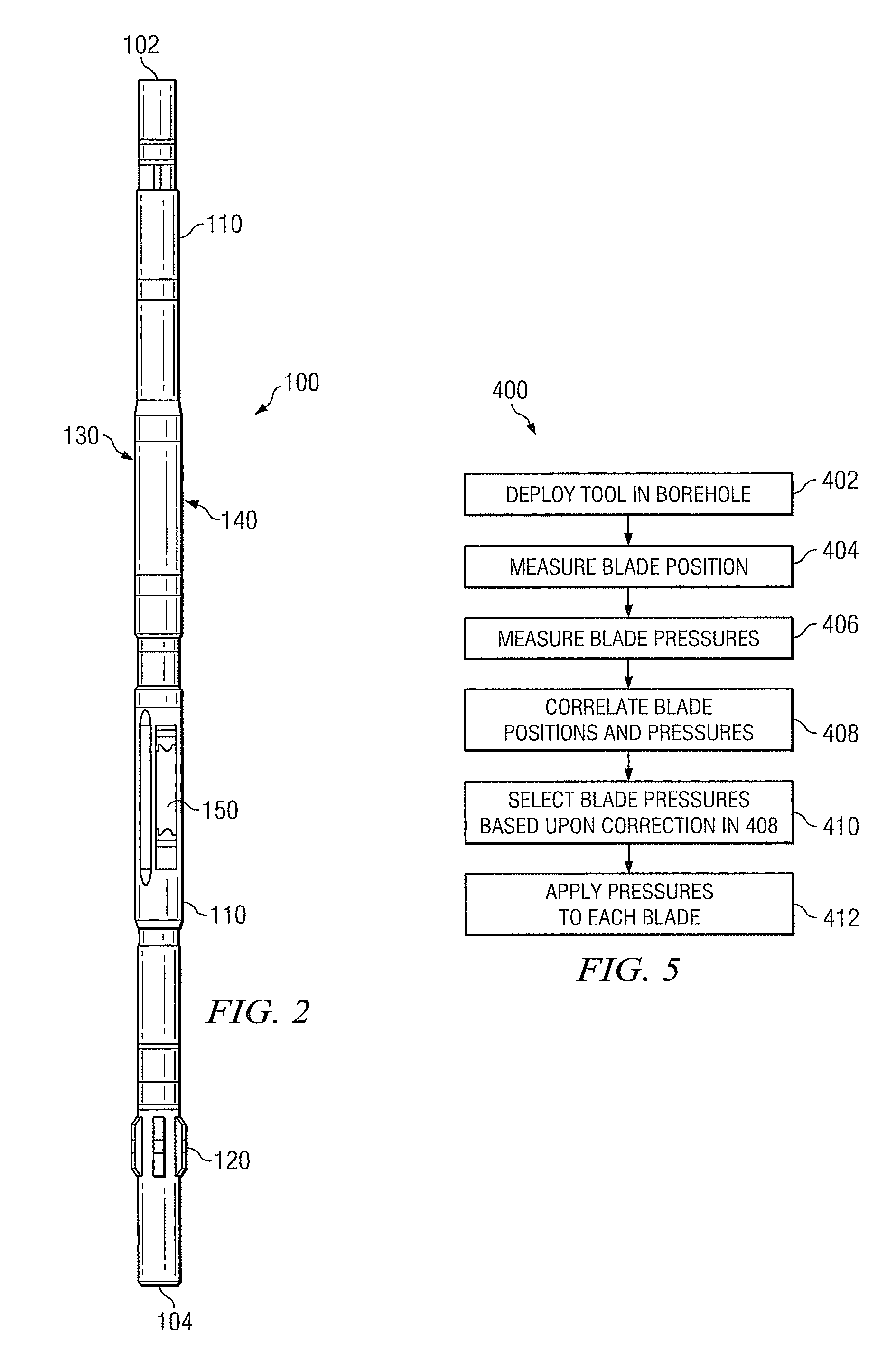

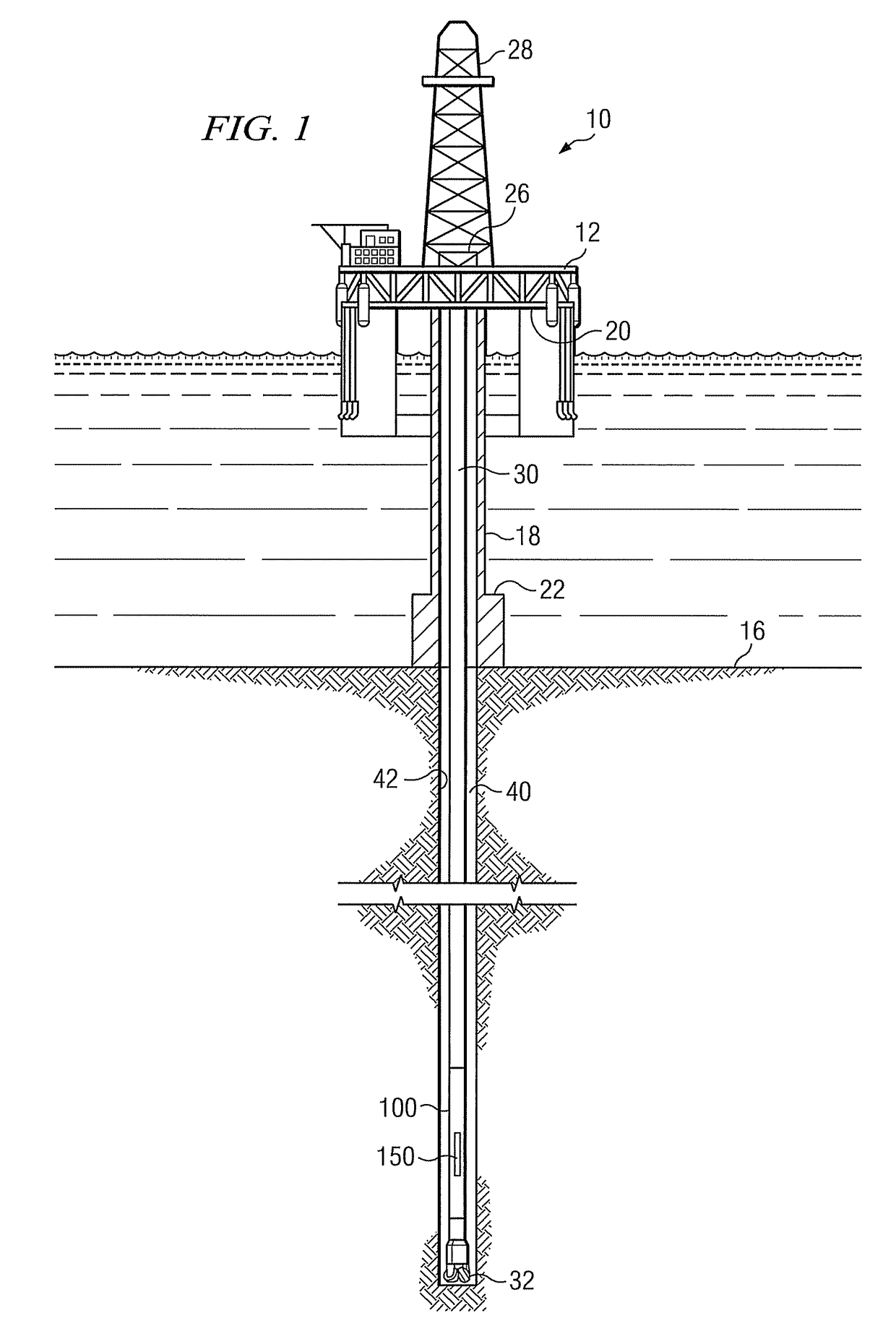

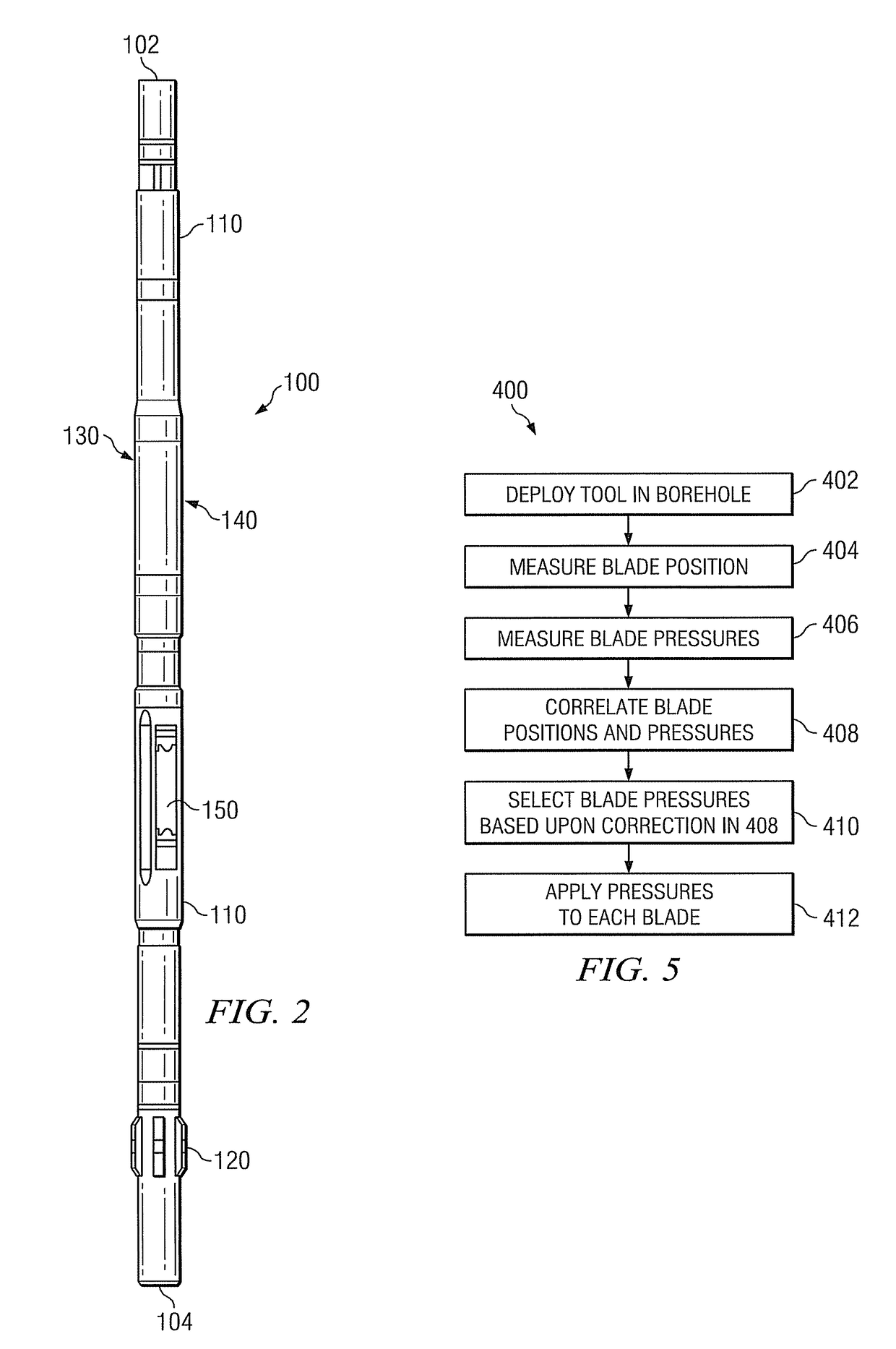

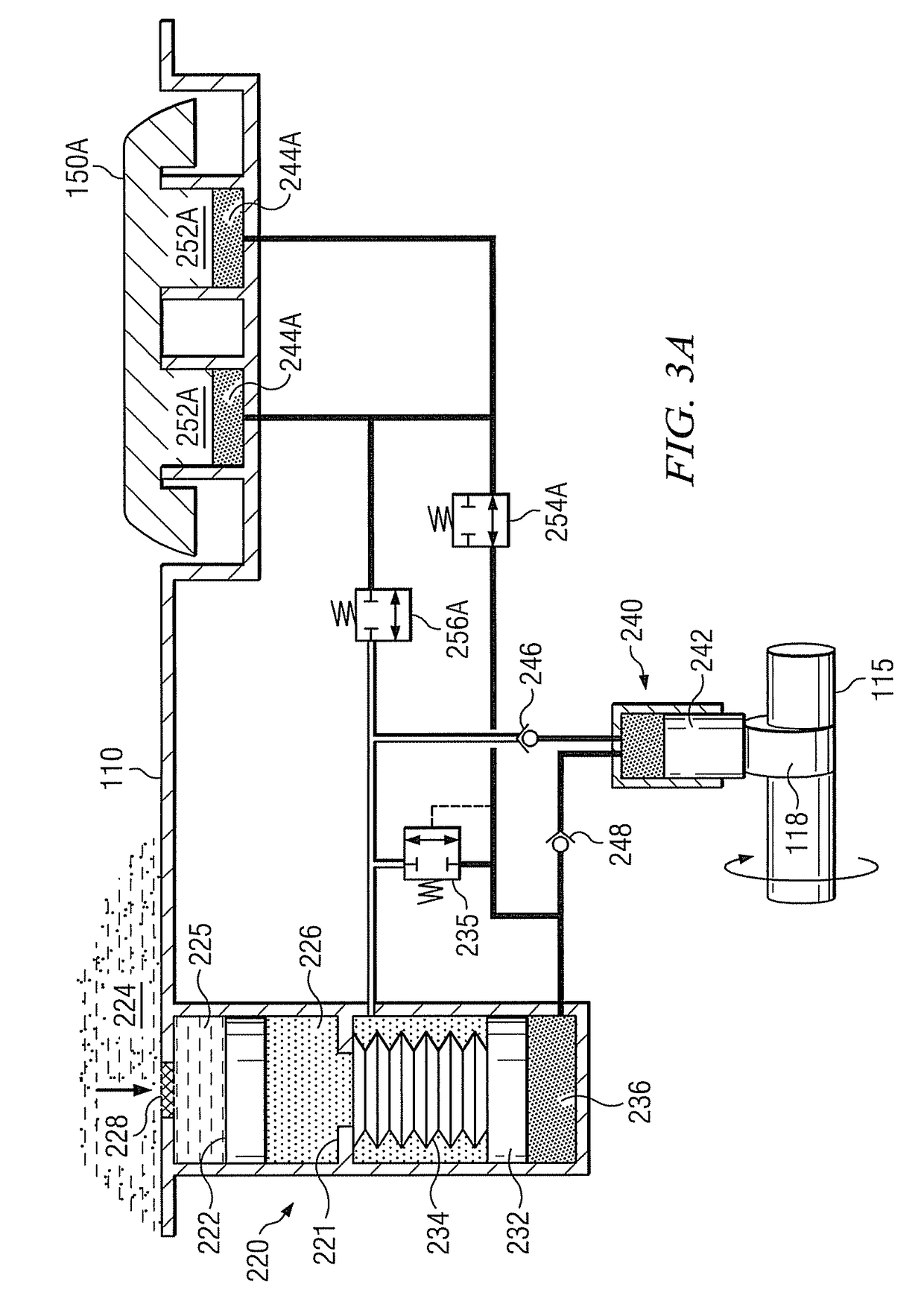

Closed-Loop Control of Rotary Steerable Blades

InactiveUS20090166086A1Reduce housing rollPromote accurate borehole caliper measurementSurveyFlushingClosed loopPressure measurement

A steering tool has a controller configured to provide closed-loop control of blade pressure and position. In one embodiment, the controller is configured to execute a directional control methodology in which the drilling direction is controlled via control of the blade position. The pressure in each blade is further controlled within a predetermined range of pressures. This embodiment tends to prevent excessive borehole friction while at the same time reducing undesirable rotation of the blade housing. In another embodiment, the controller is configured to correlate blade pressure measurements and blade position measurements during drilling. The correlation is utilized as part of a secondary directional control scheme in the event of a downhole failure of a blade position and / or pressure sensor. This embodiment tends to provide a stable and reliable backup directional control mechanism in the event a sensor failure and therefore may save considerable rig time.

Owner:SCHLUMBERGER TECH CORP

Use of nitric oxide gas in an extracorporeal circuitry to treat blood plasma

InactiveUS20070014688A1Reduce pathogensLow oxide contentSemi-permeable membranesSolvent extractionNitric oxide gasBlood plasma

A method of reducing pathogens in blood by exposure to a nitric oxide containing gas in an extracorporeal circuitry is provided. The method includes: obtaining blood from a mammal or a blood source, separating the blood into plasma and blood cells, exposing the plasma to nitric oxide containing gas, combining the exposed plasma with the blood cells, reducing nitric oxide content in the recombined blood, and returning the blood to the mammal or blood source.

Owner:ADVANCED INHILATION THERAPIES AIT LTD

Separator for a fuel cell

InactiveUS6468685B1Improve flatnessAddressing Inadequate ContactCell seperators/membranes/diaphragms/spacersFinal product manufactureFuel cellsShell molding

In a separator for a fuel cell according to the invention, a separator is formed by a molding a bondcarbon compound in which a composition ratio of graphite powder is set to 60 to 90%, and a composition ratio of a thermosetting resin is set to 10 to 40%, and at least a top end face of each of a number of ribs contacting the surface of an anode or a cathode is coated with a conductive film made of a material which is lower in specific resistance than the bondcarbon compound. According to this configuration, while excellent moldability and high productivity are ensured by the use of the bondcarbon compound containing a larger content of a resin, the contact resistance with respect to an electrode is lowered so that the conductivity of the whole can be improved, and predetermined performance of a fuel cell can be surely exerted.

Owner:NIPPON PILLAR PACKING CO LTD

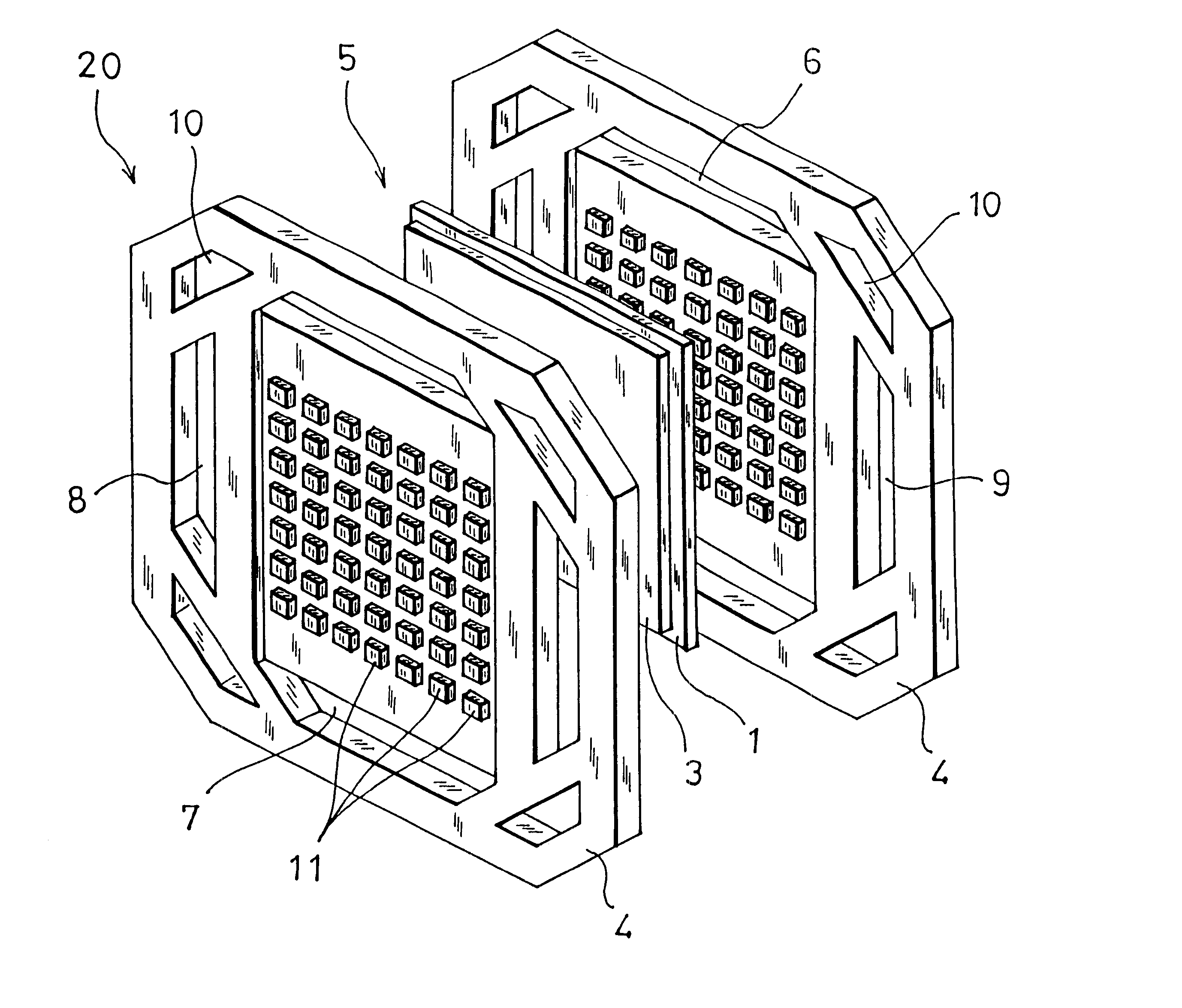

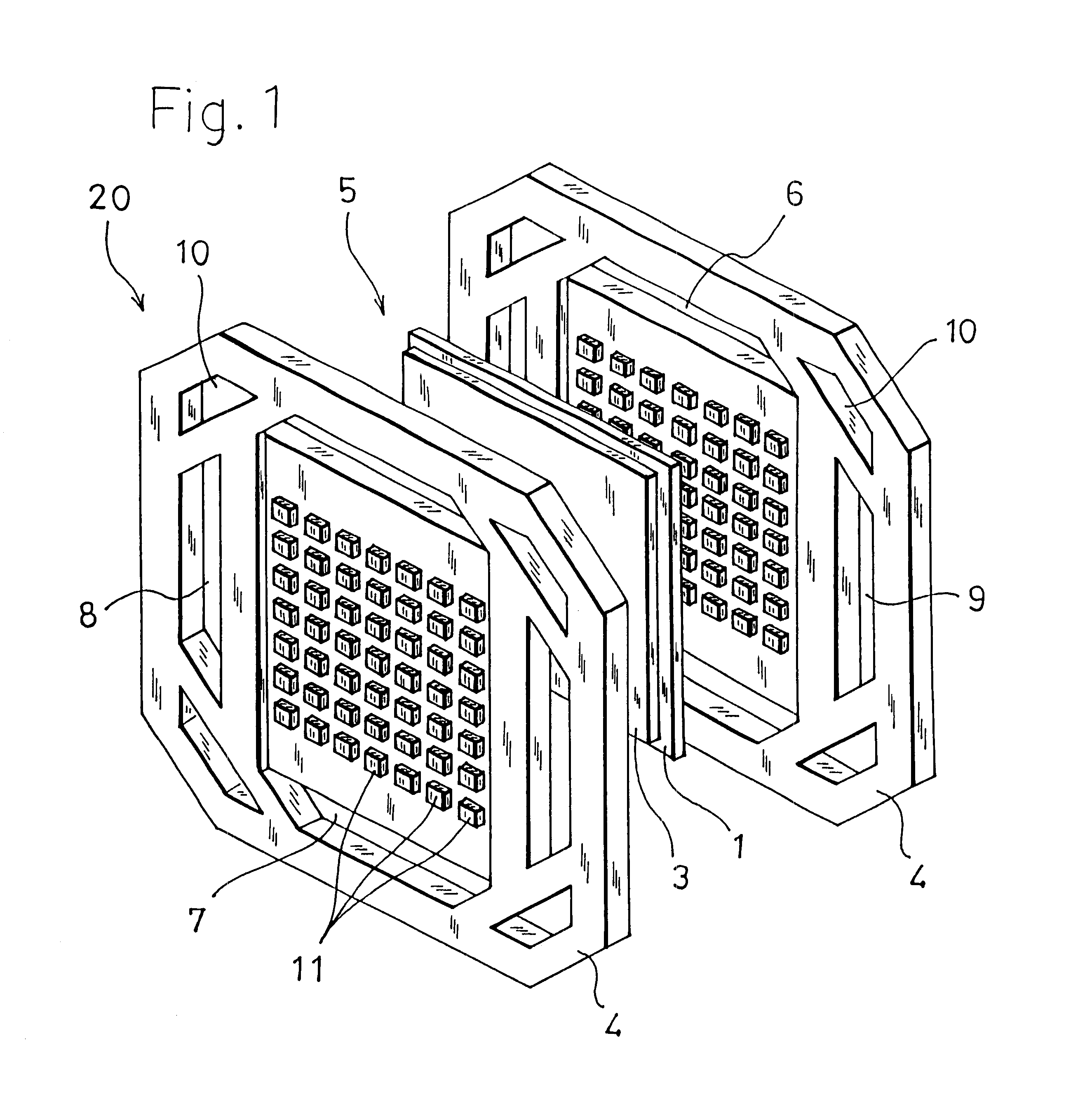

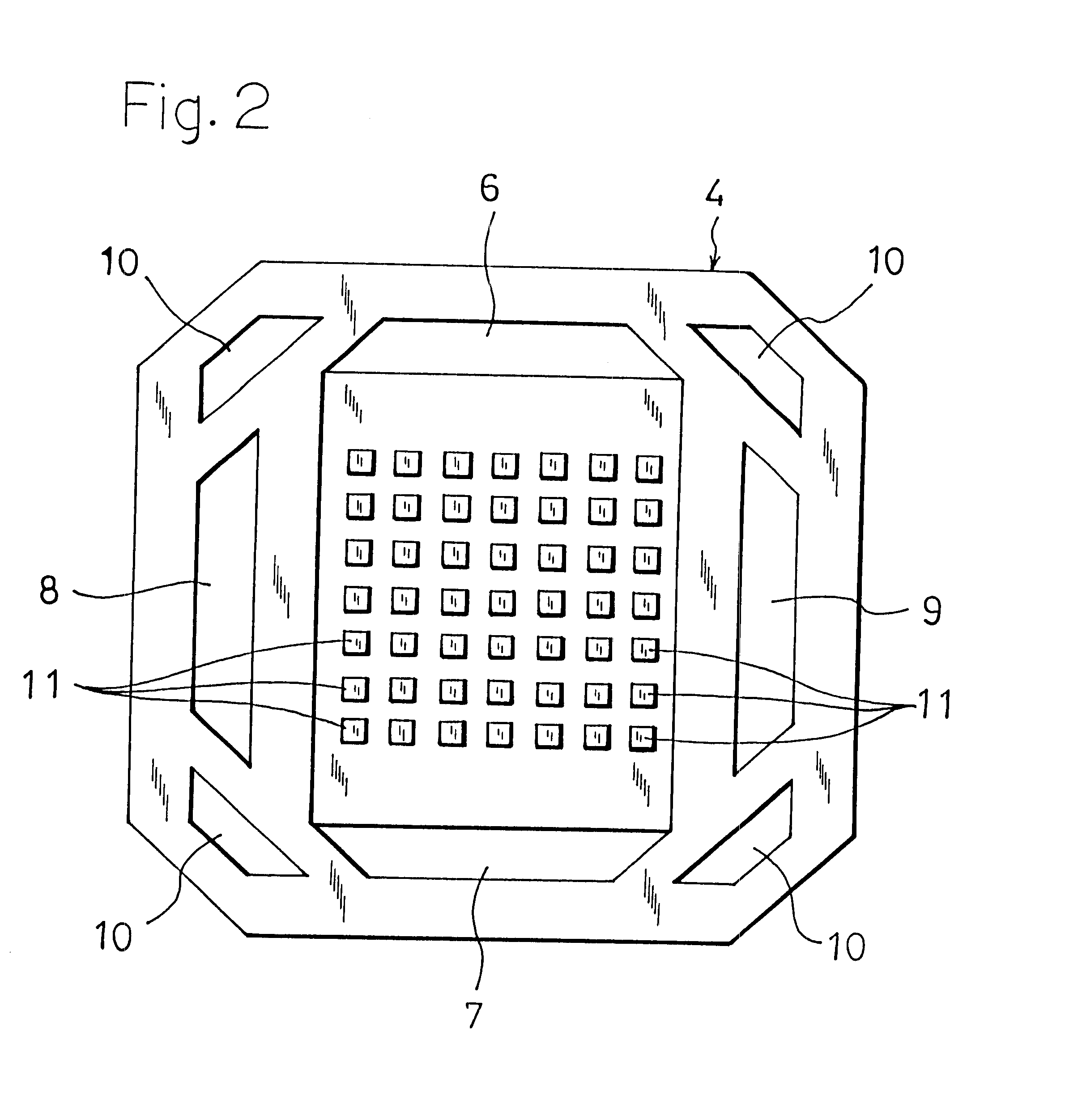

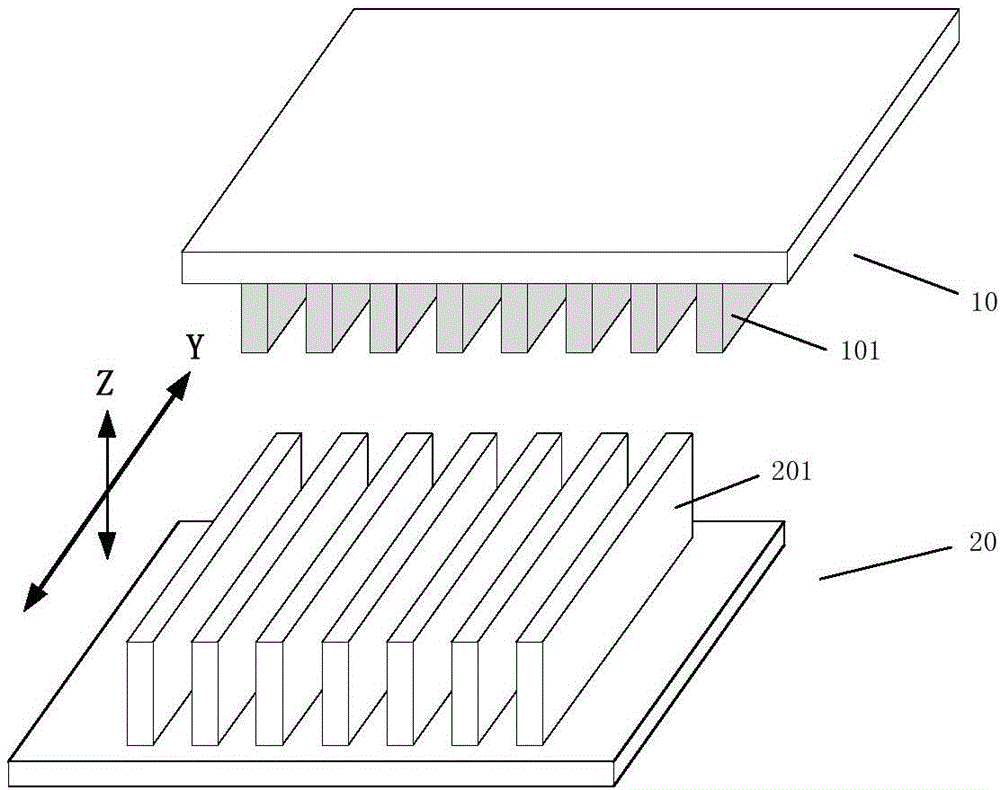

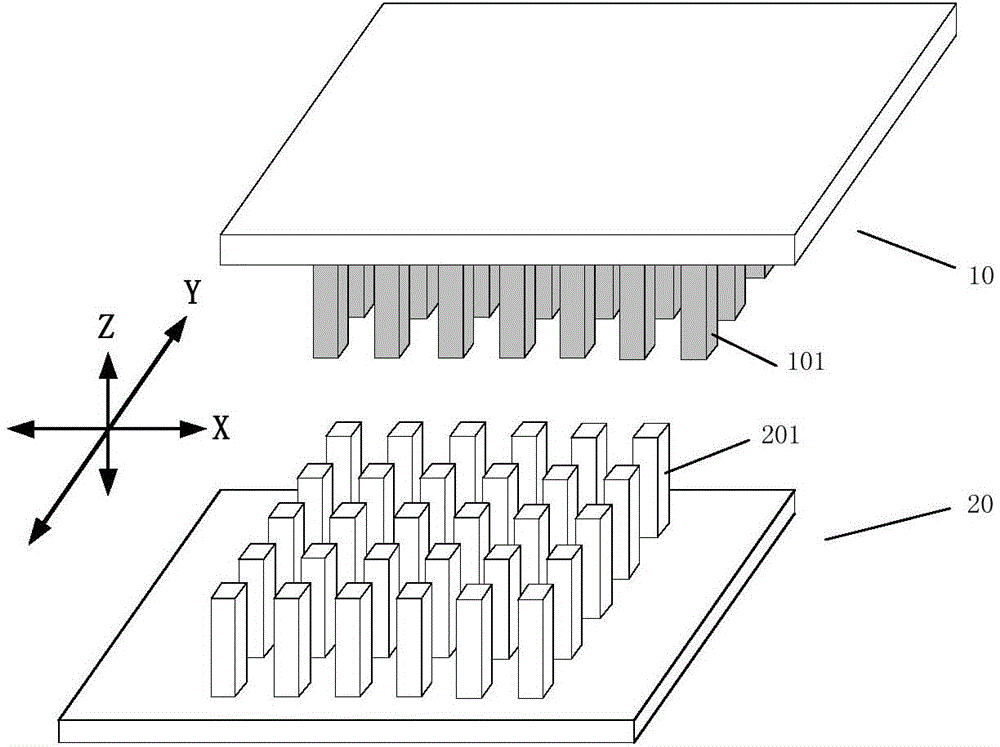

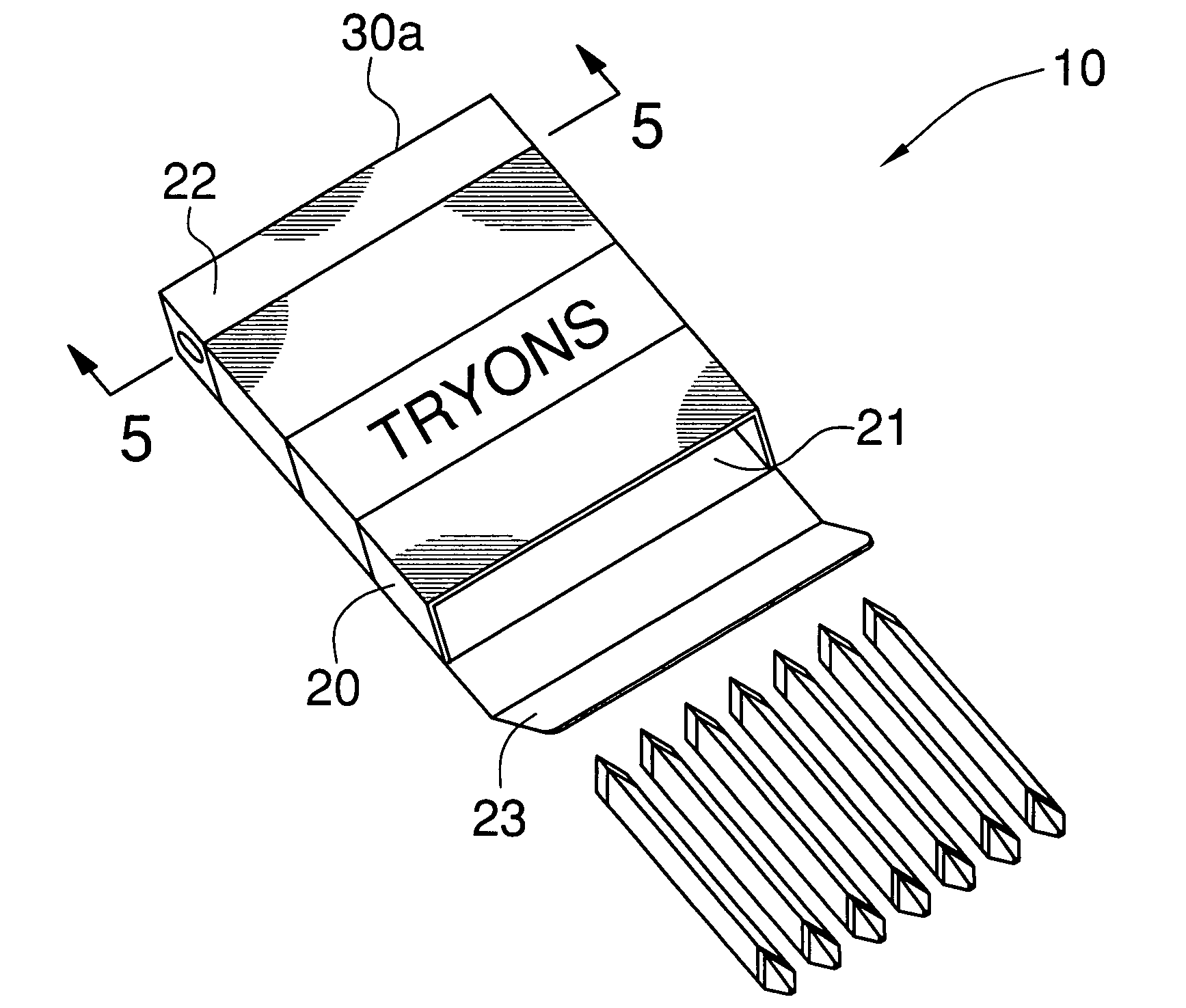

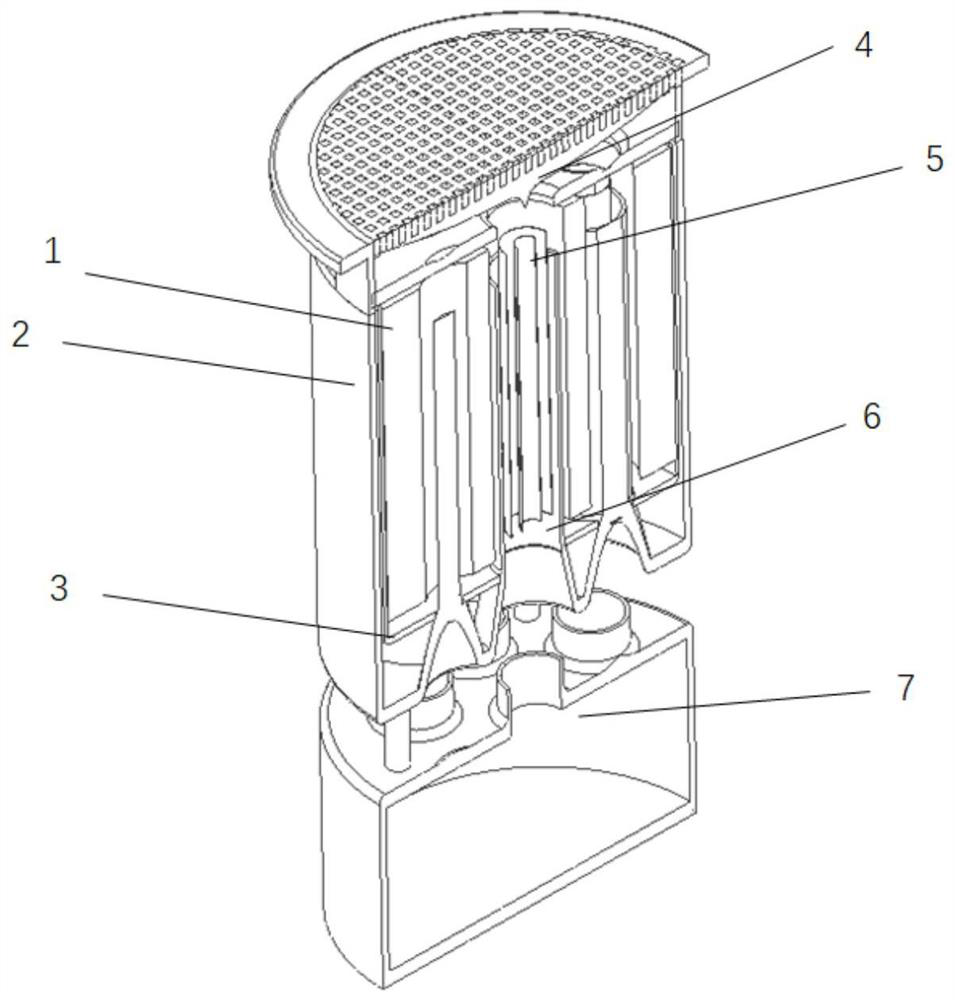

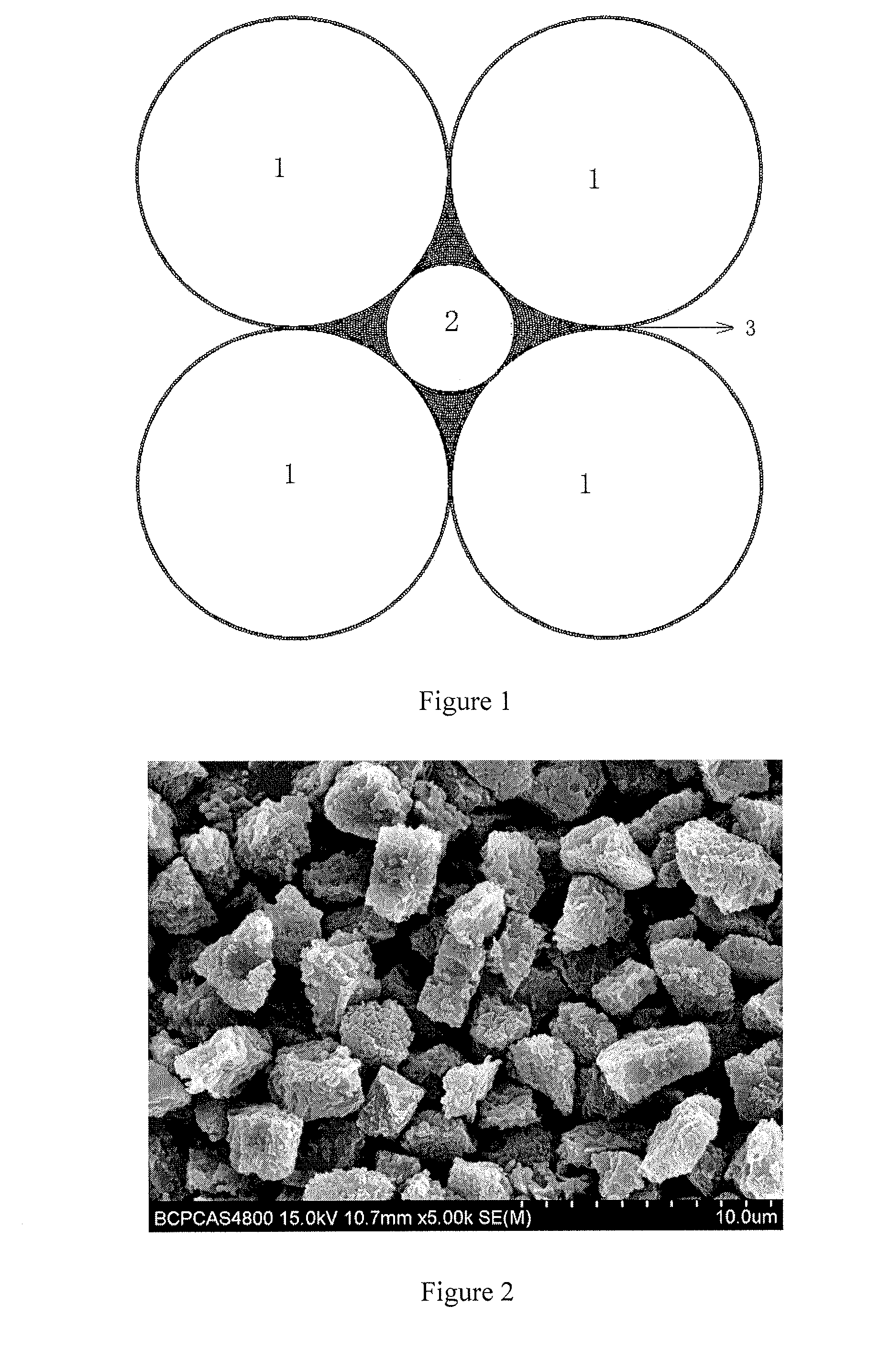

Friction nanometer power generator with gear shaping structure

ActiveCN104426420AImprove output performanceIncrease friction areaFriction generatorsGeneration processElectricity

The invention discloses a friction nanometer power generator with a gear shaping structure. The power generator mainly comprises two friction components which are connected through an elastic component, wherein at least one component is of the gear shaping structure which is formed by arranging a plurality of friction units; the gear shaping structure can form a tight occluding state with a friction unit on the other component; under the action of the elastic components, the relative position between the two components can be periodically changed by external force, so that a friction power generation process is promoted, and an electrical signal can be output outwards by the power generator. Effective extraction of vibration energy by sliding friction is realized for the first time through cooperation between the two friction units and the elastic components; meanwhile, through the occluding between first friction units and second friction units matched with the first friction units which are distributed in a gear shaping state, the area of sliding friction is increased, and the electricity output performance of the power generator is improved.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Closed-loop control of rotary steerable blades

InactiveUS8118114B2Reduce frictionAccurate measurementSurveyDirectional drillingLoop controlWell drilling

A steering tool has a controller configured to provide closed-loop control of blade pressure and position. In one embodiment, the controller is configured to execute a directional control methodology in which the drilling direction is controlled via control of the blade position. The pressure in each blade is further controlled within a predetermined range of pressures. This embodiment tends to prevent excessive borehole friction while at the same time reducing undesirable rotation of the blade housing. In another embodiment, the controller is configured to correlate blade pressure measurements and blade position measurements during drilling. The correlation is utilized as part of a secondary directional control scheme in the event of a downhole failure of a blade position and / or pressure sensor.

Owner:SCHLUMBERGER TECH CORP

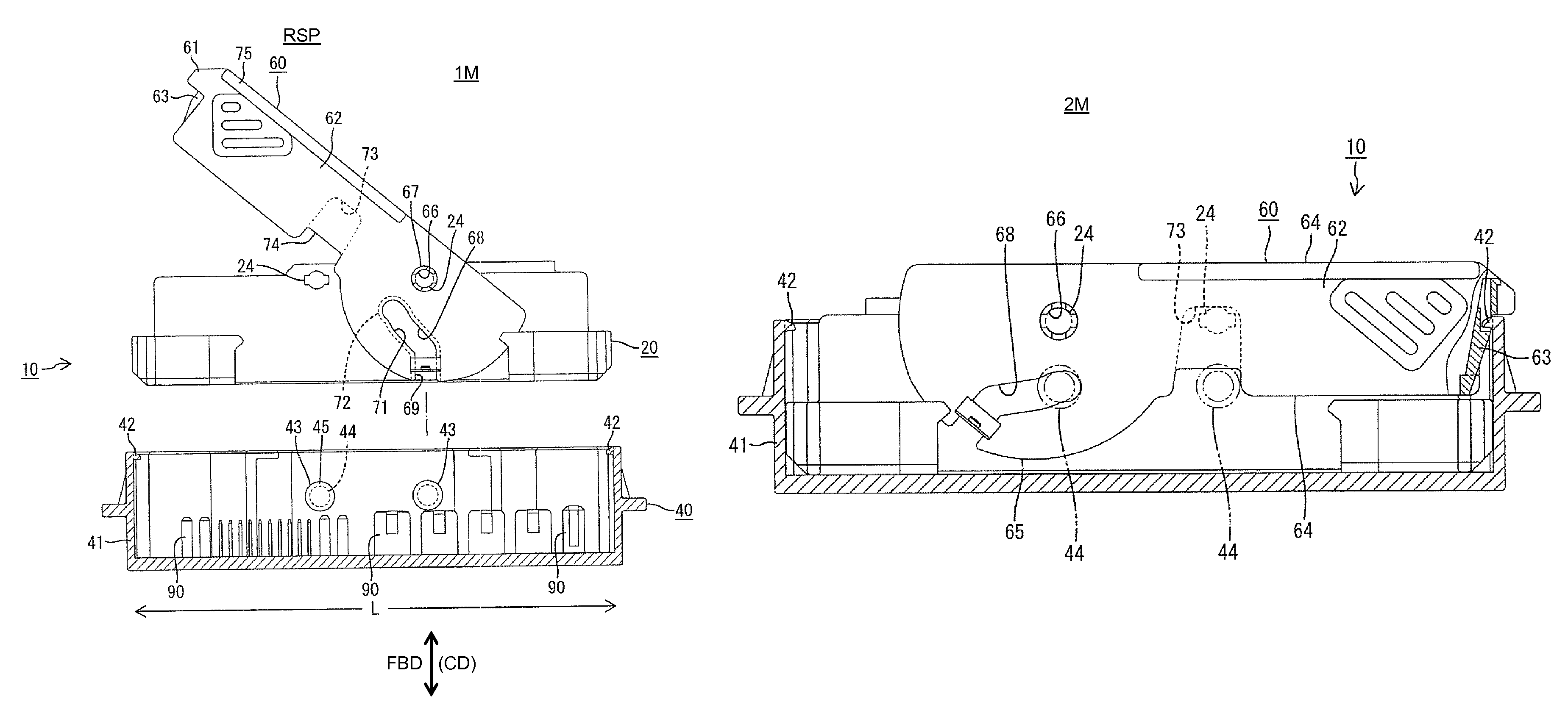

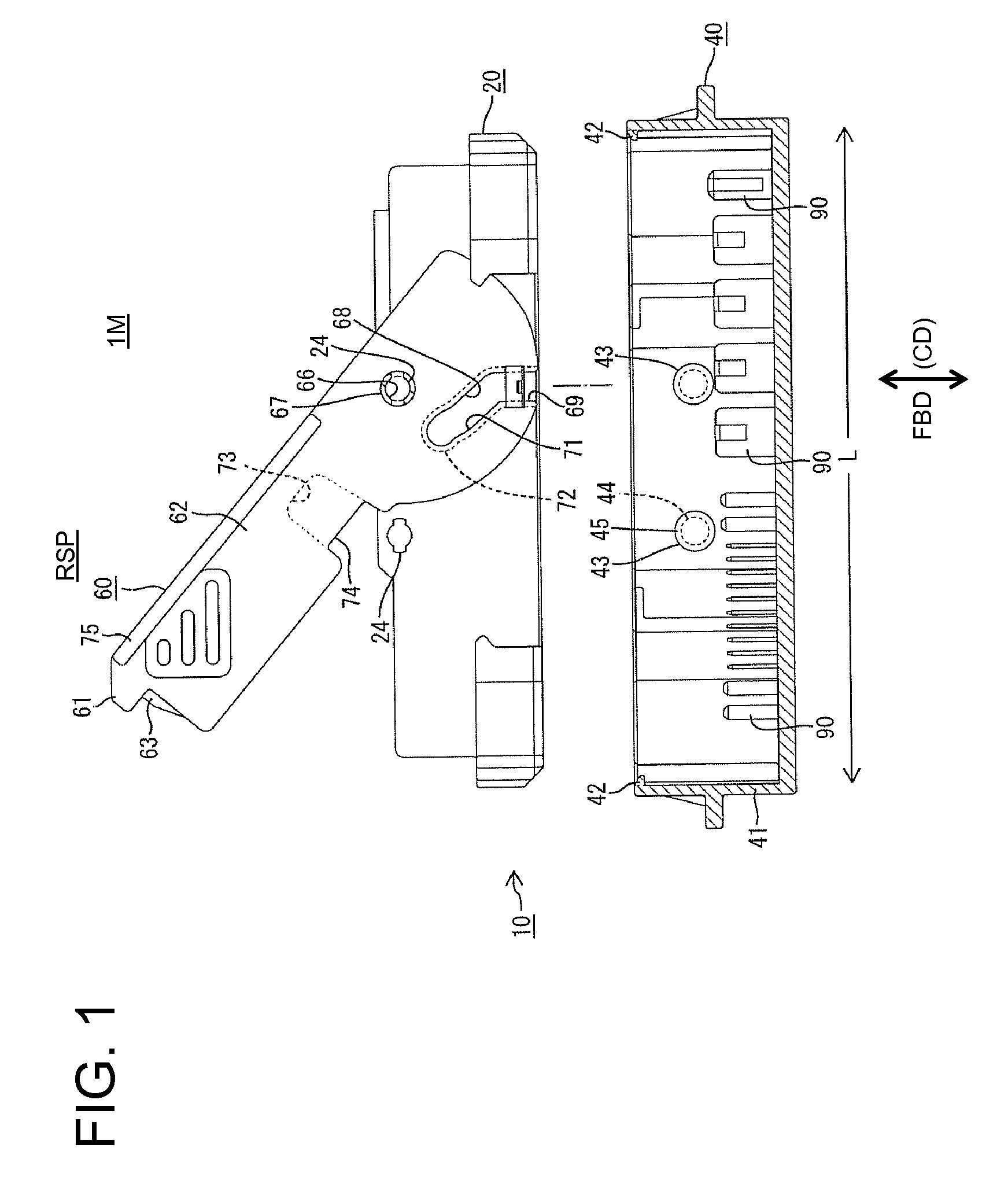

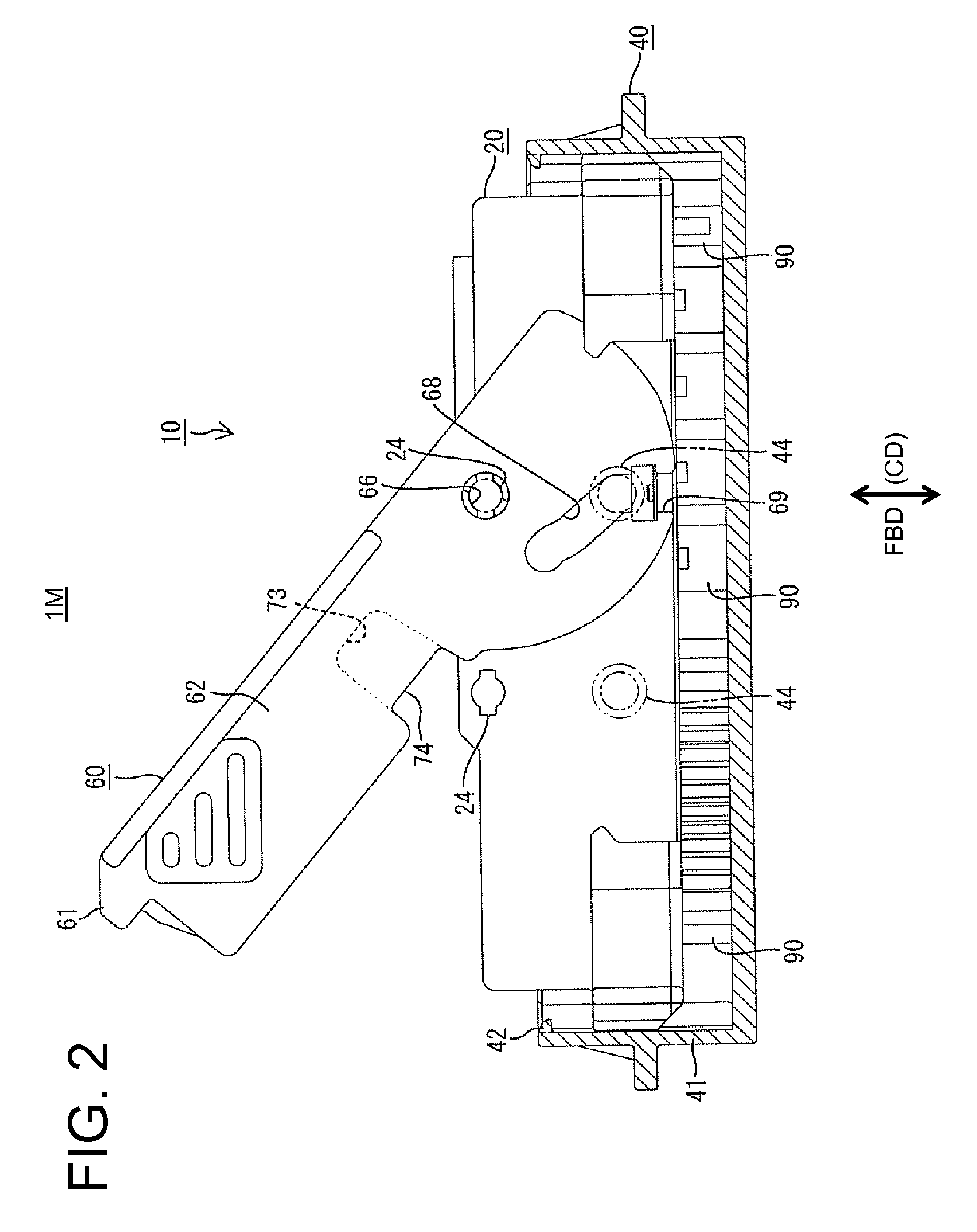

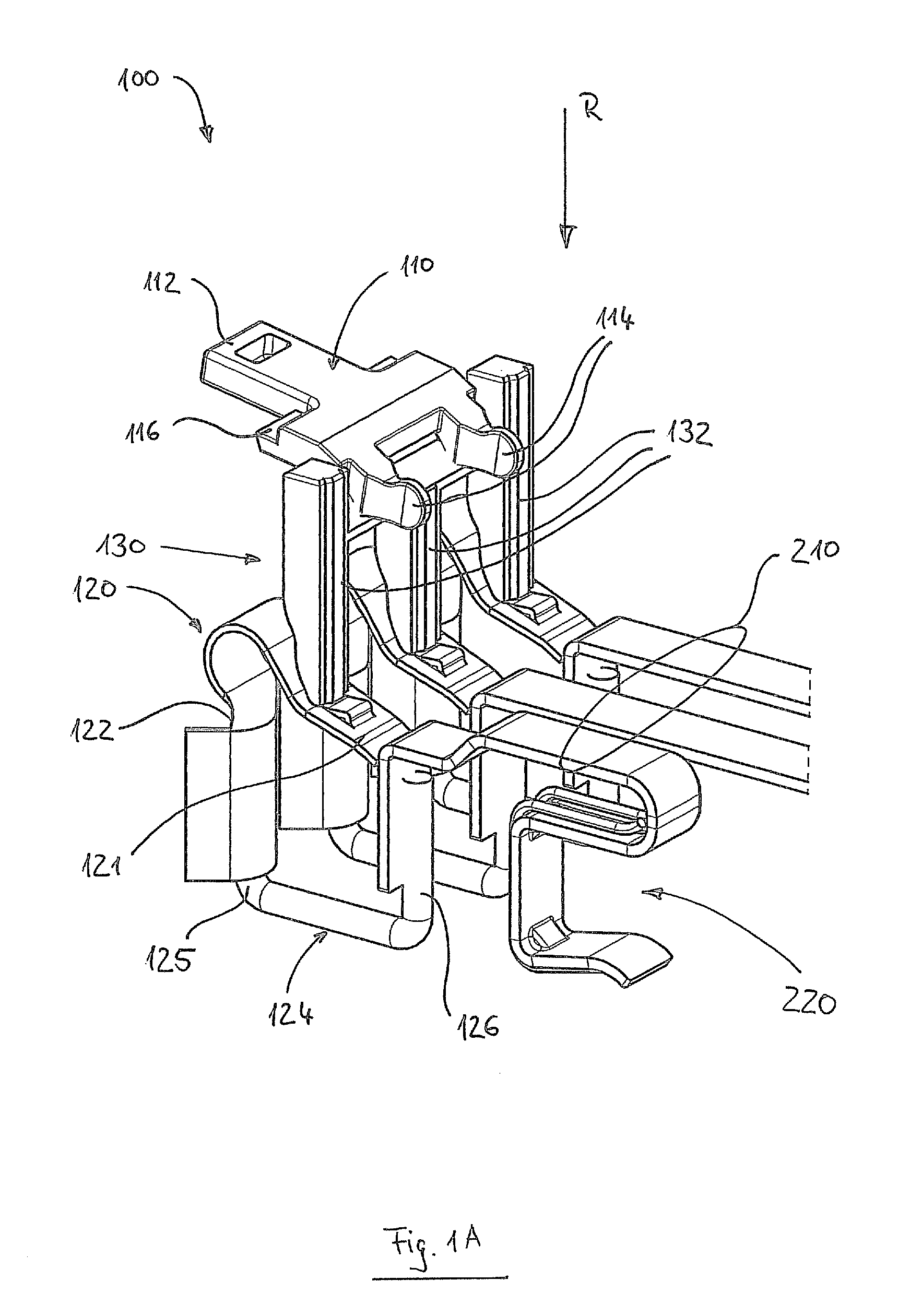

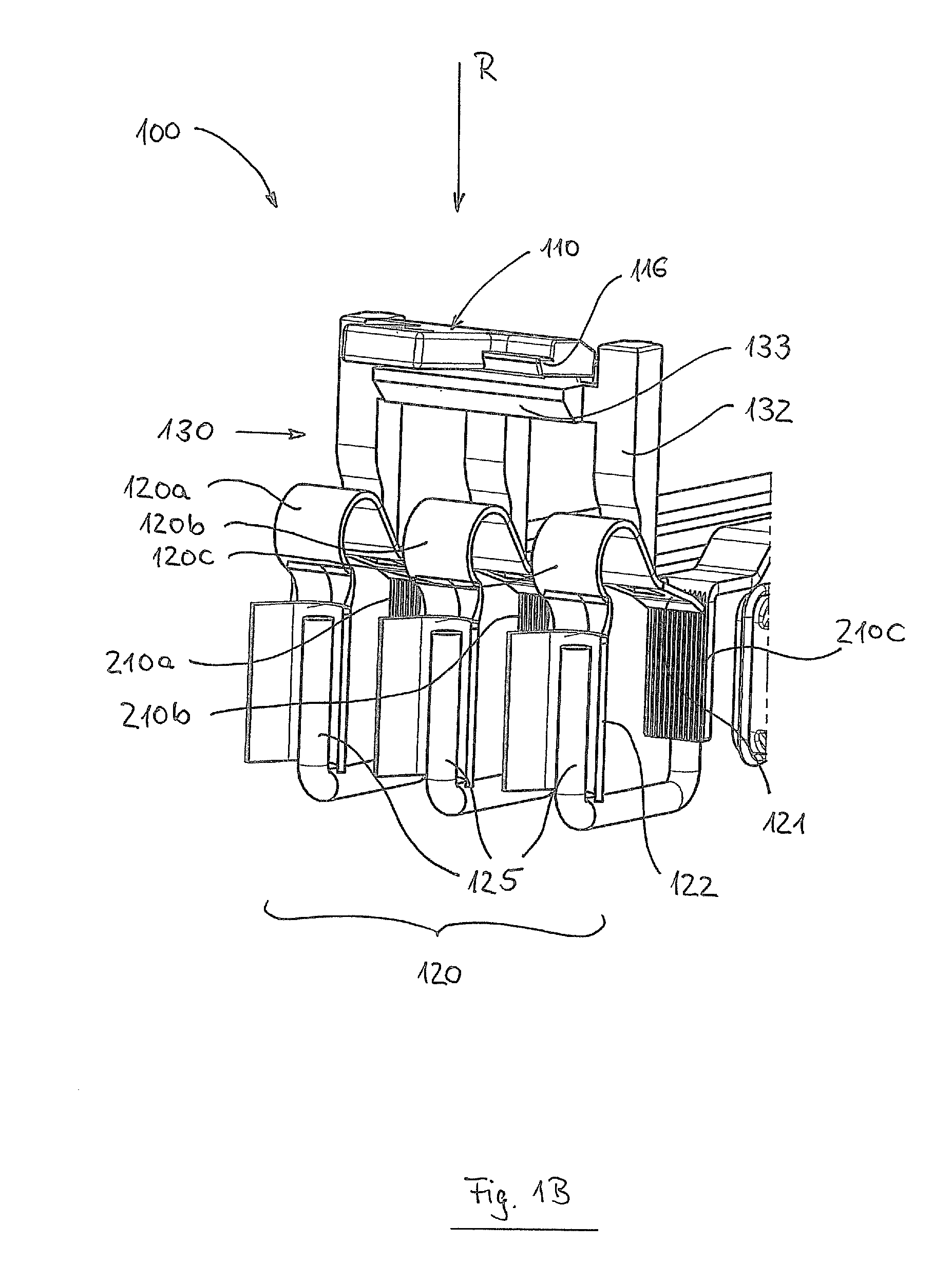

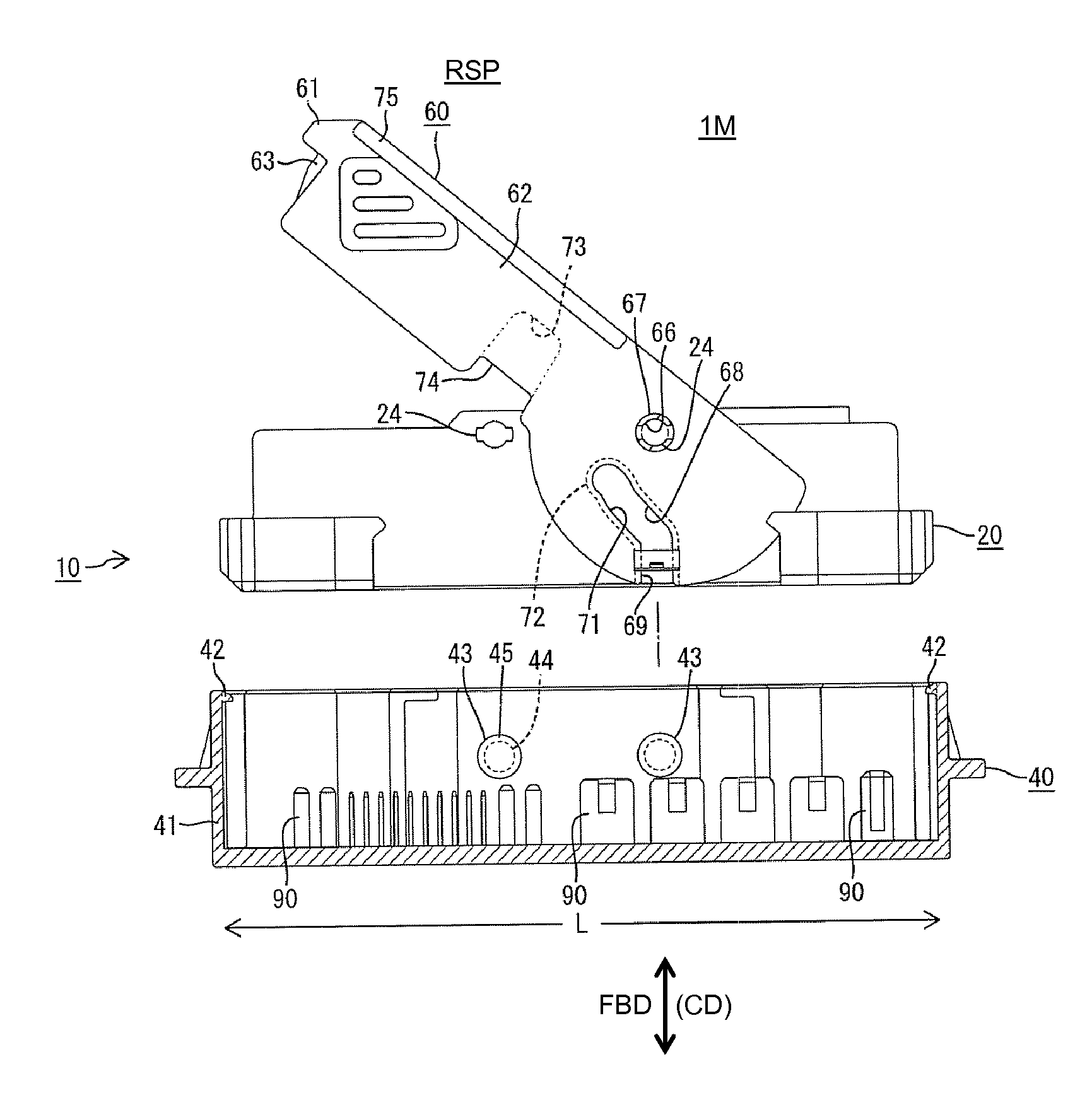

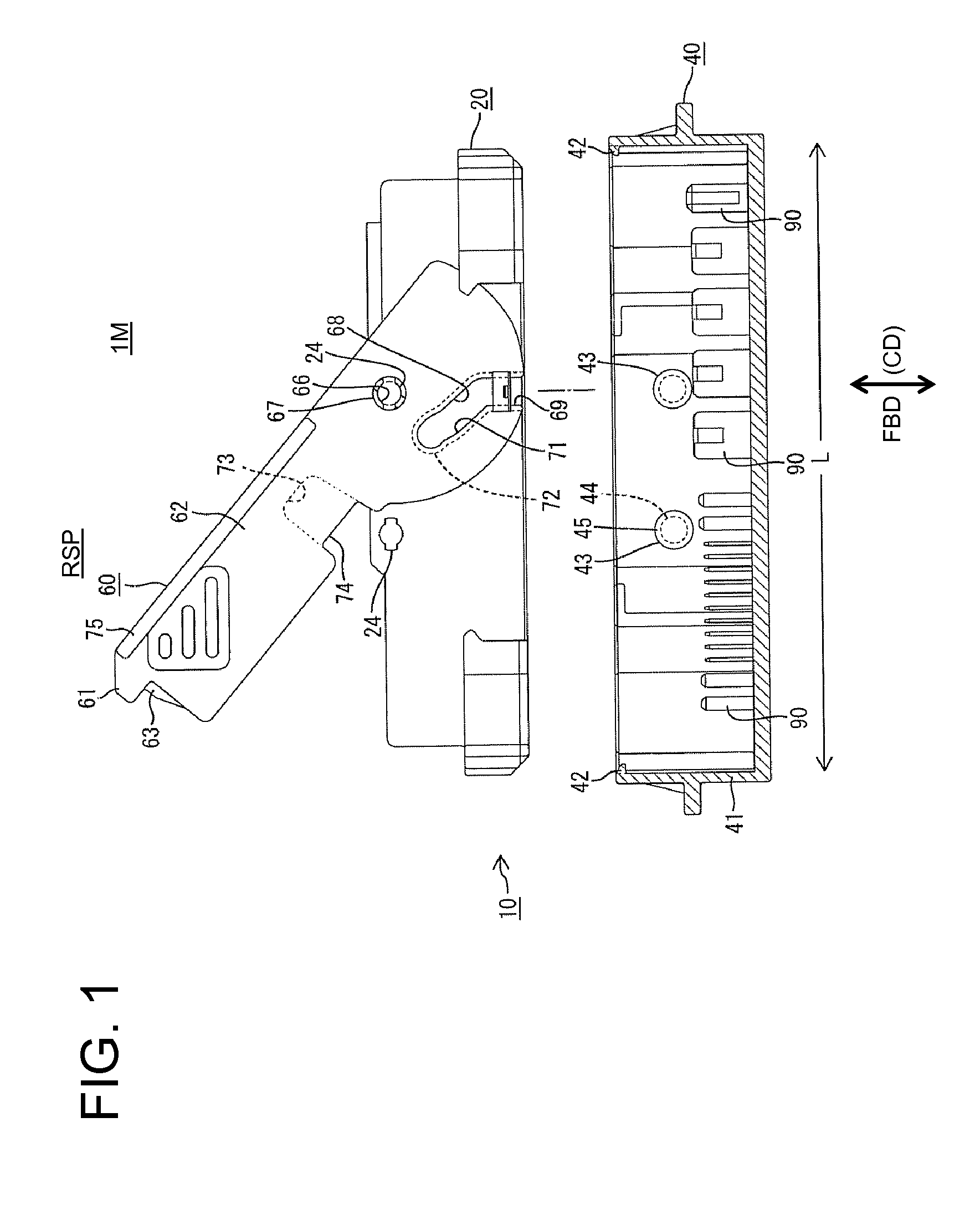

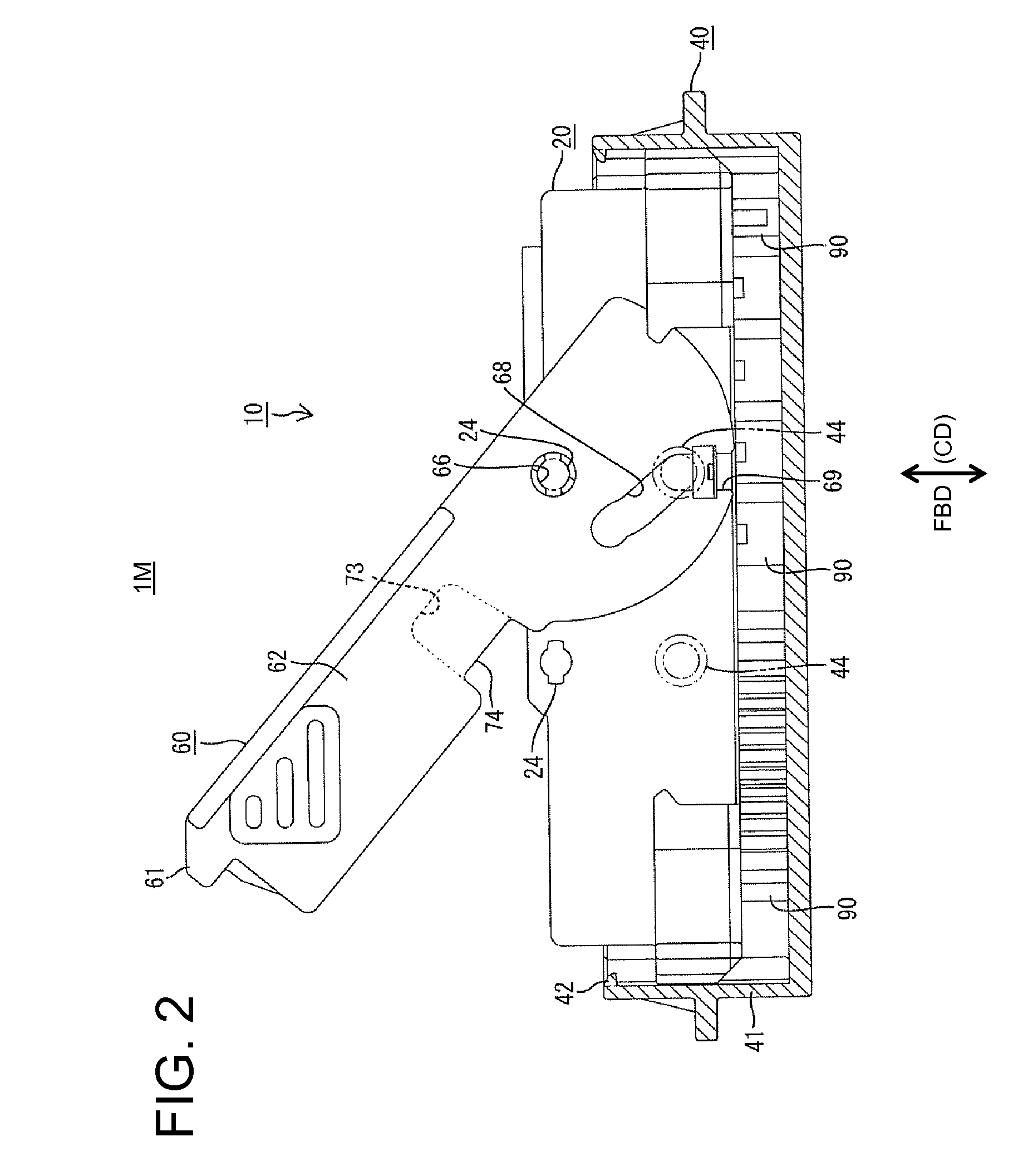

Lever-type connector and connector assembly

ActiveUS7670159B2Addressing Inadequate ContactImprove versatilityEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringCam

Two supports (24) are formed on one side surface of a first housing (20) at positions symmetrical to a center of a connection area with a second housing (40) in a lengthwise direction (L). The lever (60) is selectively mounted in a first mode on one of the two supports (24) and rotated toward one side or in a second mode on the other support (24) and rotated toward the other side. The lever (60) has a first and second parts for exerting pushing forces on the first housing (20) in a direction to proceed with a connecting operation of the housings (20, 40) as the lever (60) is rotated. The first part is a cam groove (68) engageable with a follower pin (43) of the second housing (40) and the second part is a recessed groove (73) engageable with the support (24) not supporting the lever (60).

Owner:SUMITOMO WIRING SYST LTD

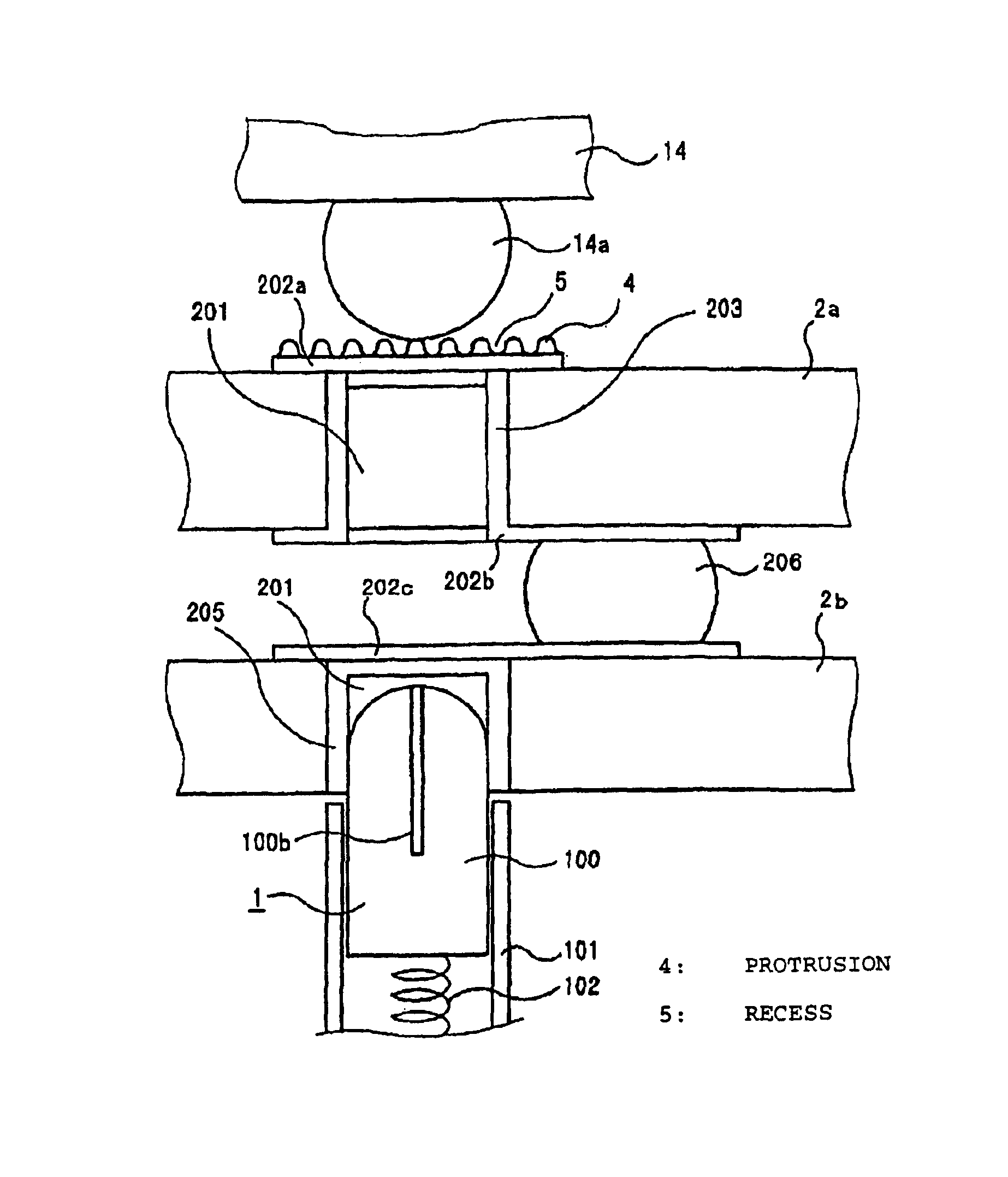

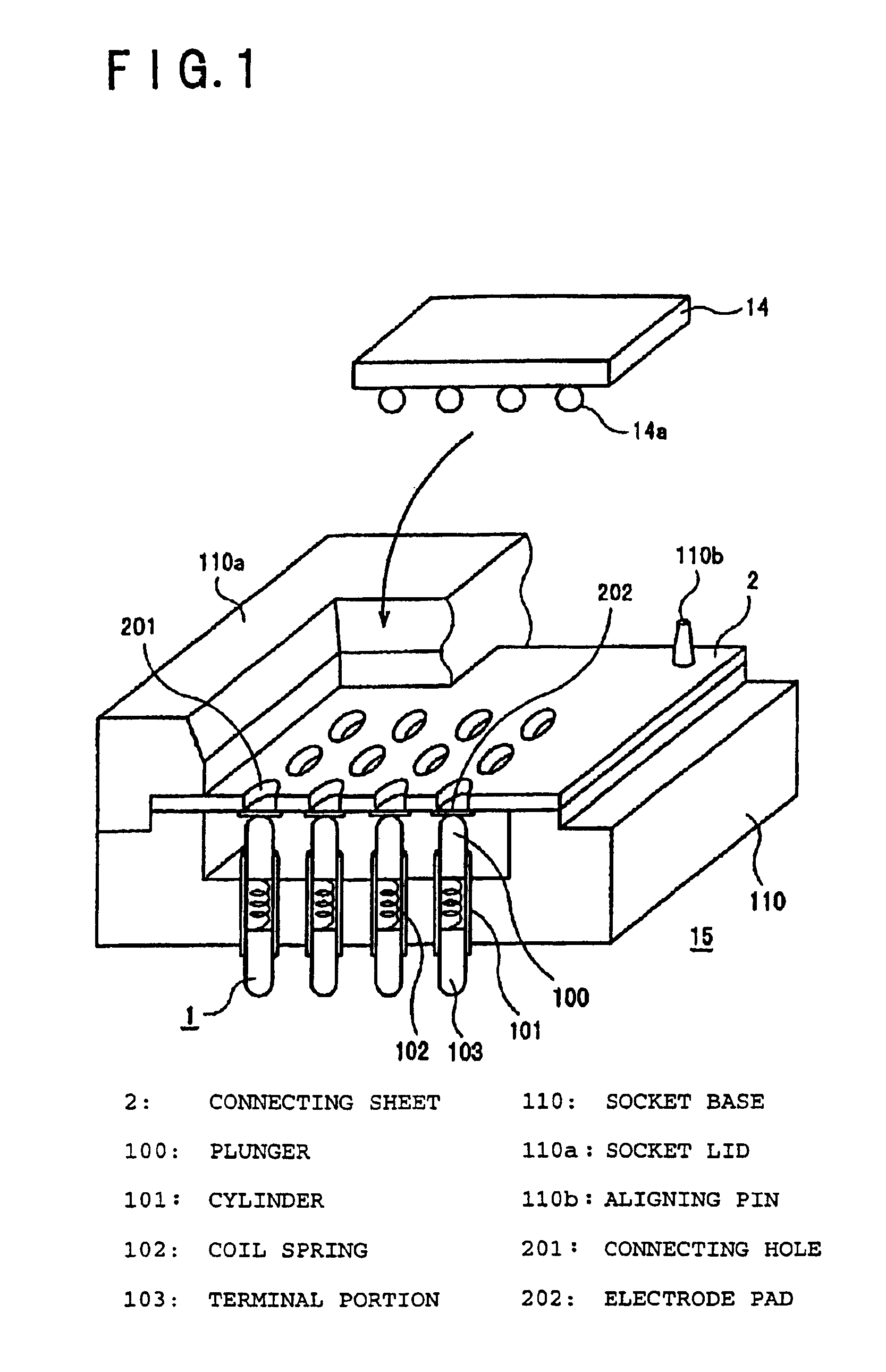

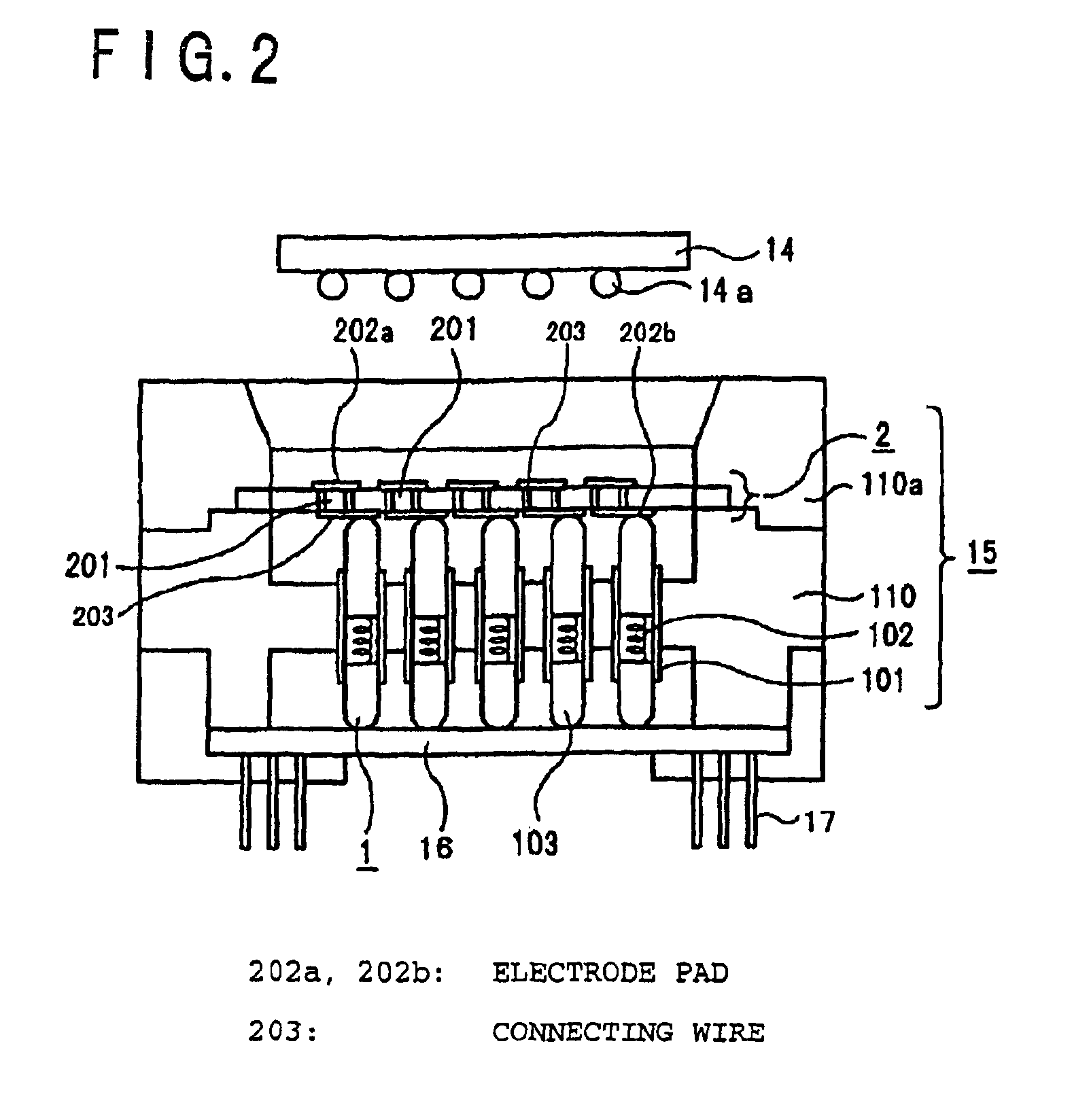

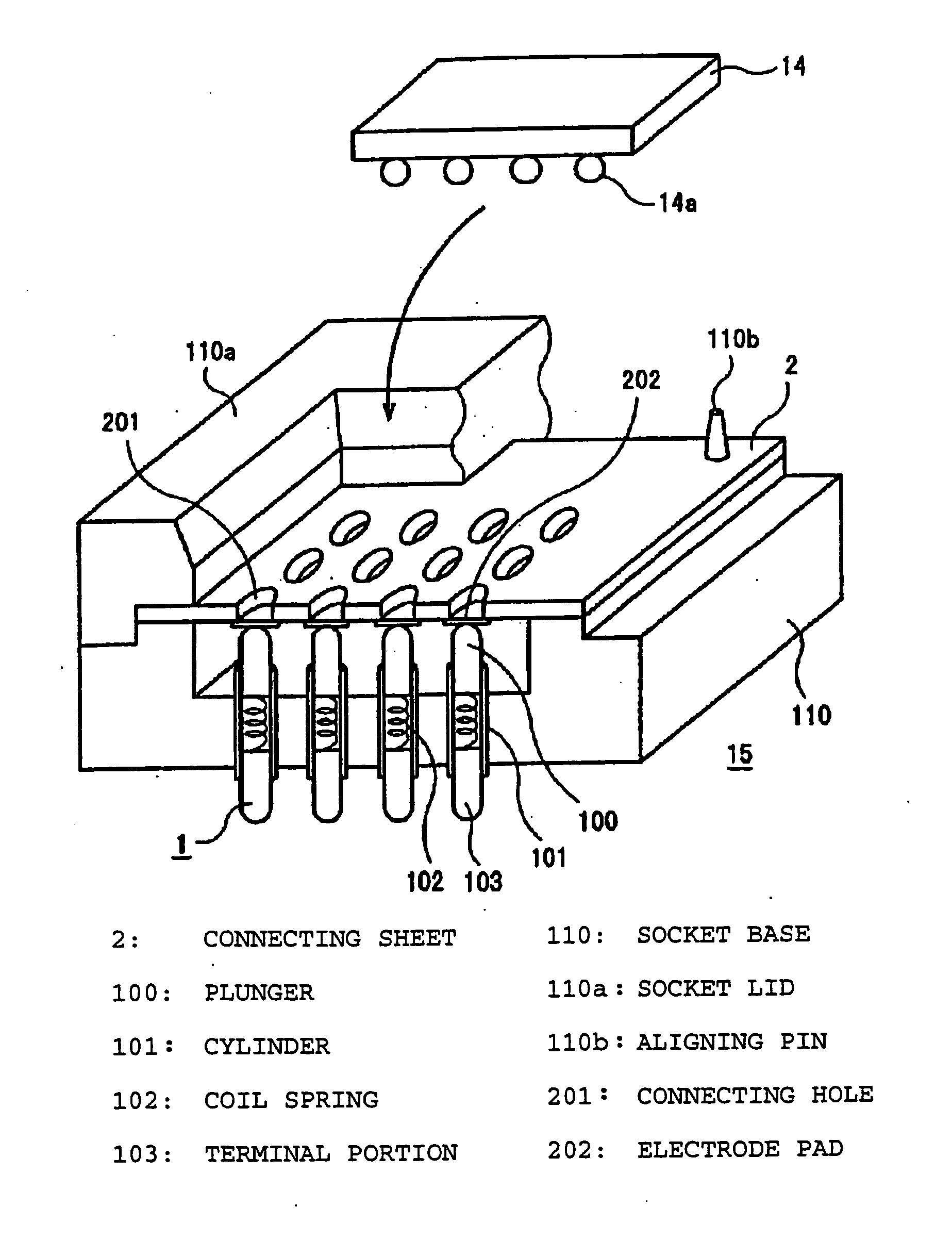

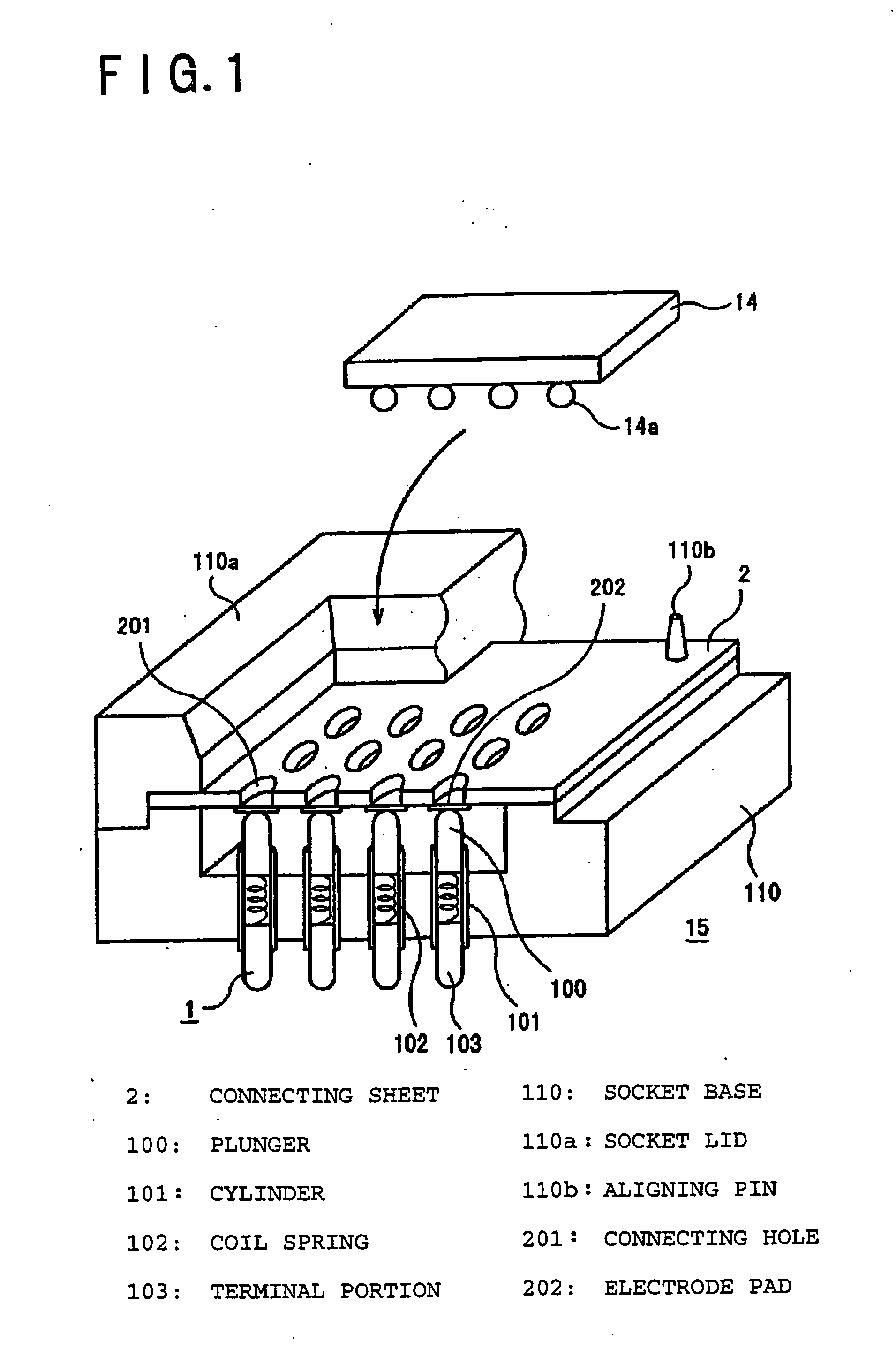

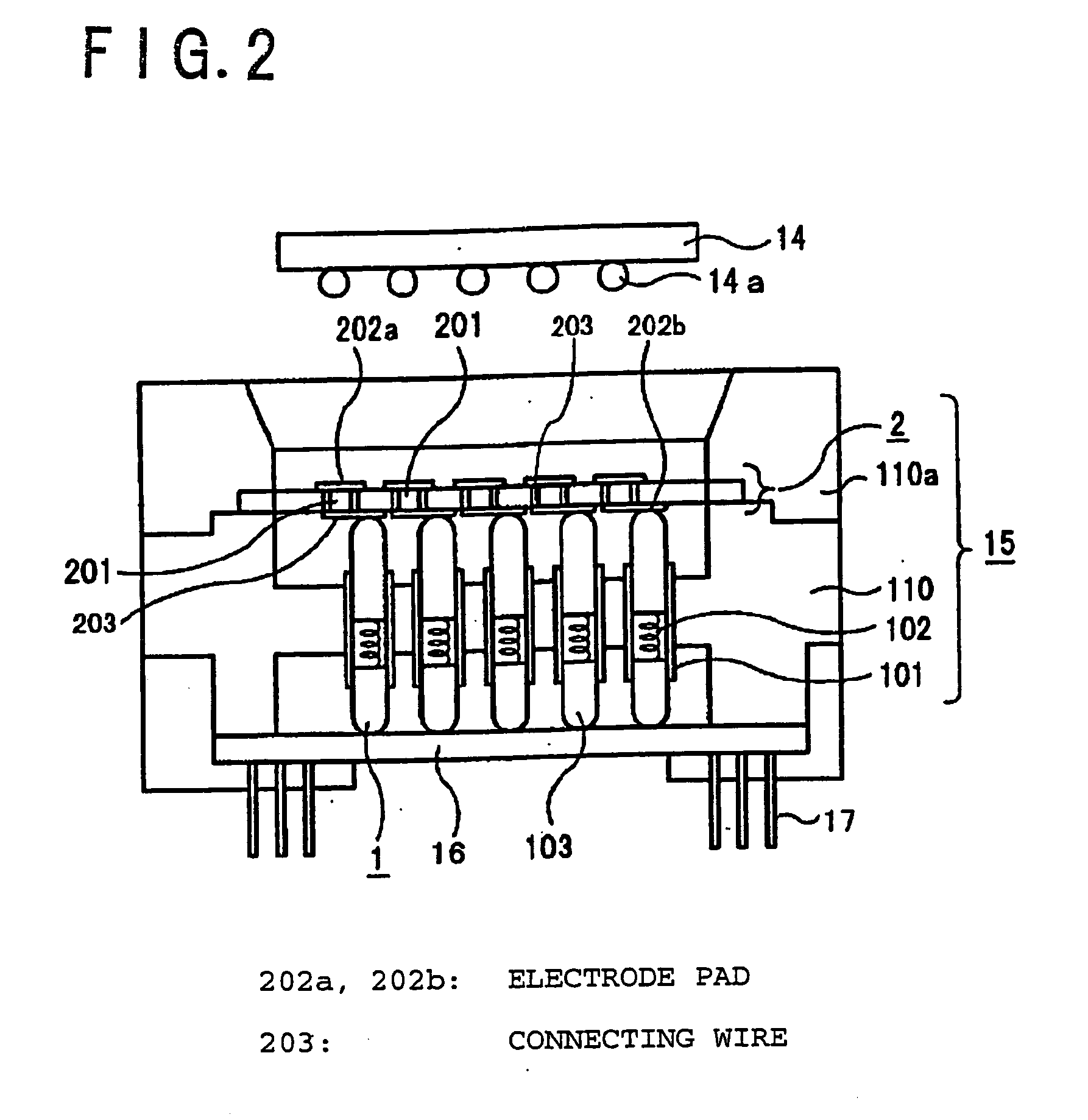

Socket for testing a semiconductor device and a connecting sheet used for the same

InactiveUS6989681B2Addressing Inadequate ContactIncrease distanceMeasurement instrument housingIndividual semiconductor device testingElectrical resistance and conductanceElectricity

Owner:MITSUBISHI ELECTRIC CORP

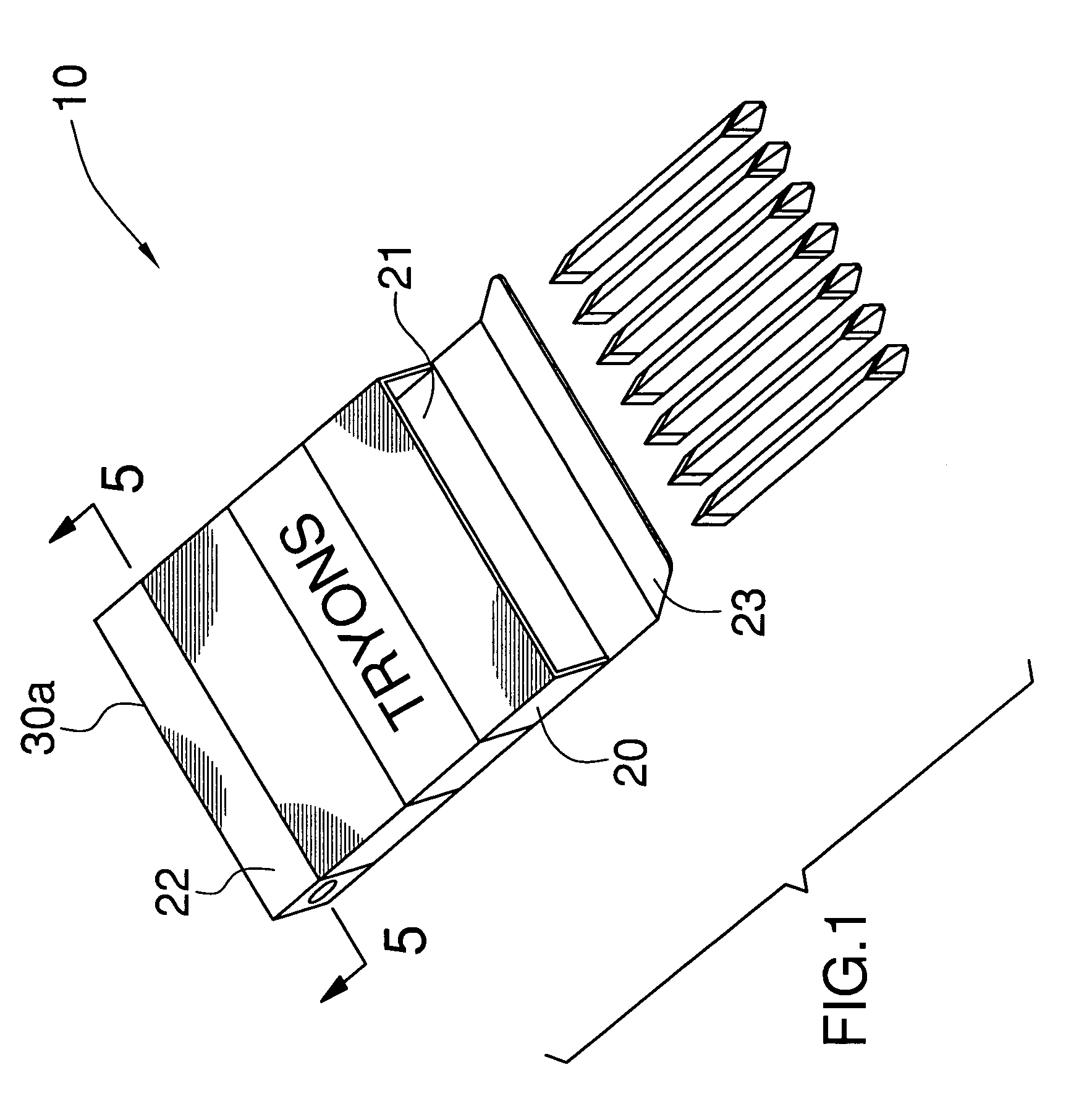

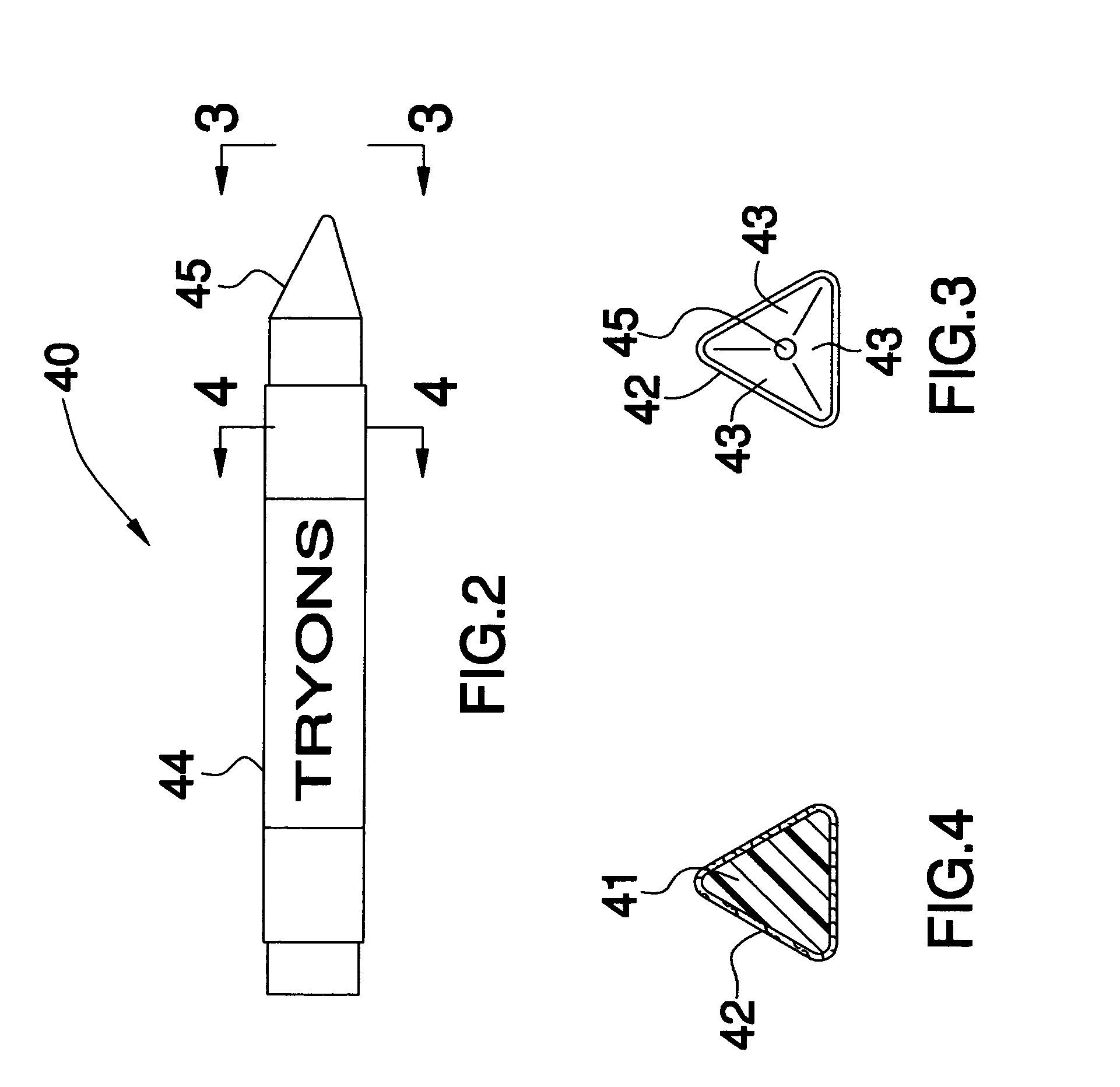

Crayons with associated carrying case

InactiveUS6887006B1Sufficient frictional contactAddressing Inadequate ContactWriting connectorsBrush bodiesEngineeringMechanical engineering

A kit for housing an improved design for crayons includes a container with two chambers. One of the chambers is provided with a blade and a rotatable member for assisting a user to position the crayons against the blade for sharpening purposes. Also included are crayons positionable into another chamber for storage. Such crayons have a plurality of integral faces equidistantly spaced apart from a centrally disposed longitudinal axis thereof respectively. The crayon faces define a plurality of angles therebetween with each of the angles equaling approximately 60 degrees, resulting in substantially triangular cross-sections defining an isometric shape.

Owner:CARPENTER TIMOTHY E

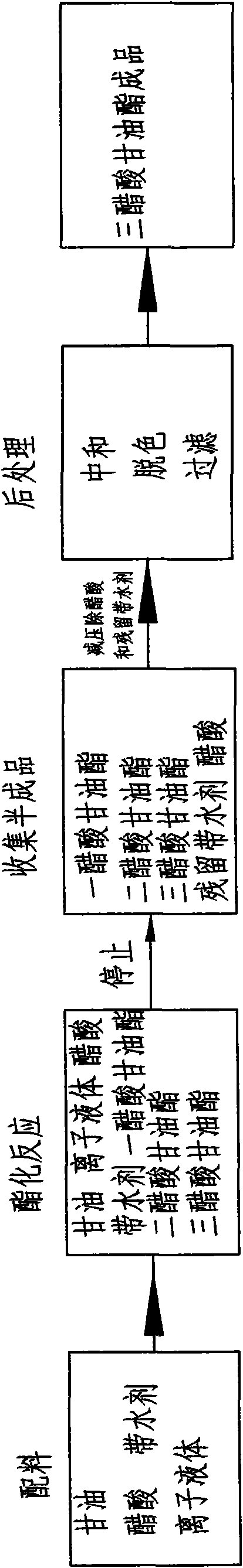

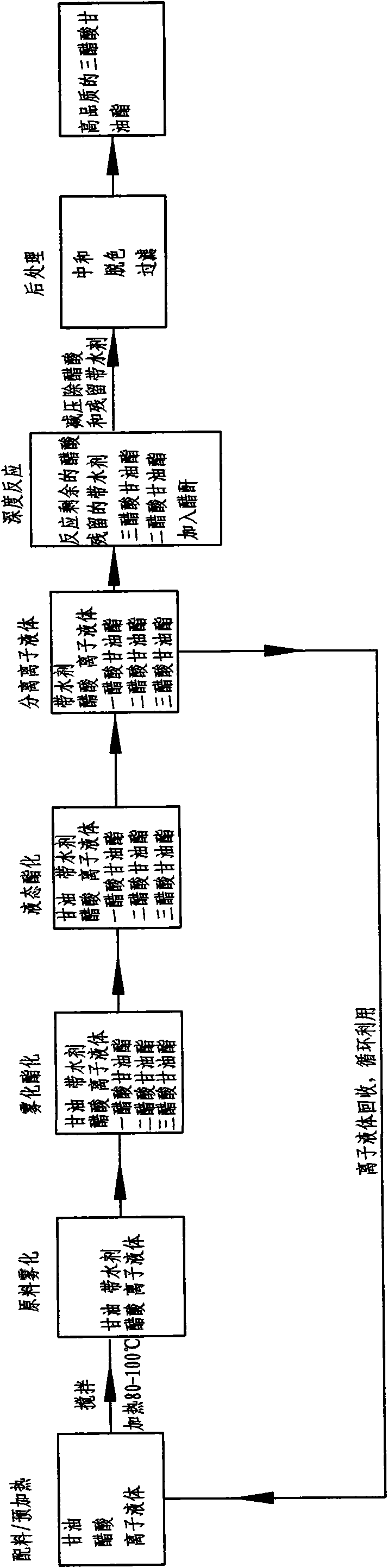

Method for producing glyceryl triacetate by atomizing raw materials

ActiveCN101613275AIncrease contentGood chromaOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

The invention discloses a method for producing glyceryl triacetate by atomizing raw materials. The production method can help shorten esterification reaction time and improve product yield, quality and chroma. The objective is achieved in virtue of the following technical scheme: mixing glycerol and acetic acid at a mol ratio of 1:6-9; adding a proper amount of a liquid catalyst and an entrainer,stirring and preheating to 80-100 DEG C; atomizing the mixture to allow the mixture to be subject to esterification reaction at 100-120 DEG C for 1-2h to obtain a liquid mixture containing 98-99% of glyceryl triacetate; adding 1-1.5% of acetic anhydride to the obtained liquid mixture for deep esterification reaction at the temperature of 90-110 DEG C for 10-20min to obtain a semi-finished product; removing the entrainer and the acetic acid, neutralizing, decoloring and filtering to obtain the glyceryl triacetate finished product.

Owner:云南玉溪环腾科工贸有限公司

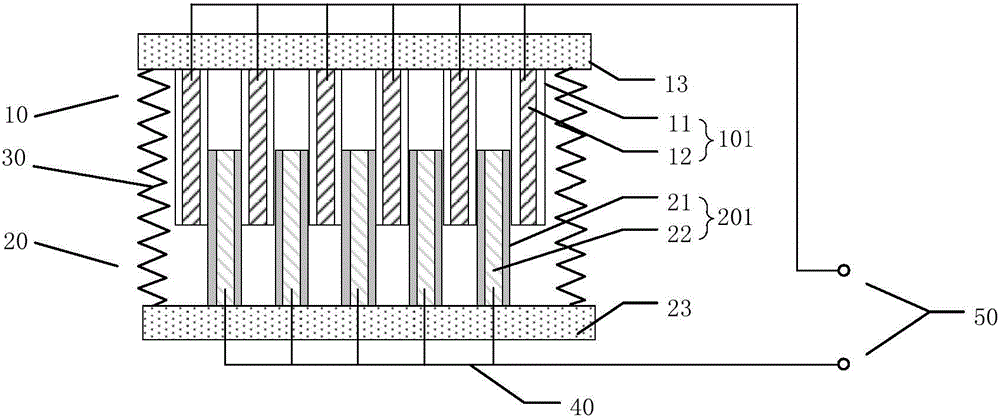

Electrochemical device

ActiveUS8173326B2Easily and effectively attachedHigh peak powerCellsElectrode carriers/collectorsPolymer electrolytesElectrical battery

A polymer electrolyte electrochemical device includes an anode current collector (1), a membrane electrode assembly (2) with anode and cathode gas backings (3, 4), and a cathode current collector (5), wherein the membrane electrode assembly is sealed and attached at least to the anode current collector by adhesive elements, thereby creating an anode gas chamber, and optionally attached to the cathode current collector by adhesive elements, the adhesive elements being electrically conducting or electrically non-conducting. The invention also relates to polymer electrolyte electrochemical device components adapted for use in a single cell electrochemical device and a series arrangement electrochemical device.

Owner:FUEL CELL TECH SWEDEN AB

Positive electrode plate and polymer electrolyte membrane combined piece and preparation method thereof

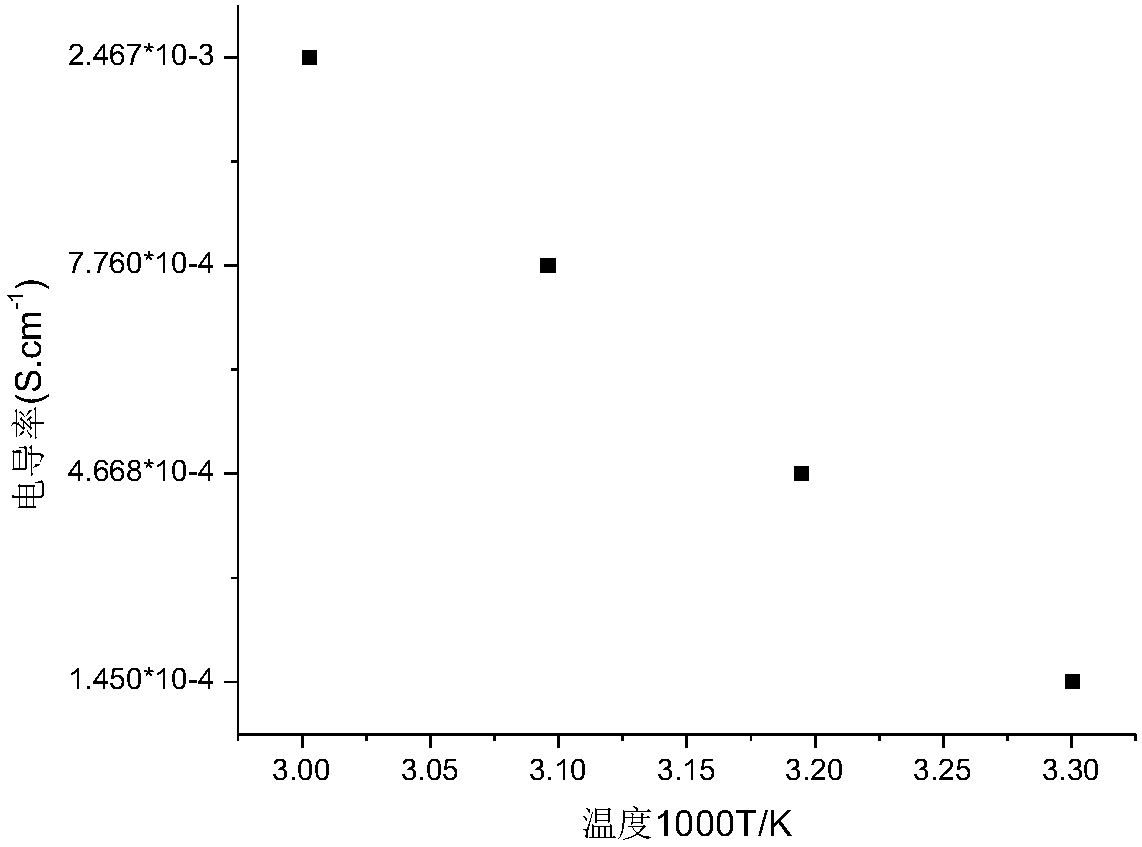

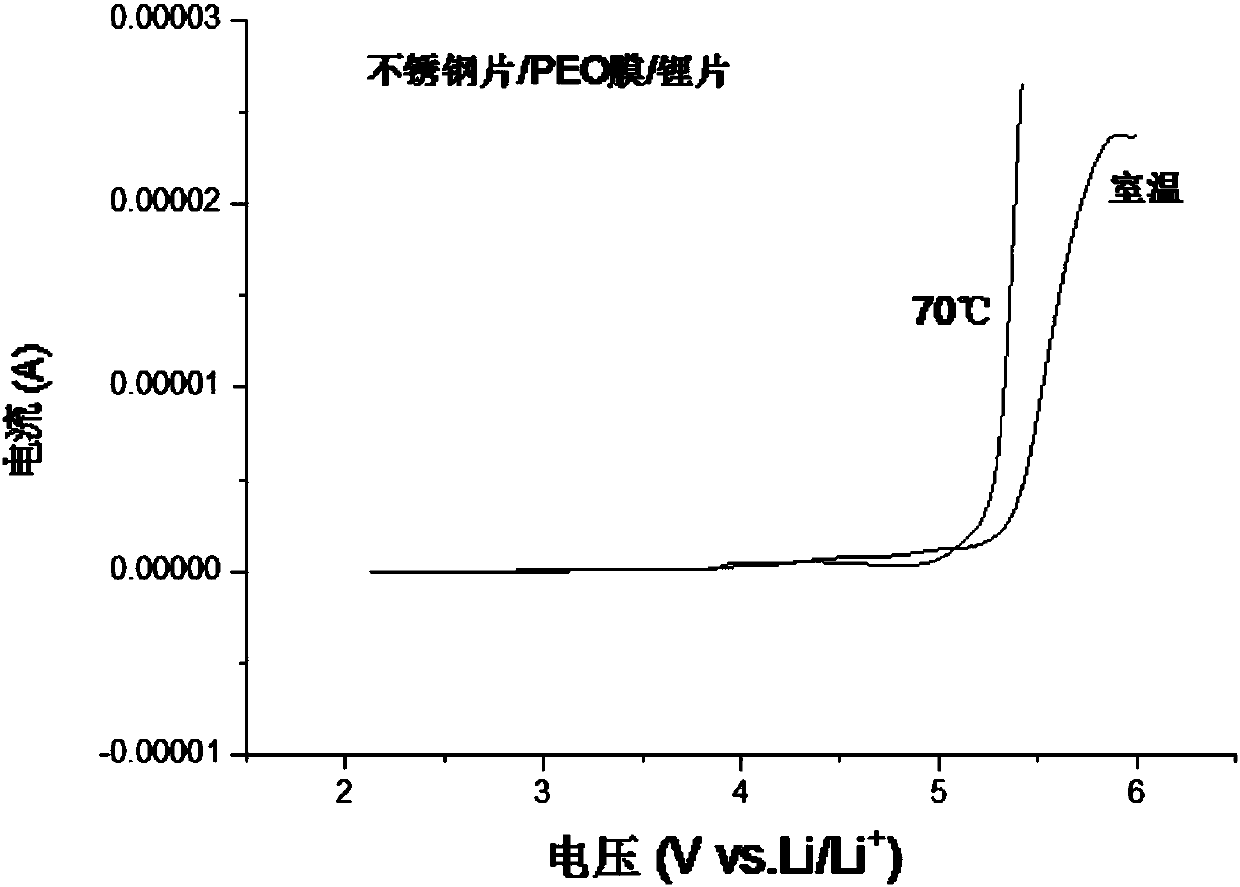

ActiveCN110323493AImprove electrochemical performanceImprove Coulombic efficiencySolid electrolytesCell electrodesSolid state electrolytePolymer electrolytes

The invention provides a preparation method of a positive electrode plate and polymer electrolyte membrane combined piece. The preparation method comprises the following steps: (1) carrying out ball-milling treatment on a positive active material and a ceramic-based solid electrolyte; (2) under heating, dissolving a polymer binder in an organic solvent, adding lithium salt, and performing stirringto completely dissolve the lithium salt; (3) taking the solution obtained at the step (2), adding a ceramic-based solid electrolyte, performing stirring, pouring the mixture into a mold, and evaporating the solvent to dryness to prepare a polymer electrolyte membrane; (4) taking the solution prepared at the step (2), adding the positive active material and the conductive additive at the step (1),performing stirring, coating an aluminum foil with the solution, and performing drying to obtain a positive electrode plate; (5) tabletting the positive electrode plate, combining positive electrodeplate with the polymer electrolyte membrane at the step (3), performing tabletting, and carrying out melting treatment to obtain the combined piece. According to the method, the compatibility of the positive electrode plate and the electrolyte membrane can be improved, the solid-solid interface contact of the solid-state battery is increased, and the impedance is reduced; the coulombic efficiencyof the battery is effectively improved, and the advantages of the electrode material are fully exerted.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

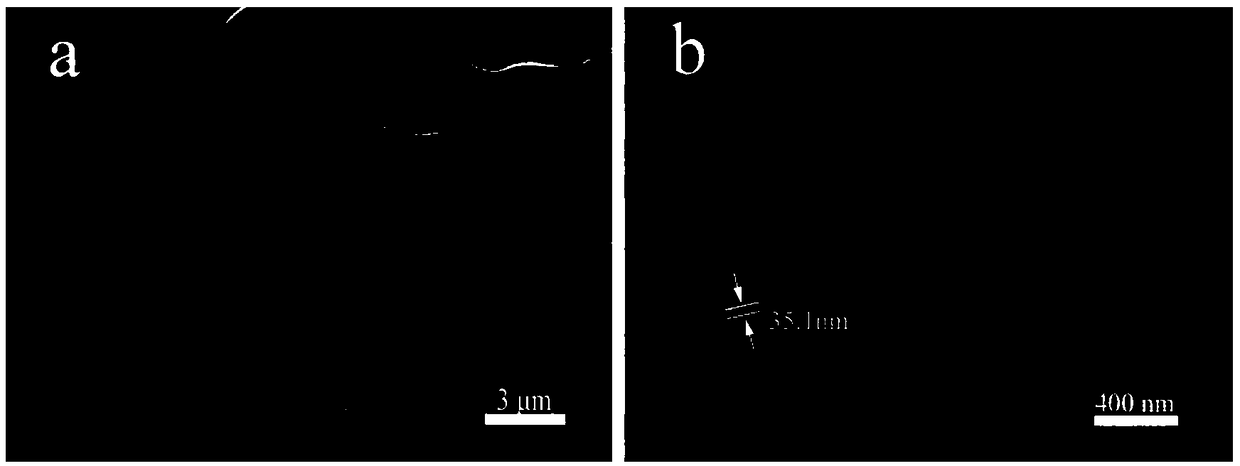

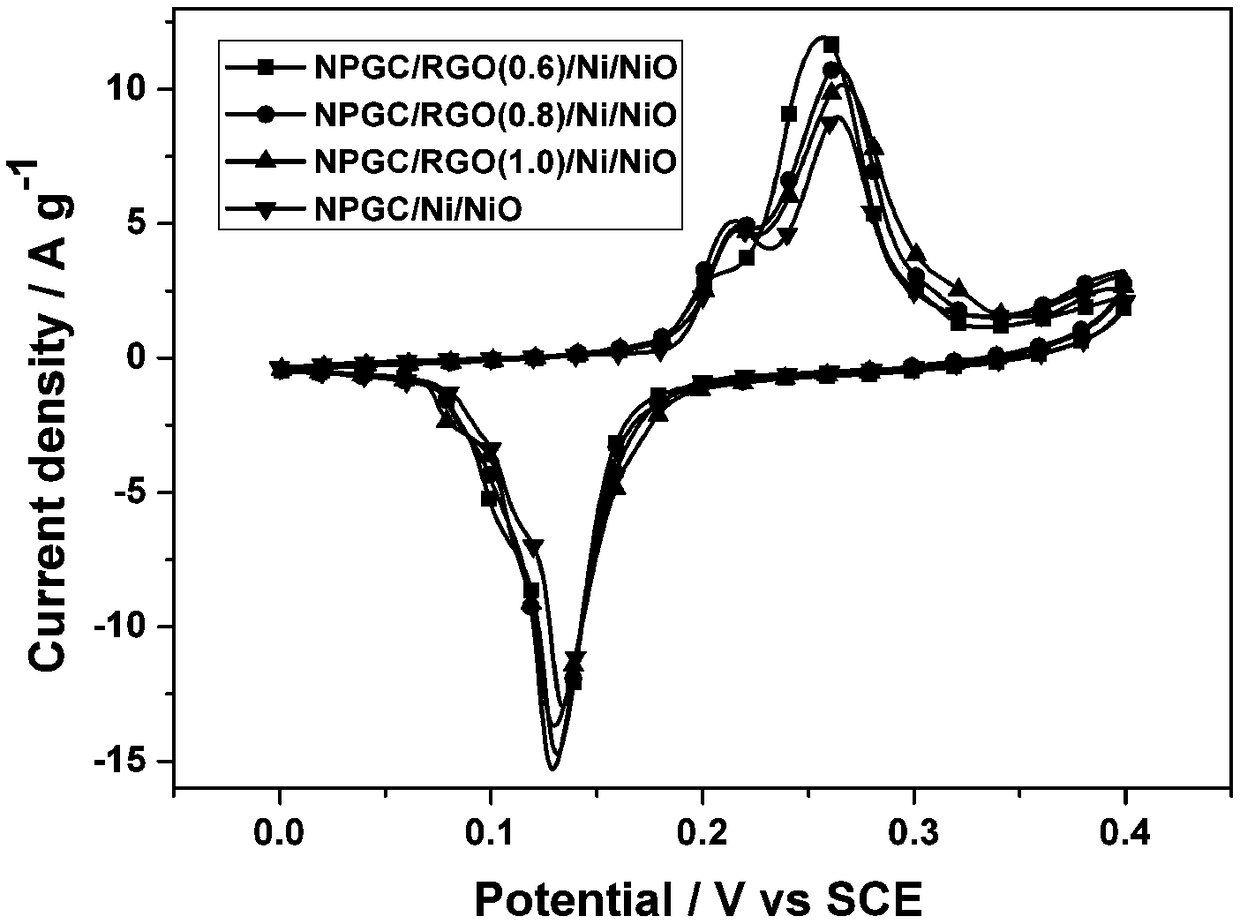

Graphene/nitrogen doped carbon/nickel/nickel oxide composite material preparation method

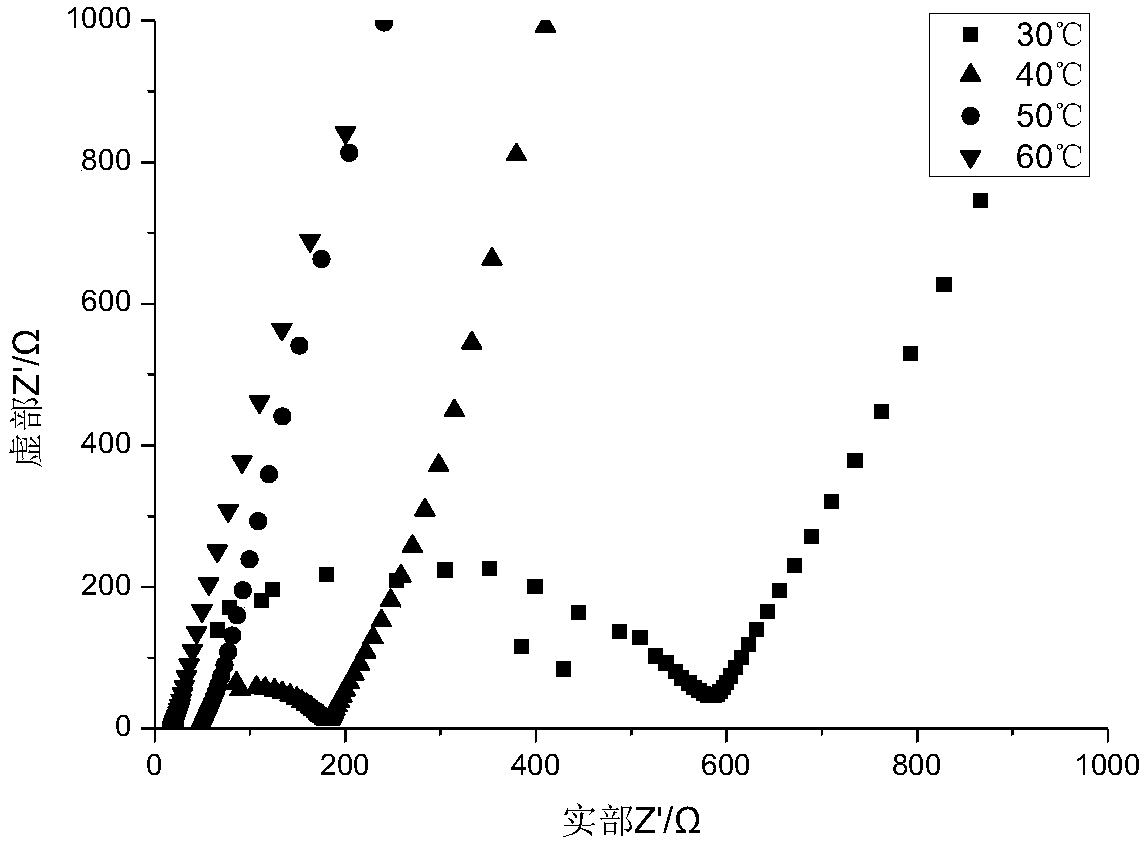

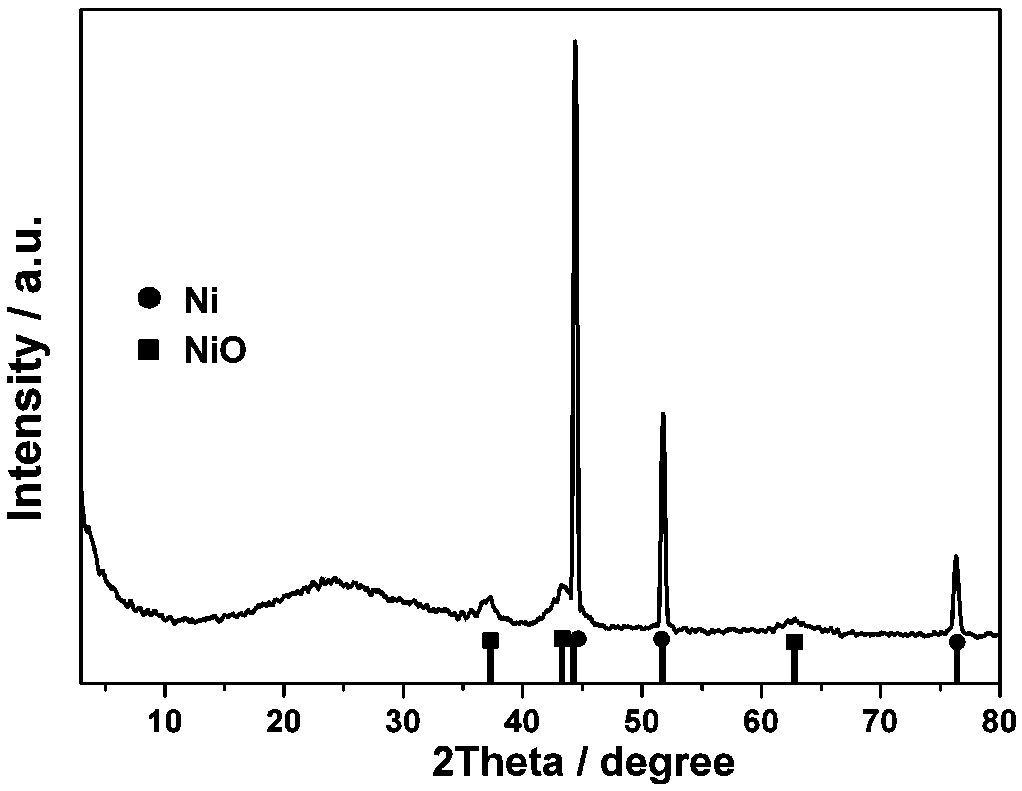

ActiveCN108962632AHigh specific capacitanceImprove featuresMaterial nanotechnologyHybrid capacitor electrodesCapacitanceCompound specific

The invention belongs to the energy storage material technical field, and relates to a graphene / nitrogen doped carbon / nickel / nickel oxide composite material preparation method; the method is applied to a super capacitor electrode material preparation occasion, and solves the problems that an existing process is complex in preparation steps, long in time consumption, low in compound specific capacitance, and hard in material applications. The method comprises the following steps: employing a reduction oxidation graphene / crosslinking polyacrylamide / nickel salt aerogel as a precursor; calcining same to realize carbon material in situ nitrogen doping, carbon hot reduction, and catalysis graphitization; and compositing same with the reduction oxidation graphene to form a 3D structure graphene / nitrogen doped carbon / nickel / nickel oxide quaternary nano composite material. The preparation process is simple, and reliable in principles; the composite material can serve as the super capacitor electrode material, is low in equivalent resistance, low in interface charge transfer resistance and Warburg impedance, high in product specific capacitance, excellent in electrochemistry performance, andhas excellent economic benefits and application prospects.

Owner:QINGDAO UNIV OF SCI & TECH

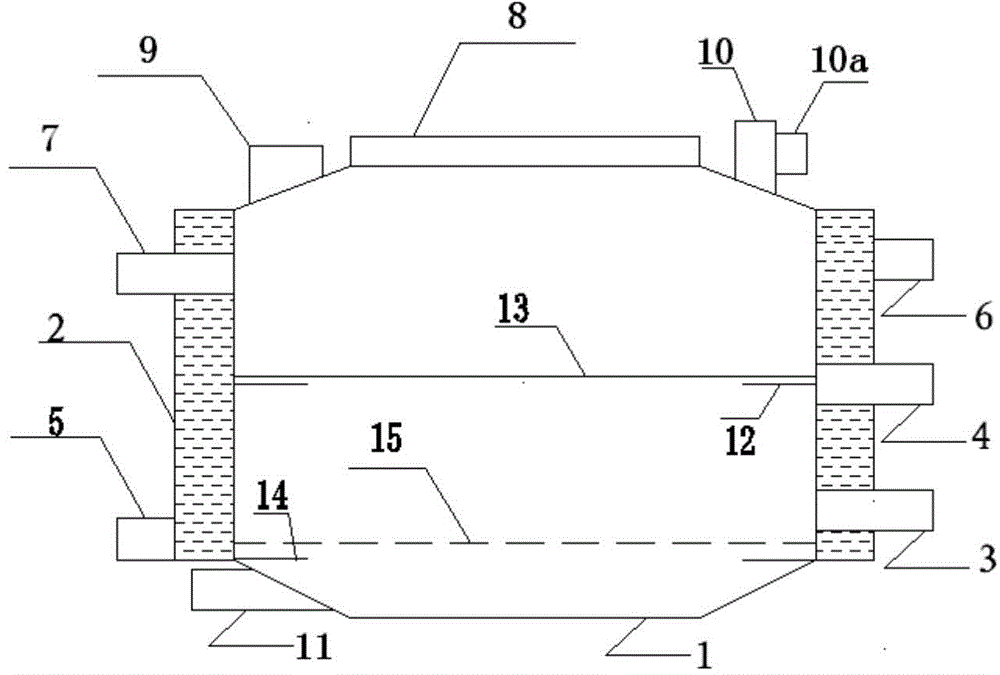

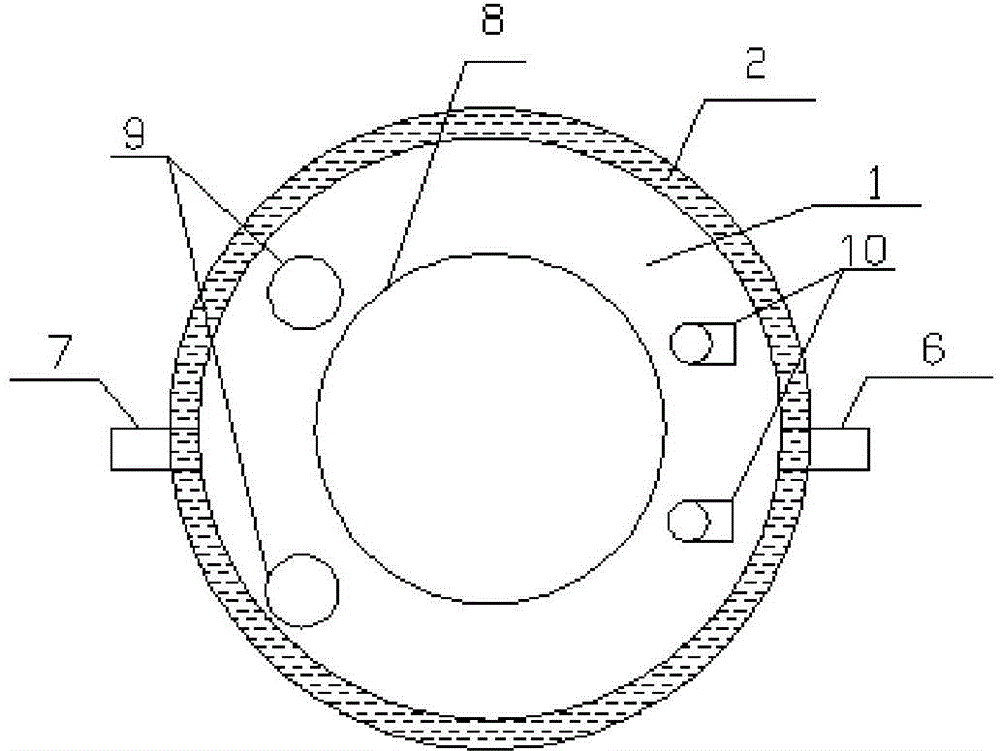

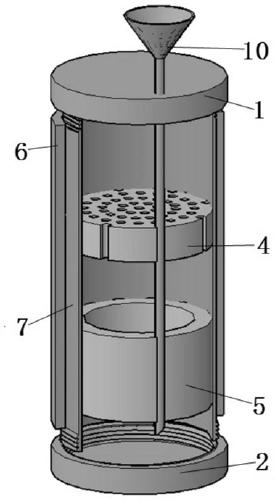

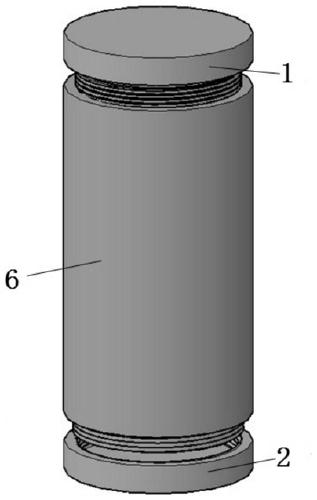

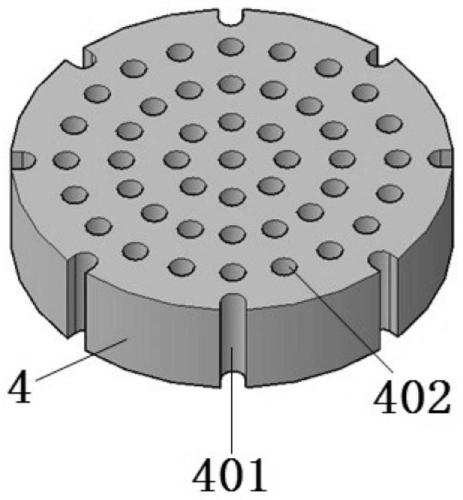

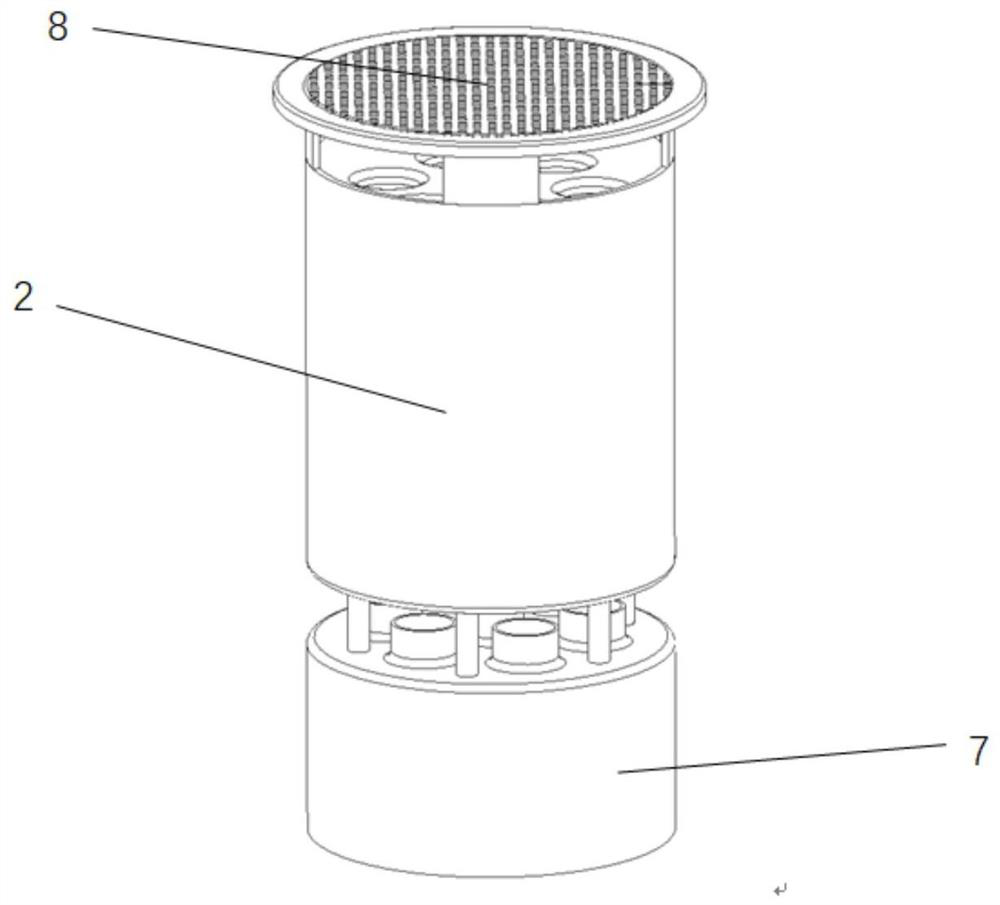

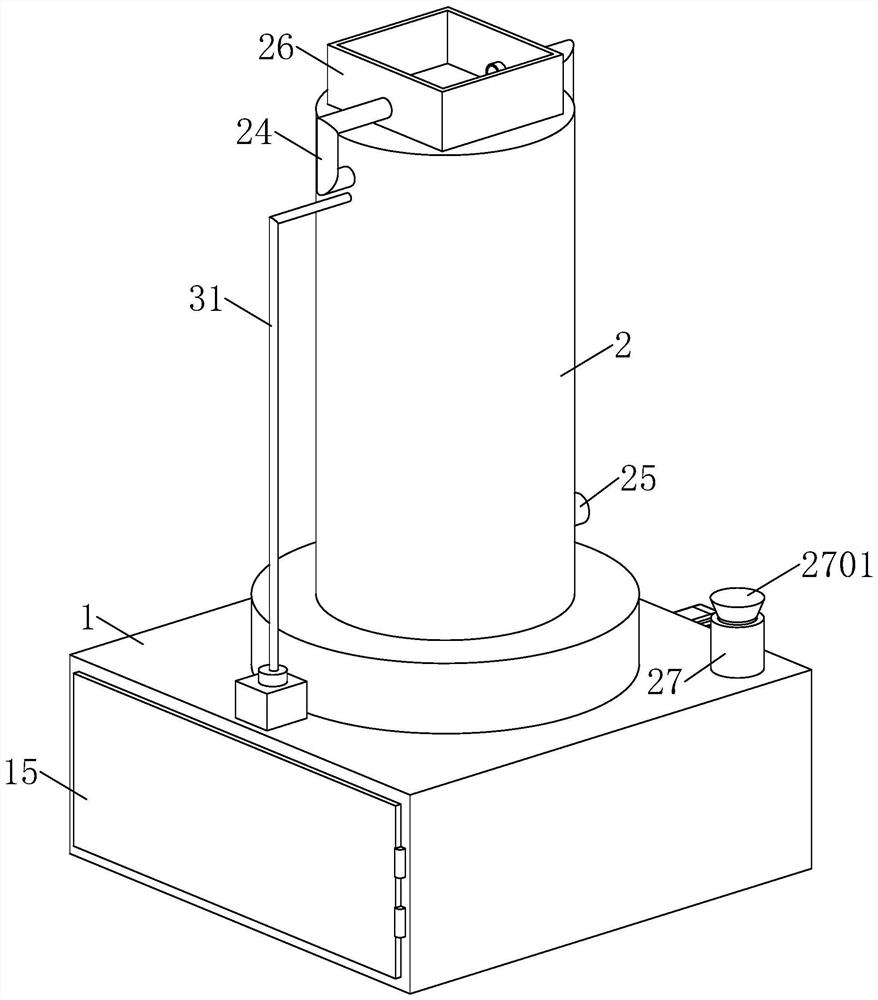

Device and method for quickly enriching Nx-DAMO bacteria

InactiveCN104611193APromote rapid growthAchieve rapid enrichmentBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringAeration

The invention relates to a device for quickly enriching Nx-DAMO bacteria. The device comprises a reactor main body, wherein an outer housing is arranged outside the side wall of the reactor main body; an interlayer cavity is formed between the reactor main body and the outer housing; a water bath inlet and a water bath outlet, which are communicated with the interlayer cavity, are formed in the outer housing; a liquid outlet pipe, a liquid inlet pipe and a reserving pipe are arranged on the reactor main body; a top cover is arranged at the top end of the reactor main body; an electrode port and a gas production pipe are arranged at the upper end of the reactor main body; an exhaust branch pipe is arranged on the gas production pipe; a gas inlet pipe is arranged at the bottom of the reactor main body; an adsorption layer support frame is arranged in a circumferential direction in the middle of the inner side wall of the reactor main body; an adsorption layer is mounted on the adsorption layer support frame; an aeration plate support frame is arranged in the circumferential direction at the lower part of the inner wall of the reactor main body; and an aeration plate is mounted on the aeration plate support frame. The invention further relates to a method for quickly enriching Nx-DAMO bacteria with the device.

Owner:CHONGQING UNIV

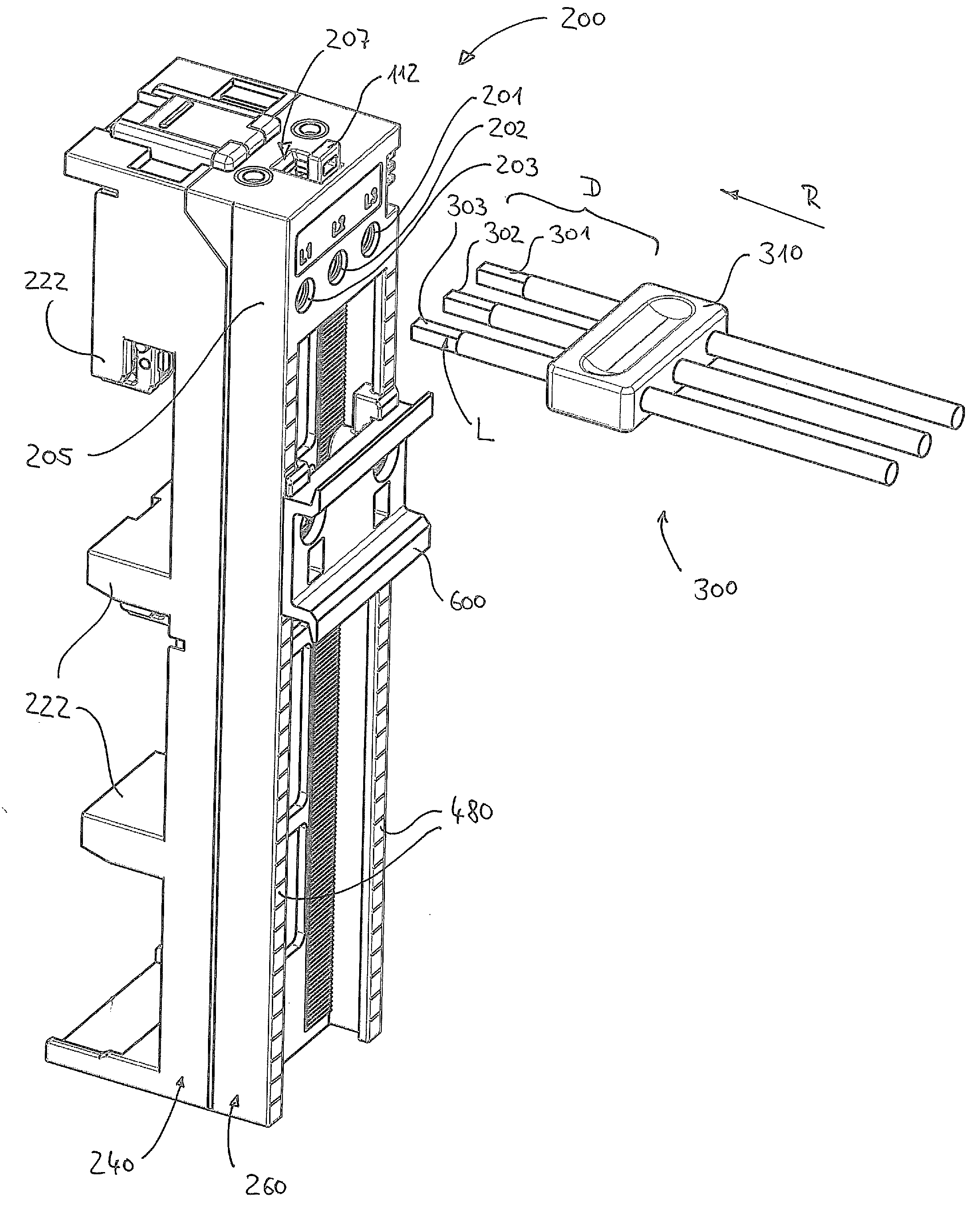

Adapter For Contacting Bus Bars

InactiveUS20150093925A1Simple pulling-outConvenient lengthEngagement/disengagement of coupling partsBus-bar/wiring layoutsBusbarSpring force

An adapter for contacting busbars with a multi-pole connecting cable is disclosed with at least two contact connections for at least two busbars; a housing having holding means; and a cable-connecting device that is secured in the housing by the holding means. The cable-connecting device has: a lever switch; a spring-terminal structure; and a connecting structure. The lever switch has a fulcrum onto which a leverage acts when the lever switch is actuated. The spring-terminal structure provides a spring force for establishing an electrical contact between one of the plurality of poles and one of the at least two contact connections by the spring force after inserting the connecting cable. The connecting structure is arranged between the lever switch and the spring-terminal structure and is designed for transferring the leverage from the lever switch to the spring-terminal structure and to tension the spring-terminal structure counter to the spring force.

Owner:KLAUS BRUCHMANN

Lever-type connector and connector assembly

ActiveUS20090170358A1Addressing Inadequate ContactImprove versatilityEngagement/disengagement of coupling partsIncorrect coupling preventionCamElectrical and Electronics engineering

Two supports (24) are formed on one side surface of a first housing (20) at positions symmetrical to a center of a connection area with a second housing (40) in a lengthwise direction (L). The lever (60) is selectively mounted in a first mode on one of the two supports (24) and rotated toward one side or in a second mode on the other support (24) and rotated toward the other side. The lever (60) has a first and second parts for exerting pushing forces on the first housing (20) in a direction to proceed with a connecting operation of the housings (20, 40) as the lever (60) is rotated. The first part is a cam groove (68) engageable with a follower pin (43) of the second housing (40) and the second part is a recessed groove (73) engageable with the support (24) not supporting the lever (60).

Owner:SUMITOMO WIRING SYST LTD

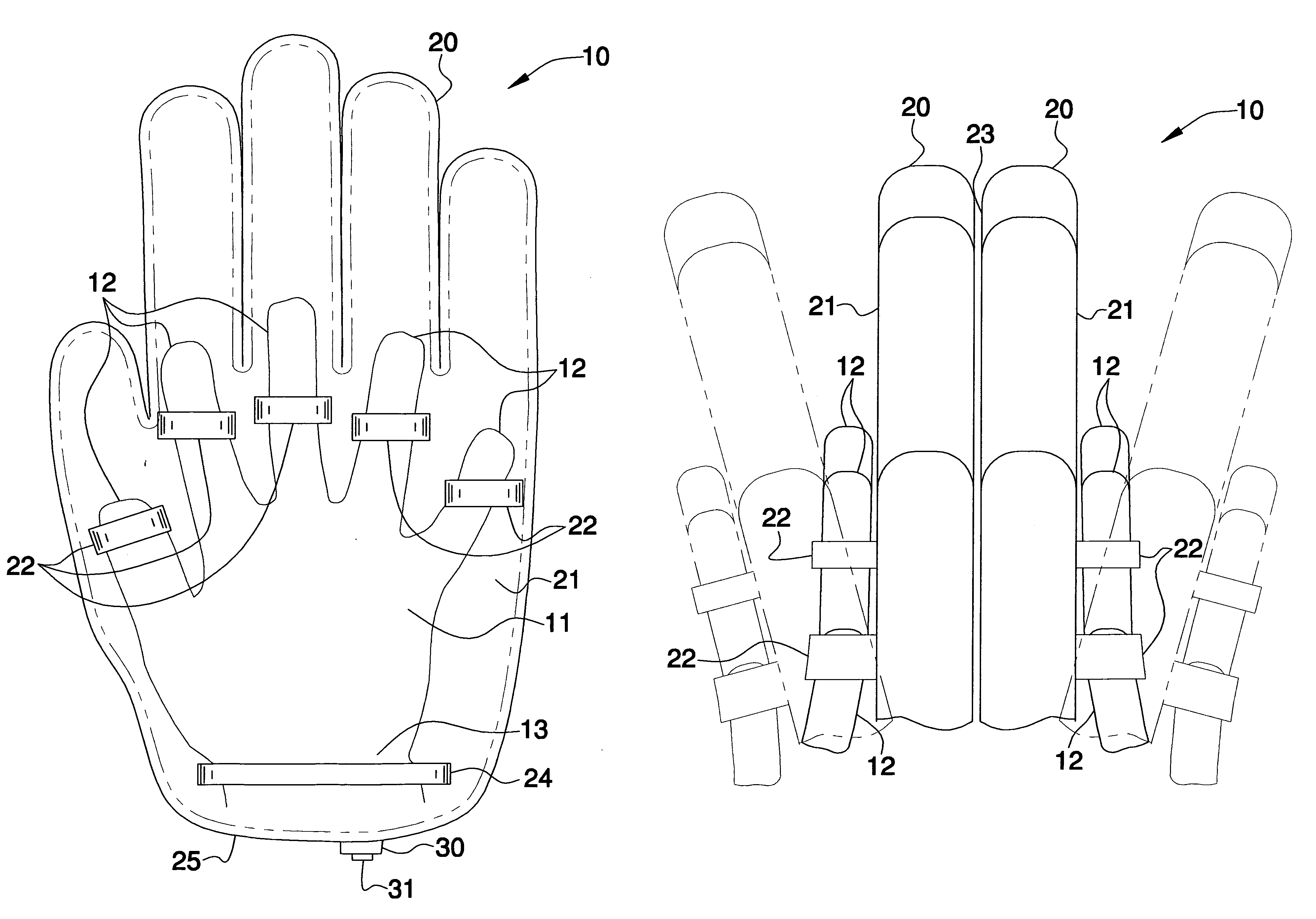

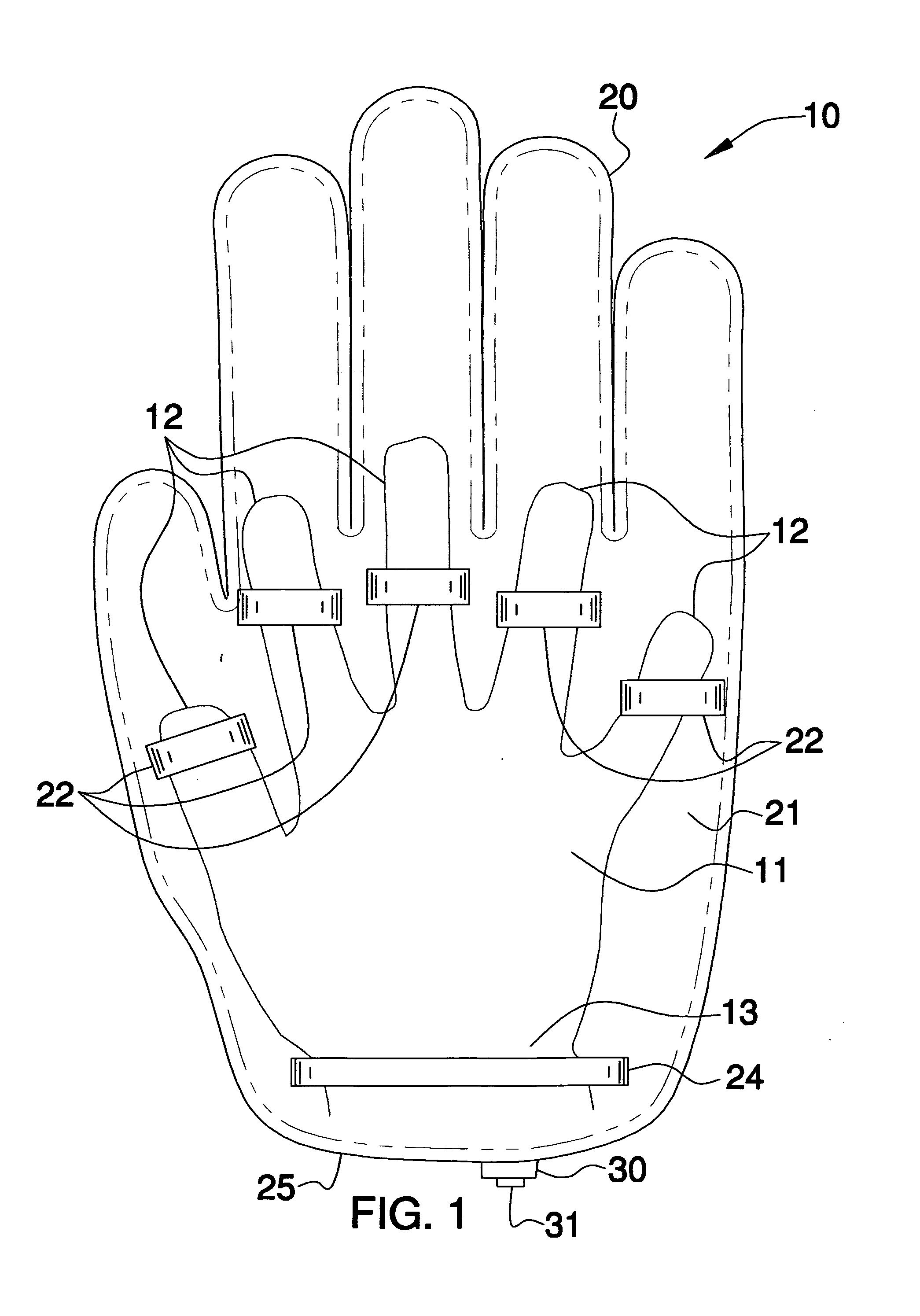

Novelty implements for providing user enjoyment

Hand-operable implements include a plurality of inflatable gloves that are sized and shaped for protruding beyond a user's metacarpals. The gloves are formed from air-impermeable material, have rear sides including a plurality of auxiliary support bands attached thereto, and have substantially smooth and planar front surfaces such that when a user engages the gloves during operating conditions, an elevated acoustic sound is generated therefrom. Each auxiliary support band extends upwardly and away from the rear sides of the gloves. The implements further include a mechanism for allowing a user to selectively inflate the gloves to a desired pressure level such that the user may enjoy use of the gloves during recreational activities as well as fold and store the gloves during non-operating conditions.

Owner:KESSEE RALPH L

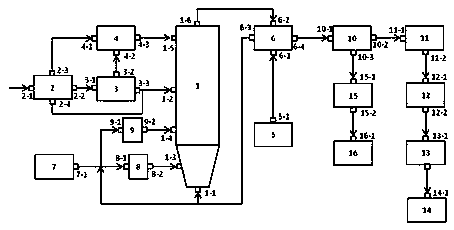

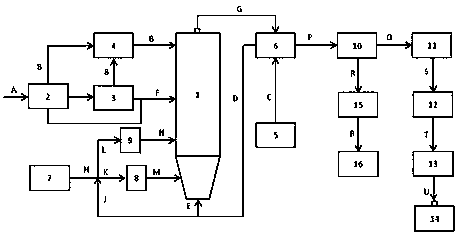

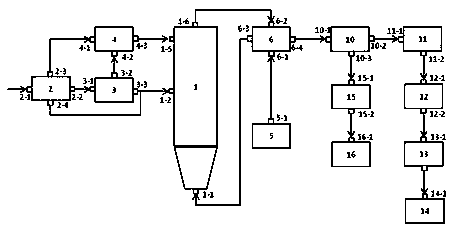

Oil-containing sludge incineration system for pressurized fluidized bed and incineration treatment method

PendingCN110375310AHarmlessAchieve reductionFuel feedersIndirect carbon-dioxide mitigationCombustionHazardous substance

The invention discloses an oil-containing sludge incineration system for a pressurized fluidized bed and an incineration treatment method. The process comprises the following steps: introducing preheated pressurized air into a fluidized bed incinerator, adding oil-containing sludge into the incinerator to pressurize and combust under a fluidized state, and supplementing auxiliary fuels to keep a combustion state stable if combustion heat is insufficient; enabling high-temperature pressurized wet flue gas generated in the incinerator to preheat pressurized air for combustion of the fluidized bed incinerator, preliminarily cooling the pressurized air into medium-temperature pressurized wet flue gas; continuously performing dust-removal denitration treatment on the flue gas to obtain medium-temperature pressurized clean wet flue gas, and recycling separated fly ash; recycling sensible heat of the medium-temperature pressurized clean wet flue gas through a waste heat recycling system, andrealizing up-to-standard emission through treatment such as a follow-up decompression system and a dehumidifying system. Reduction, harmless and resource utilization as well as energy conservation andemission reduction are realized on the oil-containing sludge, so that combustion efficiency can be greatly improved, equipment unit area processing ability is improved, and emission of harmful substances in flue gas is reduced.

Owner:陕西正本环境工程有限公司

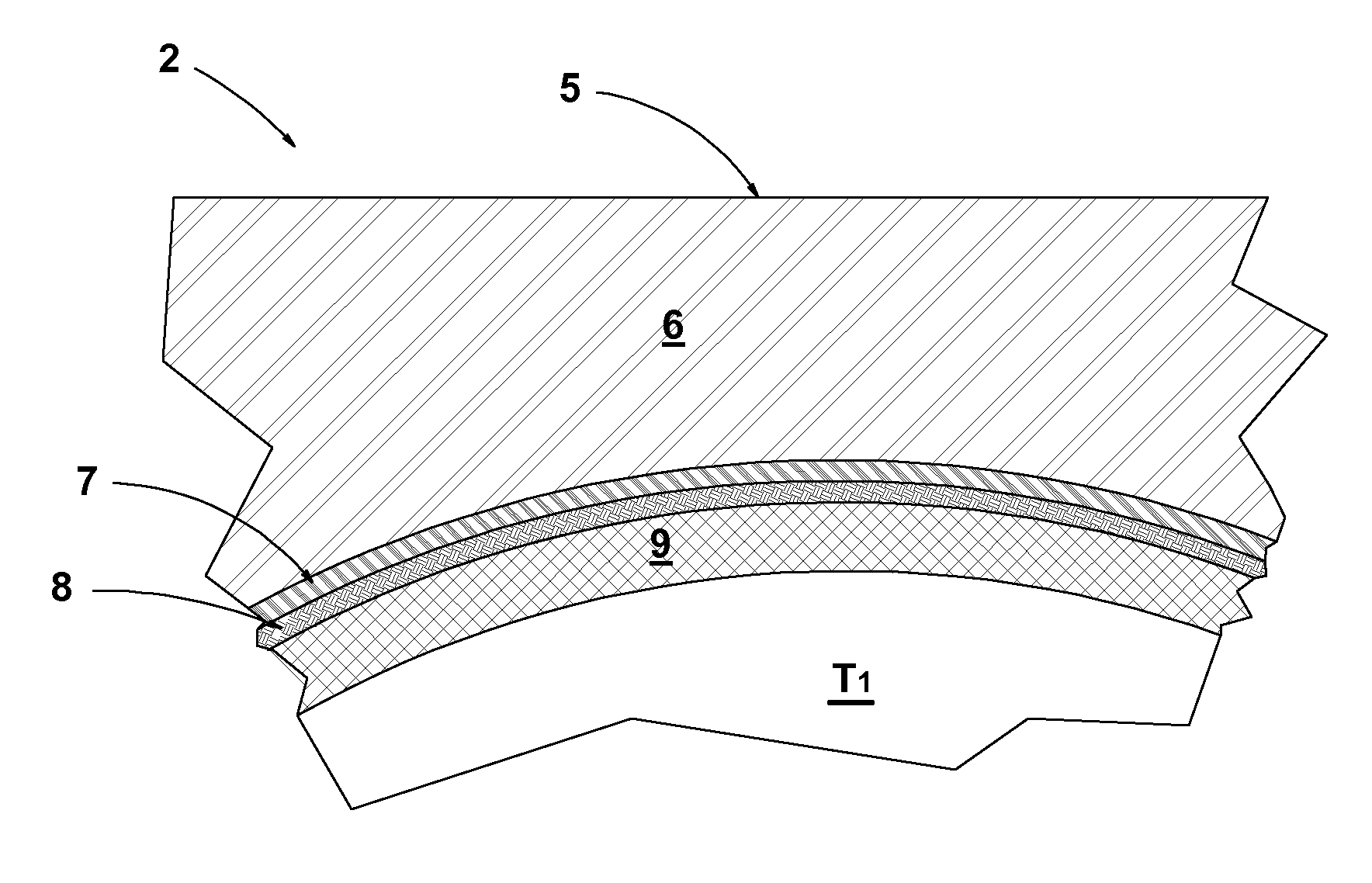

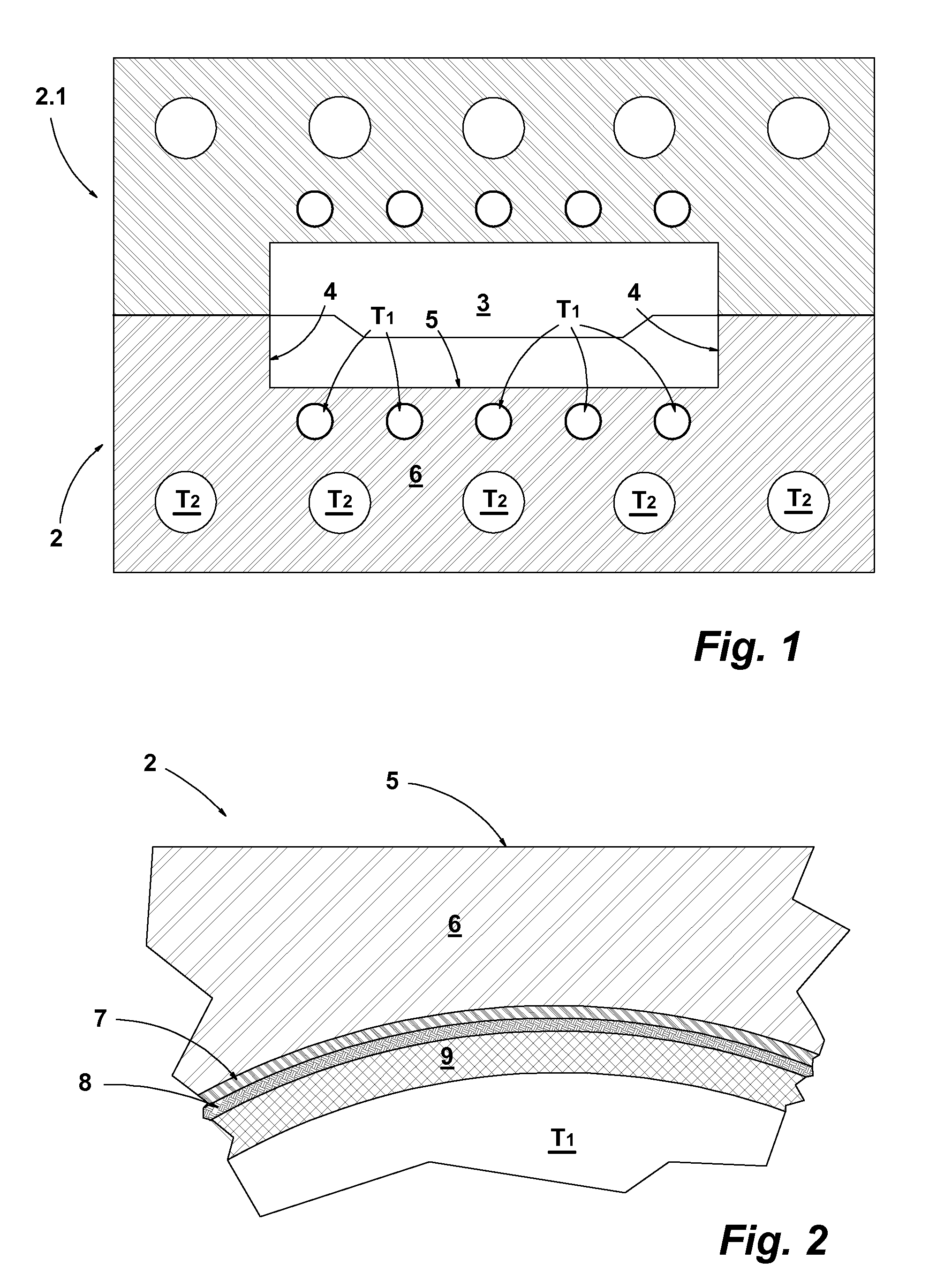

Forming tool

InactiveUS9061445B2Addressing Inadequate ContactShorten cycle timeConfectionerySweetmeatsElectrical conductorInductor

A forming tool, advantageously made from a metal with a forming contact surface (4, 5) and with one or several temperature regulation canals (T1) which are integrated in the tool (2, 2.1) and through which a fluid flows, characterized in that an electric conductor in the form of an inductor (9) is arranged at the internal wall of the temperature regulation canals (T1) and, if need be, with the insertion of a dielectric layer covering the temperature regulation canals (T1).

Owner:ROCTOOL SAS

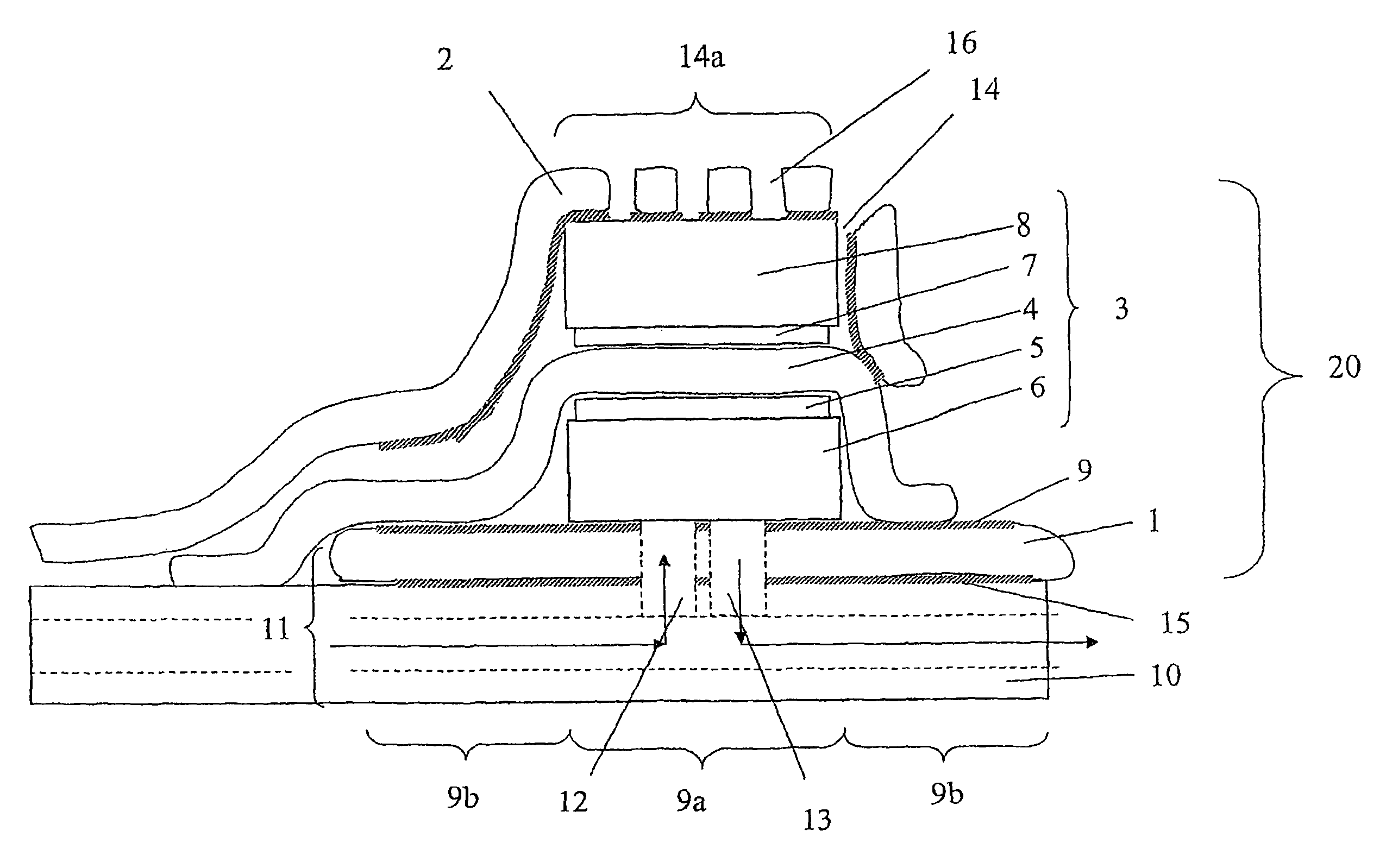

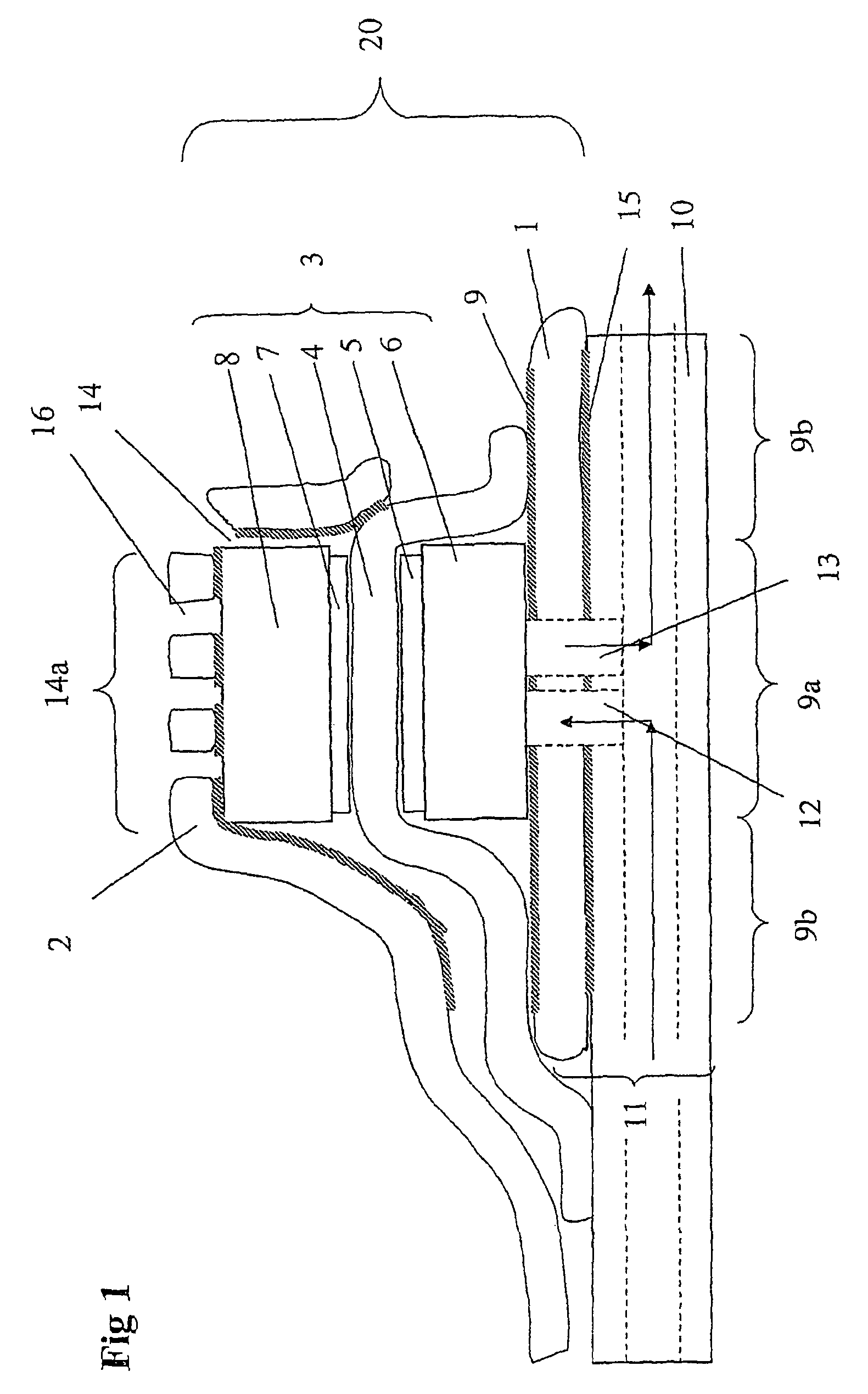

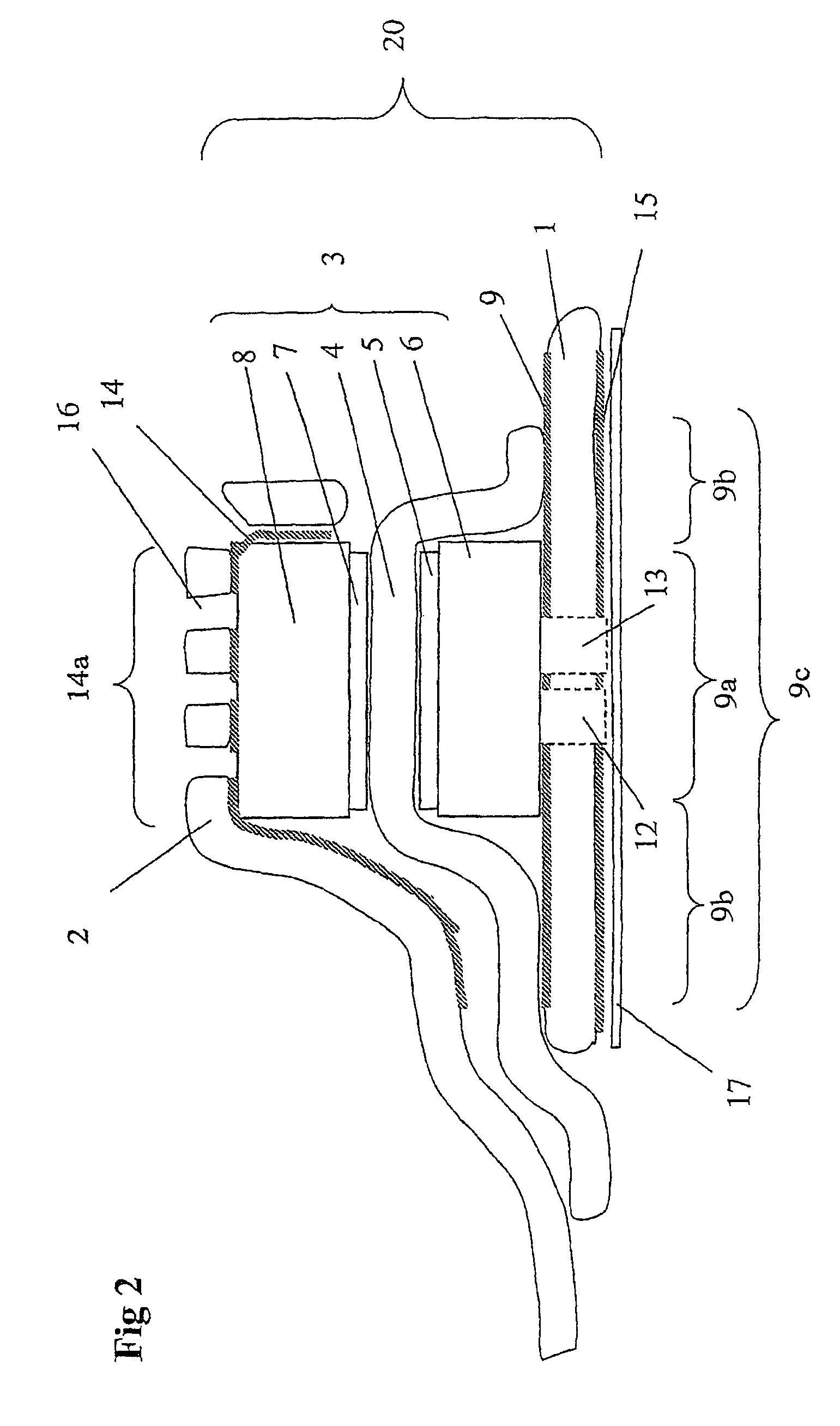

Socket for testing a semiconductor device and a connecting sheet used for the same

InactiveUS20050145842A1Addressing Inadequate ContactIncrease distanceSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceElectricity

Probes 1 for testing and outer connecting terminals 14a are electrically connected to a-test socket for semiconductor devices. In use of a connecting sheet, fabricated by an elastically deformative insulating member and electrodes 202, flexibility is given, and good electrical contacts are obtainable. Further, because the connecting sheet 2 is exchangeable, contacting capability is recovered by exchange when solder debris is adhered and deposited to increase contact resistances. Accordingly, even though there is scattering of the heights of the outer connecting terminals, good electrical contact with the probes is obtainable, and even though the solder debris of the outer connecting terminals is adhered and deposited as a result of repeated usage, tests can be continuously conducted, wherein the test socket for semiconductor devices has good maintenance capability.

Owner:MITSUBISHI ELECTRIC CORP

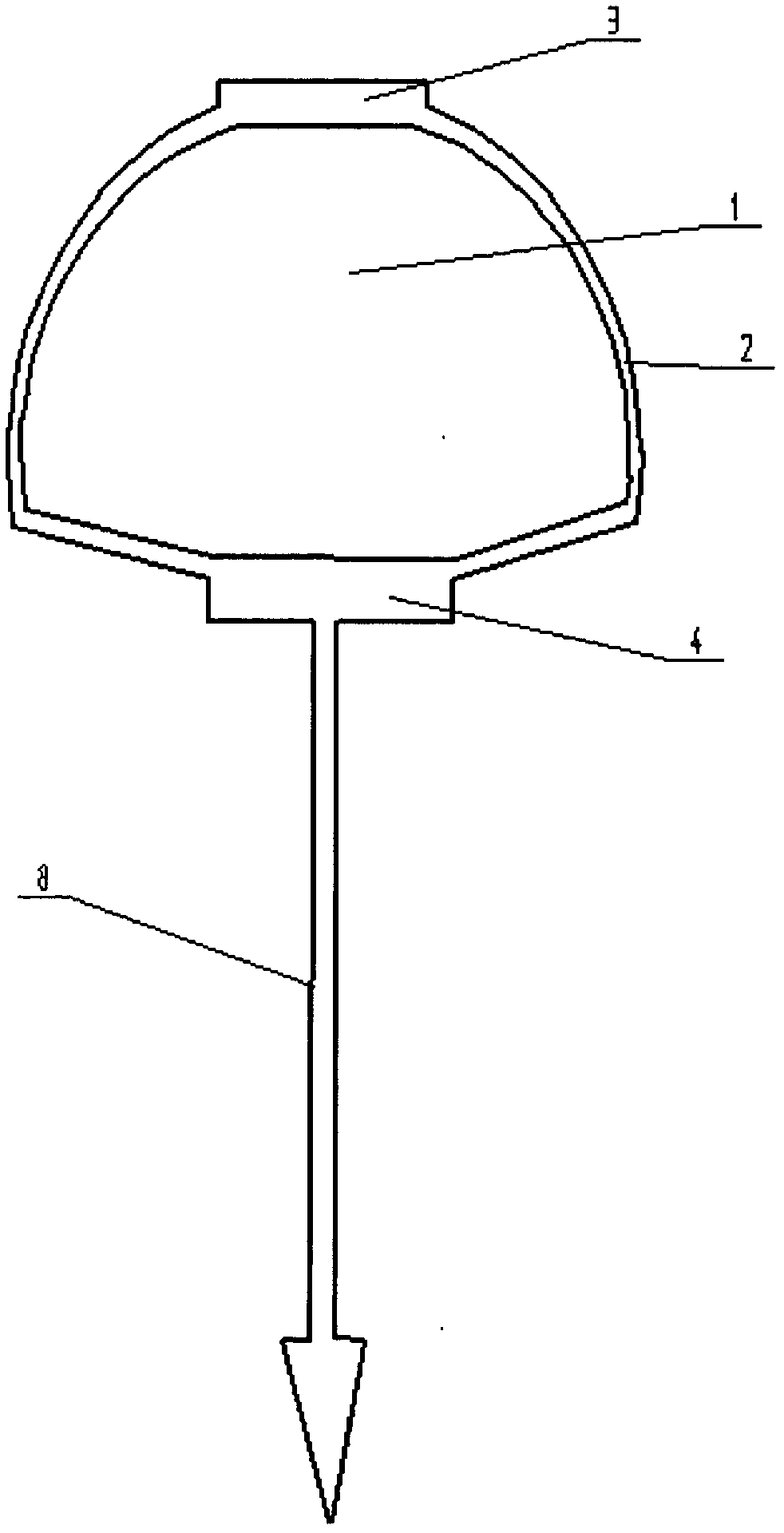

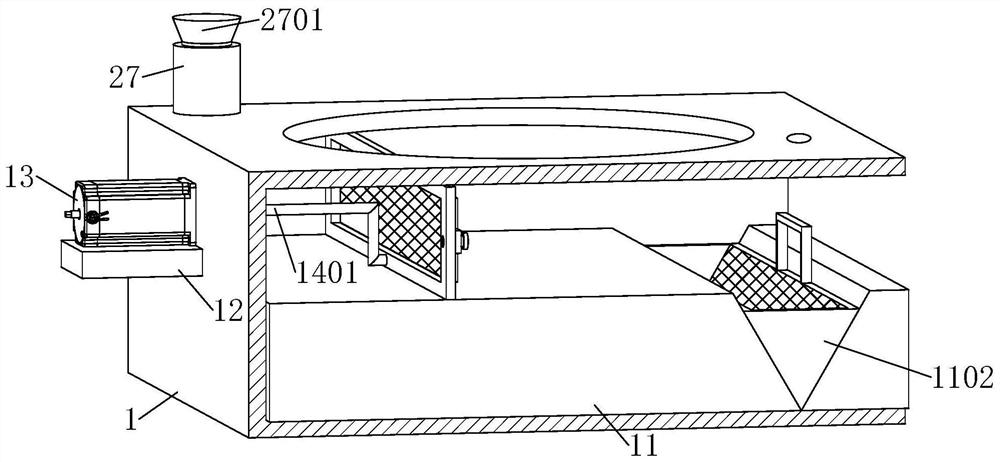

Undisturbed soil sample sealing device based on a wax sealing method and sealing method thereof

The invention discloses an undisturbed soil sample sealing device based on a wax sealing method and a sealing method thereof, and relates to the technical field of soil sample collection. The undisturbed soil sample sealing device based on the wax sealing method comprises a soil sample placer, circular hollow partition plates, inner pipe sleeves and a long-neck funnel, wherein the soil sample placer is composed of two layers of materials, a plurality of inner pipe sleeves and a plurality of circular hollow partition plates are arranged in the soil sample placer, an undisturbed soil sample is placed in the inner pipe sleeves, liquid paraffin is injected into the soil sample placer through the long-neck funnel, and the undisturbed soil sample is poured and sealed. The undisturbed soil samplesealing device has the advantages of being higher in sealing performance on irregular soil samples, higher in protectiveness on soil samples difficult to form, tighter in fitting with the inner wallof the sealing device and the like, and the problems that an existing soil sample sealing device is poor in sealing performance, low in protection performance, high in requirement for the size of thesoil samples, single in size of the soil samples suitable for each specification and the like are solved.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

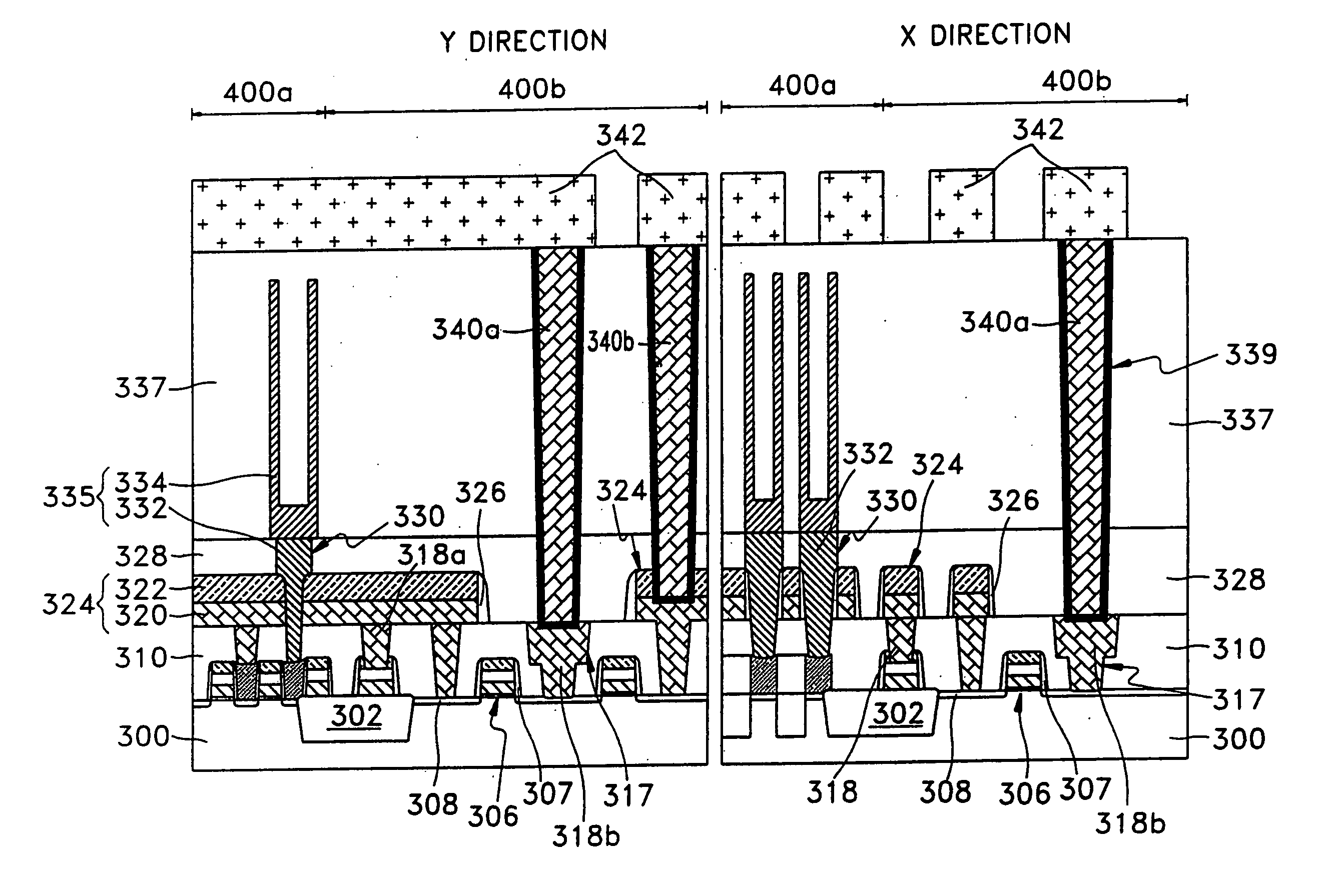

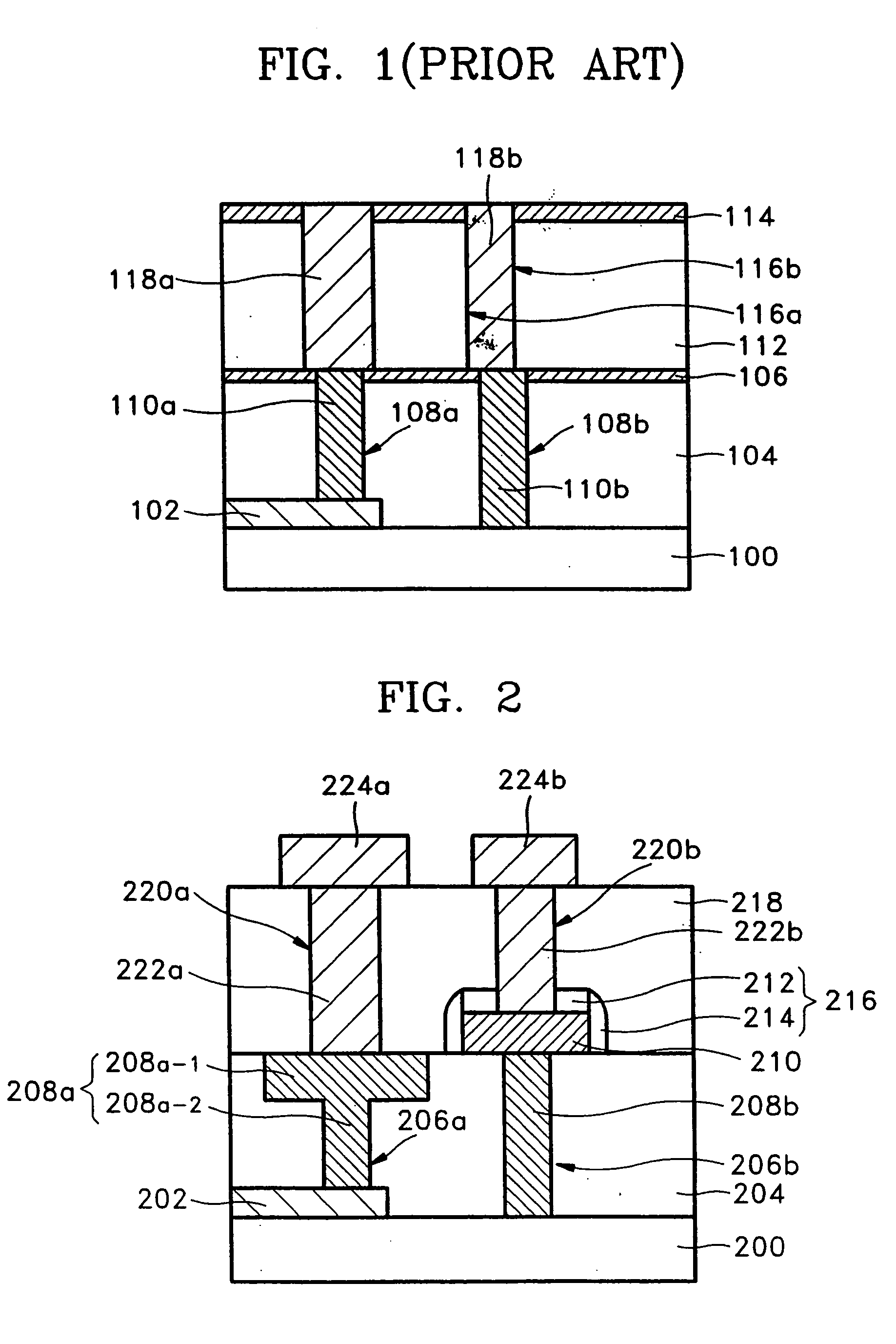

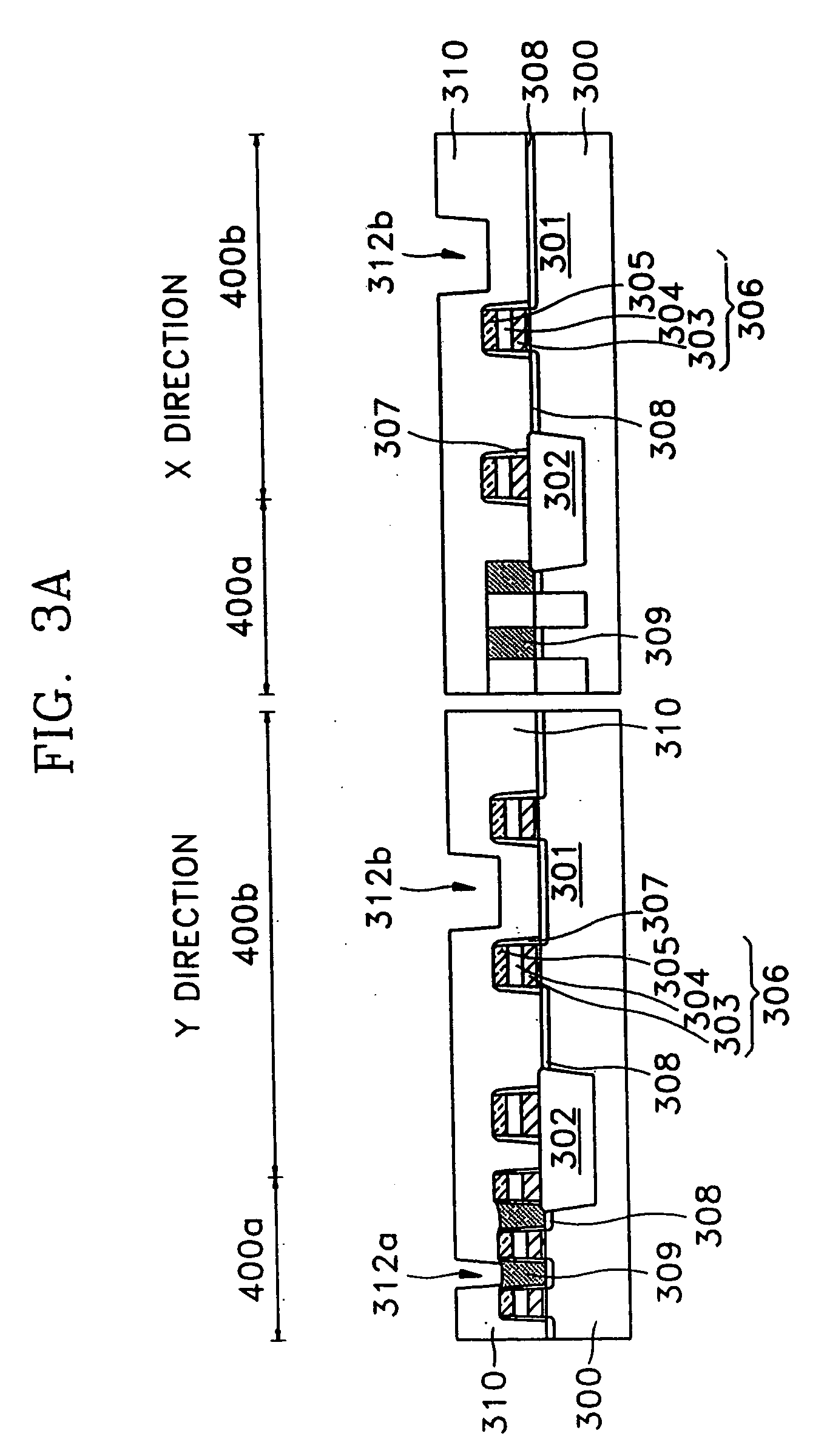

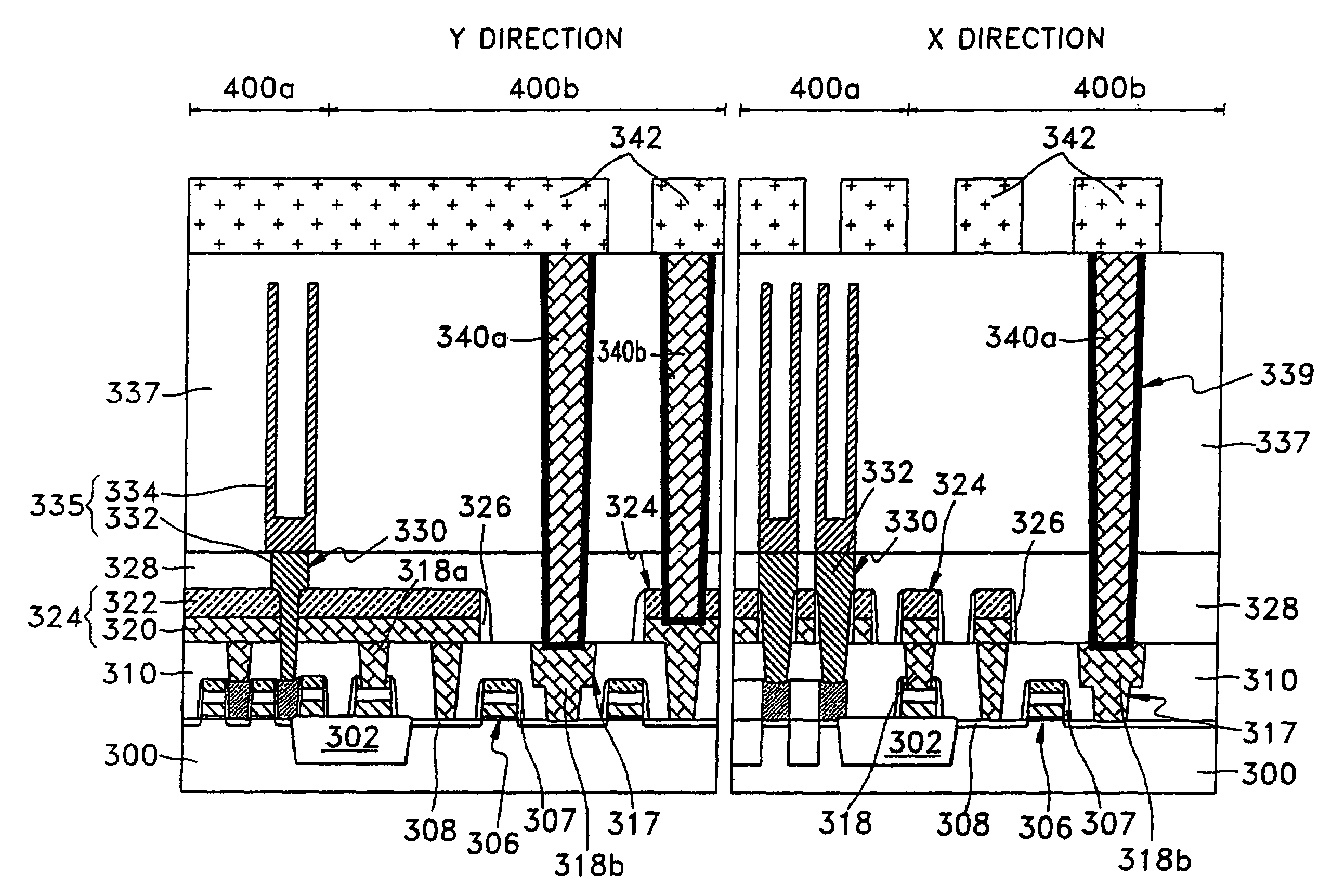

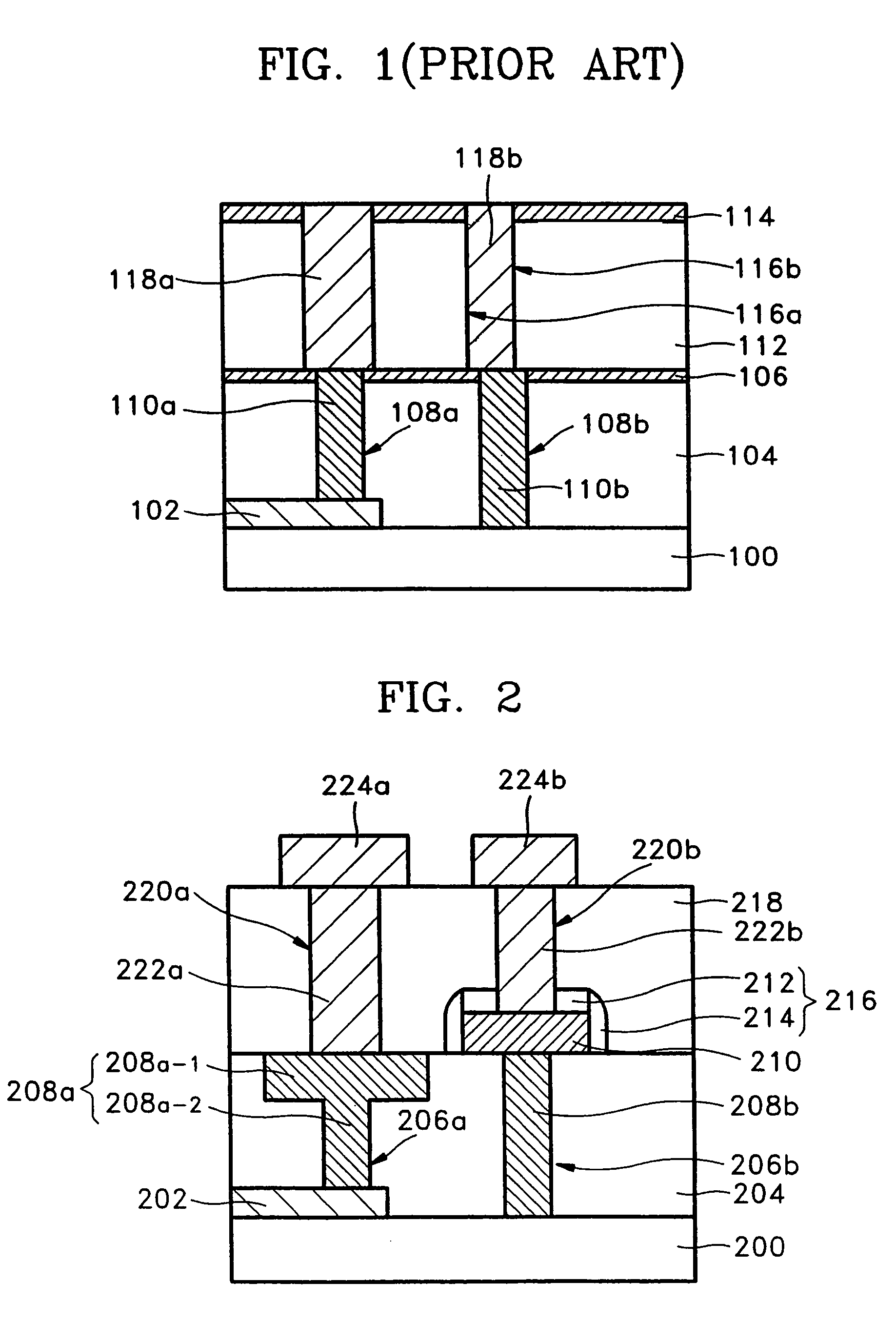

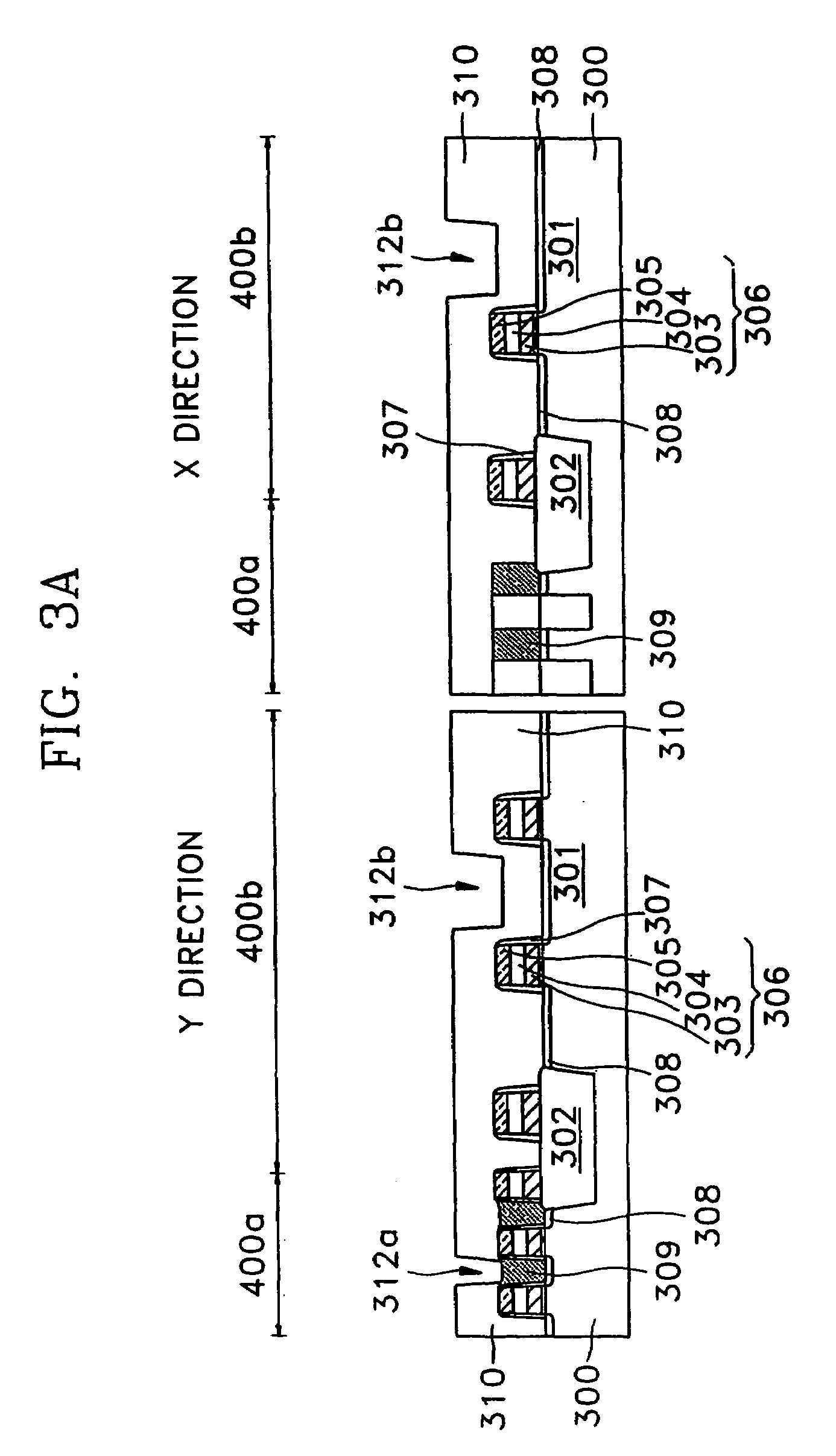

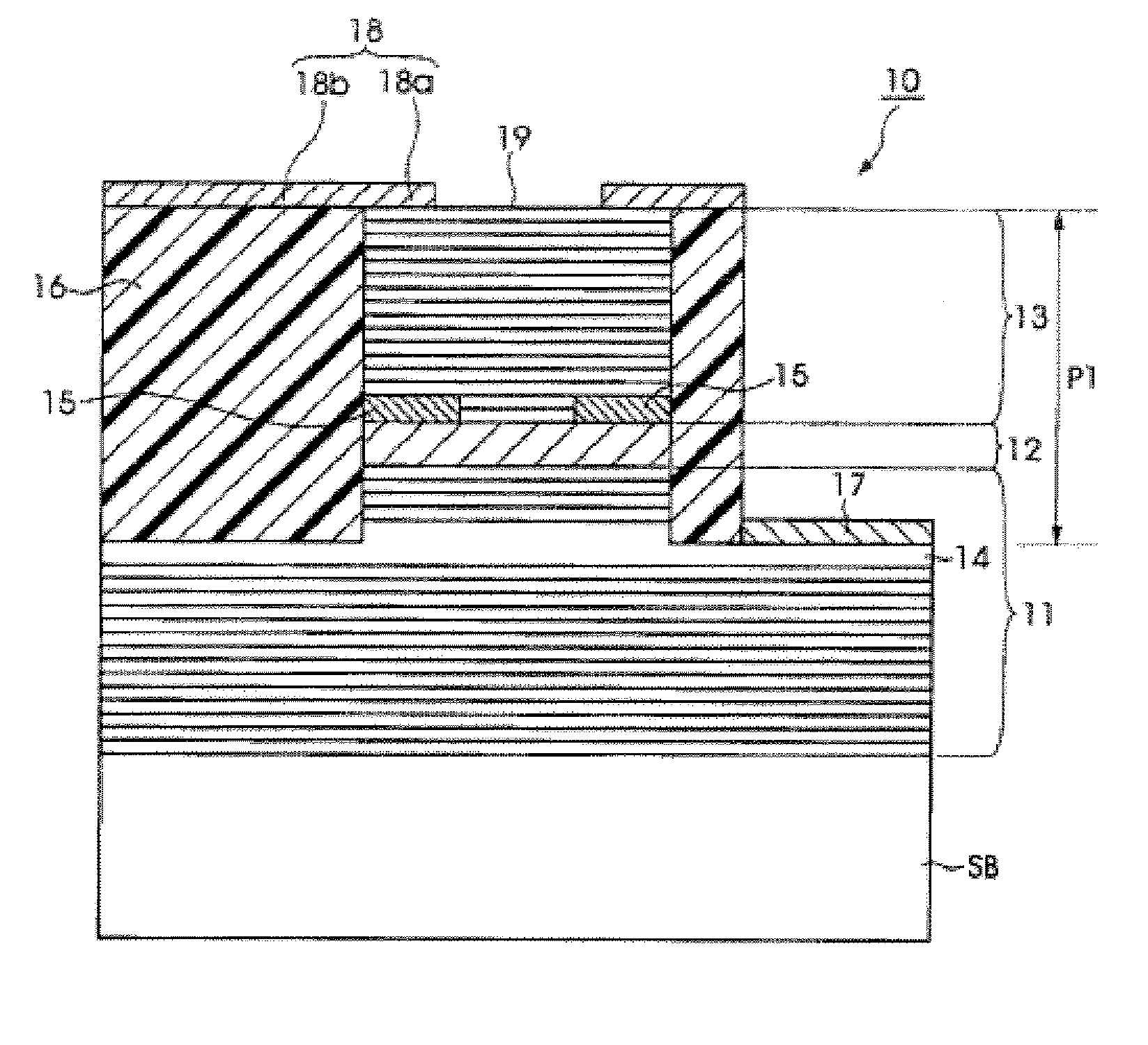

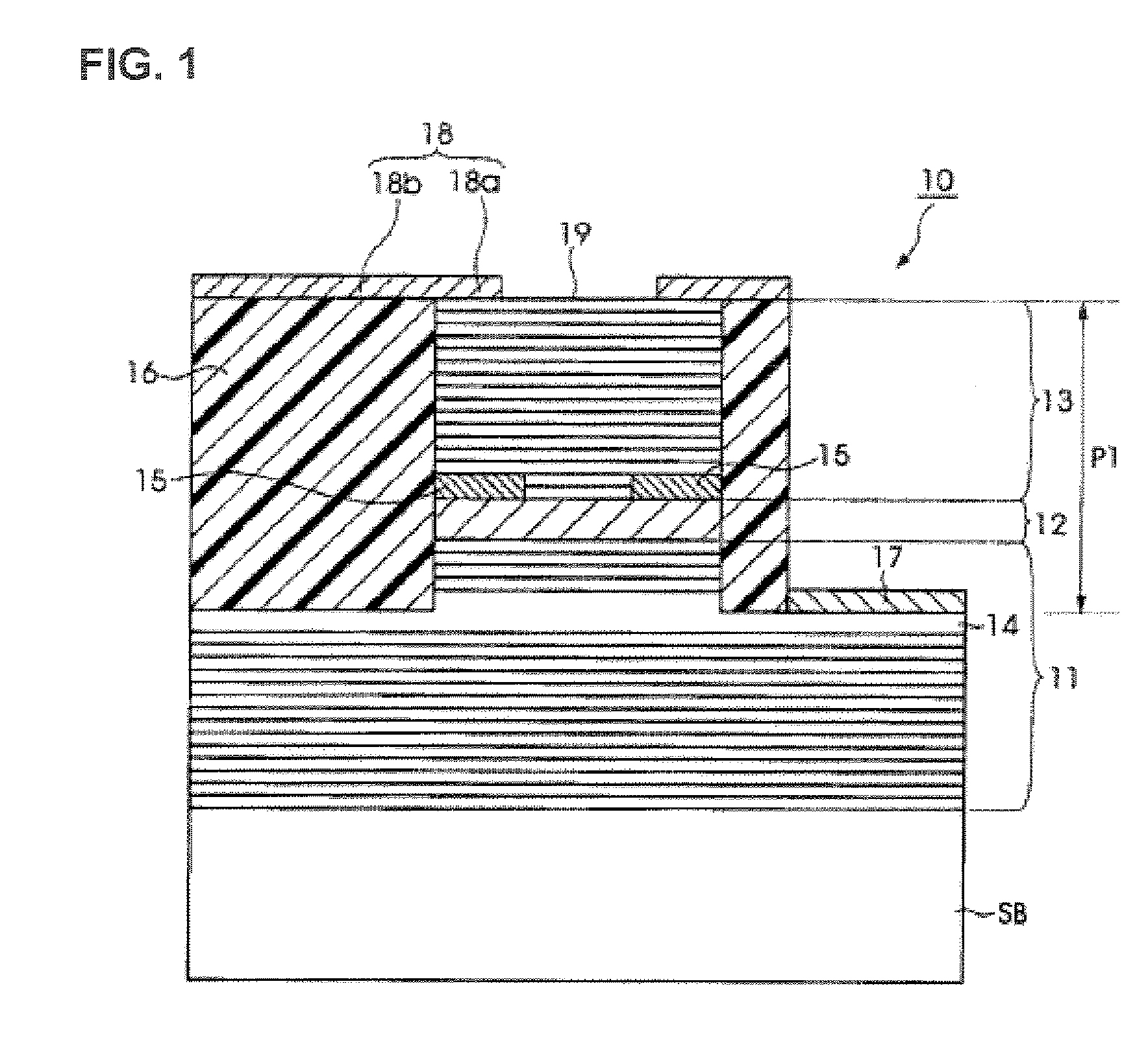

Semiconductor device having multilayer interconnection structure and manufacturing method thereof

InactiveUS20050070094A1Prevent short-circuitsRelieve pressureTransistorSemiconductor/solid-state device detailsDielectricDevice material

A semiconductor device and manufacturing method thereof include a semiconductor substrate, an interlevel dielectric (ILD) layer formed on the semiconductor substrate, a first contact stud formed in the ILD layer, having a width of an entrance portion adjacent to the surface of the ILD layer larger than the width of a contacting portion adjacent to the semiconductor substrate, and a second contact stud spaced apart from the first contact stud and formed in the ILD layer. The semiconductor device further includes a landing pad formed on the ILD layer to contact the surface of the second contact stud, having a width larger than that of the second contact stud. The second contact stud has a width of a contacting portion that is the same as that of an entrance portion. Also, at least one spacer comprising an etch stopper material is formed on the sidewalls of the landing pad and the etch stopper is formed on the landing pad. The entrance portion of the first contact stud has a width about 30-60% larger than that of the contacting portion.

Owner:SAMSUNG ELECTRONICS CO LTD

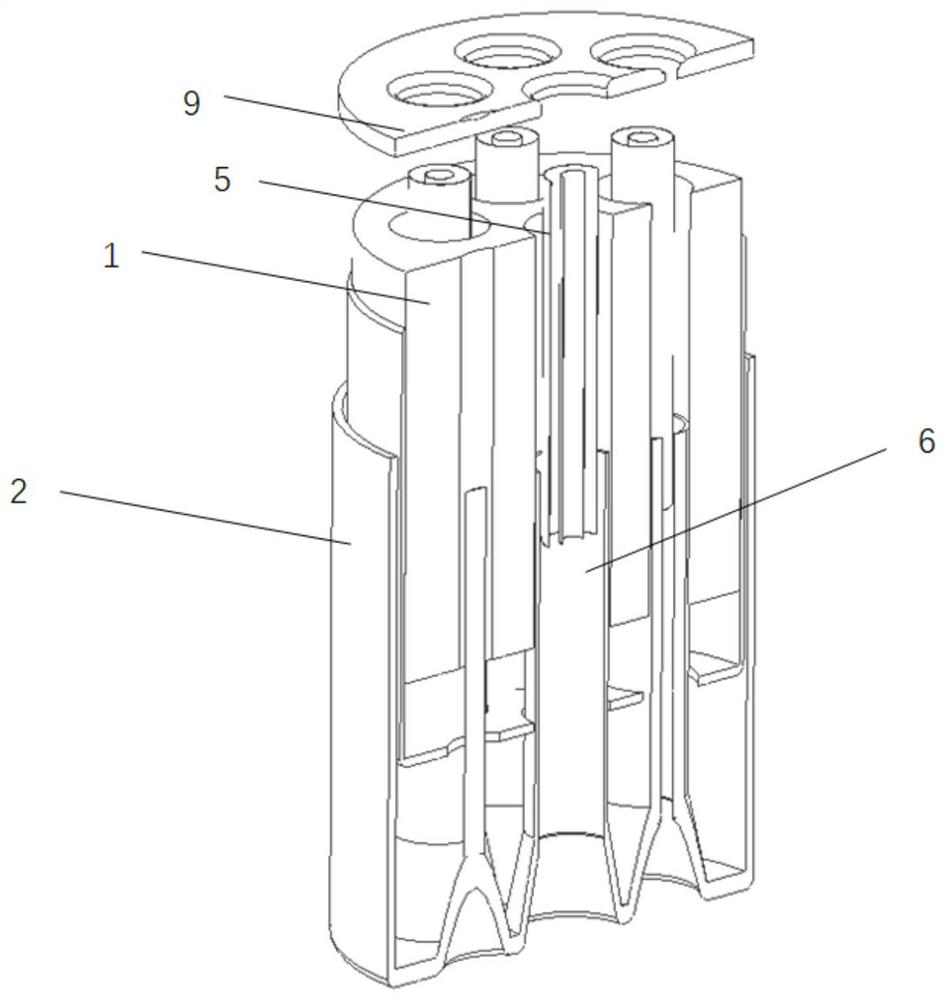

Air water taking device based on chimney effect

ActiveCN112982566AImprove efficiencyReduce pressureDrinking water installationEngineeringEnvironmental geology

The invention relates to an air water taking device based on a chimney effect. The air water taking device comprises a water taking box body, wherein a secondary water collecting device is arranged at the top of the water taking box body, and a water collecting box is arranged at the bottom of the water taking box body; the secondary water collecting device is fixed at the top of the water taking box body through brackets which are distributed at equal intervals in the circumferential direction; the water taking box body is fixed on the water collecting box through a plurality of upright posts; the water taking box body comprises a shell; a heat insulating layer is arranged in the shell; the heat insulating layer and the shell are coaxially arranged; a plurality of uniformly distributed ventilation pipelines are arranged in the heat insulating layer; the ventilation pipelines are cylindrical; a primary water collecting device is arranged on the inner surface of each ventilation pipeline; the outer surface of each ventilation pipeline is coated with a phase change material; and the top and the bottom of each ventilation pipeline communicate with the atmosphere respectively. According to the air water taking device, the characteristics of heat absorption and heat release of the phase change energy storage material under the influence of day and night temperature difference are utilized, the chimney effect is combined to directionally drain air with higher humidity, and a special water collecting sail is utilized to effectively extract moisture in the air.

Owner:WUHAN UNIV OF TECH

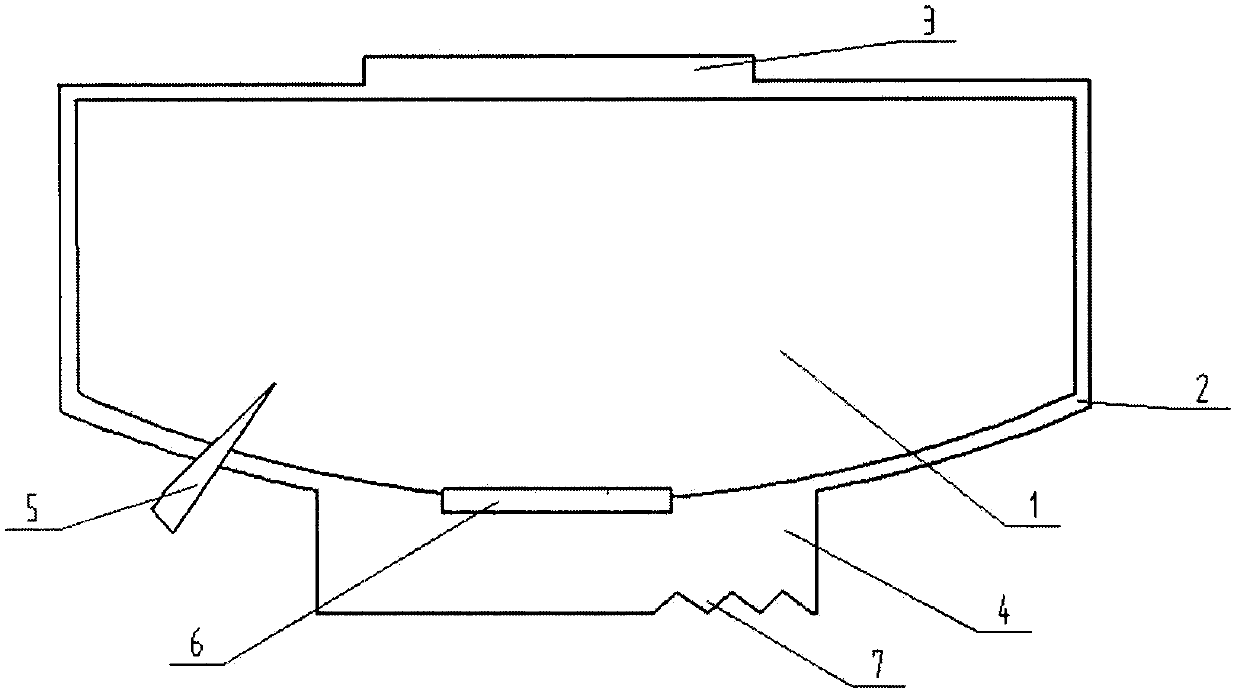

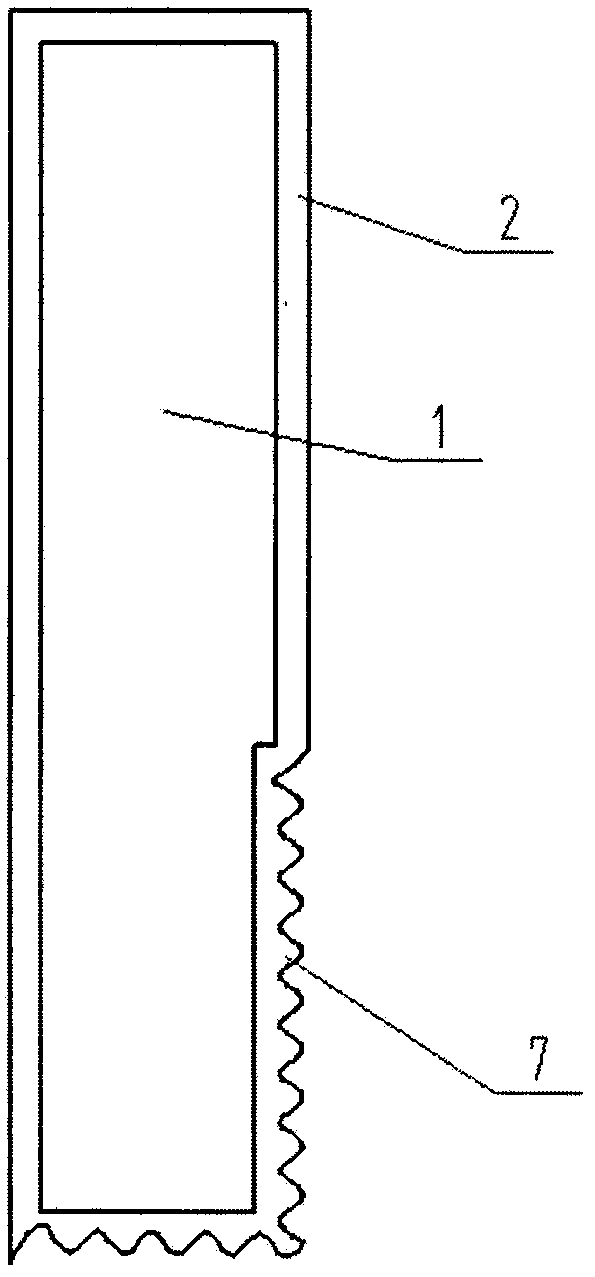

Plane-coated formed condom

The invention provides a plane-coated formed condom. A reinforcing block (4) is arranged at the lower end of a body (1), a reinforcing strip (3) is arranged at the upper end of the body (1), the outeredge of the body (1) is coated with glue (2), the surfaces of the reinforcing strip (3) and the reinforcing block (4) are coated with the glue (2), a positioning element (6) is arranged at the connected part of the reinforcing block and the body, an automatic sealing strip (5) is arranged at the edge of the body (1), and the surface coated with the glue (2) is covered with a layer of detachable paper film.

Owner:卓之洲

Semiconductor device having multilayer interconnection structure and manufacturing method thereof

InactiveUS7510963B2Prevent short-circuitsAddressing Inadequate ContactTransistorSemiconductor/solid-state device detailsDielectricDevice material

A semiconductor device and manufacturing method thereof include a semiconductor substrate, an interlevel dielectric (ILD) layer formed on the semiconductor substrate, a first contact stud formed in the ILD layer, having a width of an entrance portion adjacent to the surface of the ILD layer larger than the width of a contacting portion adjacent to the semiconductor substrate, and a second contact stud spaced apart from the first contact stud and formed in the ILD layer. The semiconductor device further includes a landing pad formed on the ILD layer to contact the surface of the second contact stud, having a width larger than that of the second contact stud. The second contact stud has a width of a contacting portion that is the same as that of an entrance portion. Also, at least one spacer comprising an etch stopper material is formed on the sidewalls of the landing pad and the etch stopper is formed on the landing pad. The entrance portion of the first contact stud has a width about 30-60% larger than that of the contacting portion.

Owner:SAMSUNG ELECTRONICS CO LTD

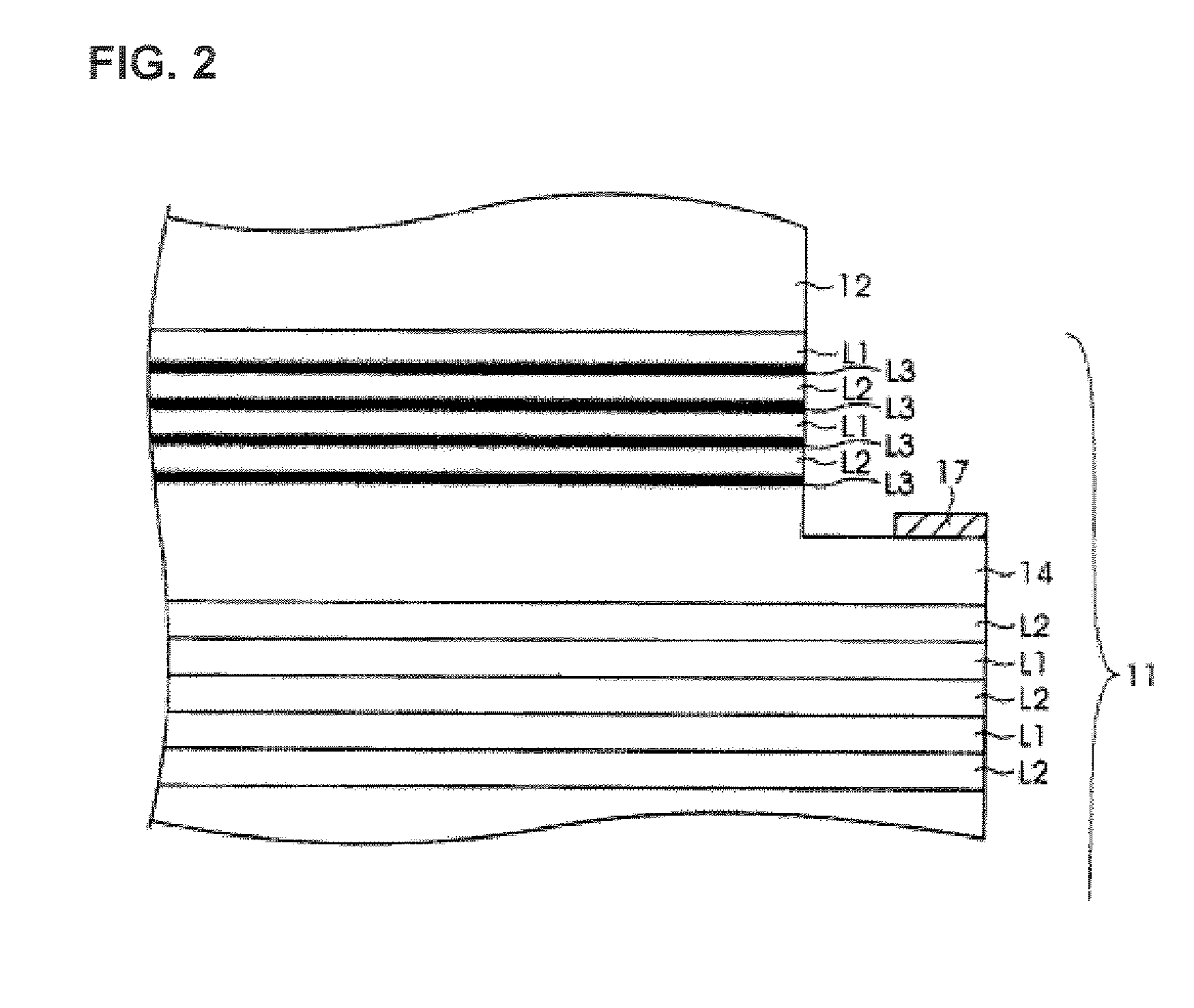

Surface-emitting type semiconductor laser and method for manufacturing the same

InactiveUS20070096122A1Lower resistanceSufficient ohmic contactLaser detailsSolid-state devicesElectrical conductorRefractive index

A surface-emitting type semiconductor laser includes: an upper mirror and a lower mirror each composed of alternately formed first semiconductor layers and second semiconductor layers; an active layer disposed between the upper mirror and the lower mirror, wherein the surface-emitting laser emits laser light in a direction in which the first semiconductor layers and the second semiconductor layers are formed; a thick film layer formed with one of the first semiconductor layers composing the lower mirror, the thick film layer being thicker than other of the first semiconductor layers; and a third semiconductor layer provided between the thick film layer and one of the second semiconductor layers on the thick film layer, the third semiconductor layer having a refractive index between a refractive index of the first conductive layer and a refractive index of the second semiconductor layer.

Owner:SEIKO EPSON CORP

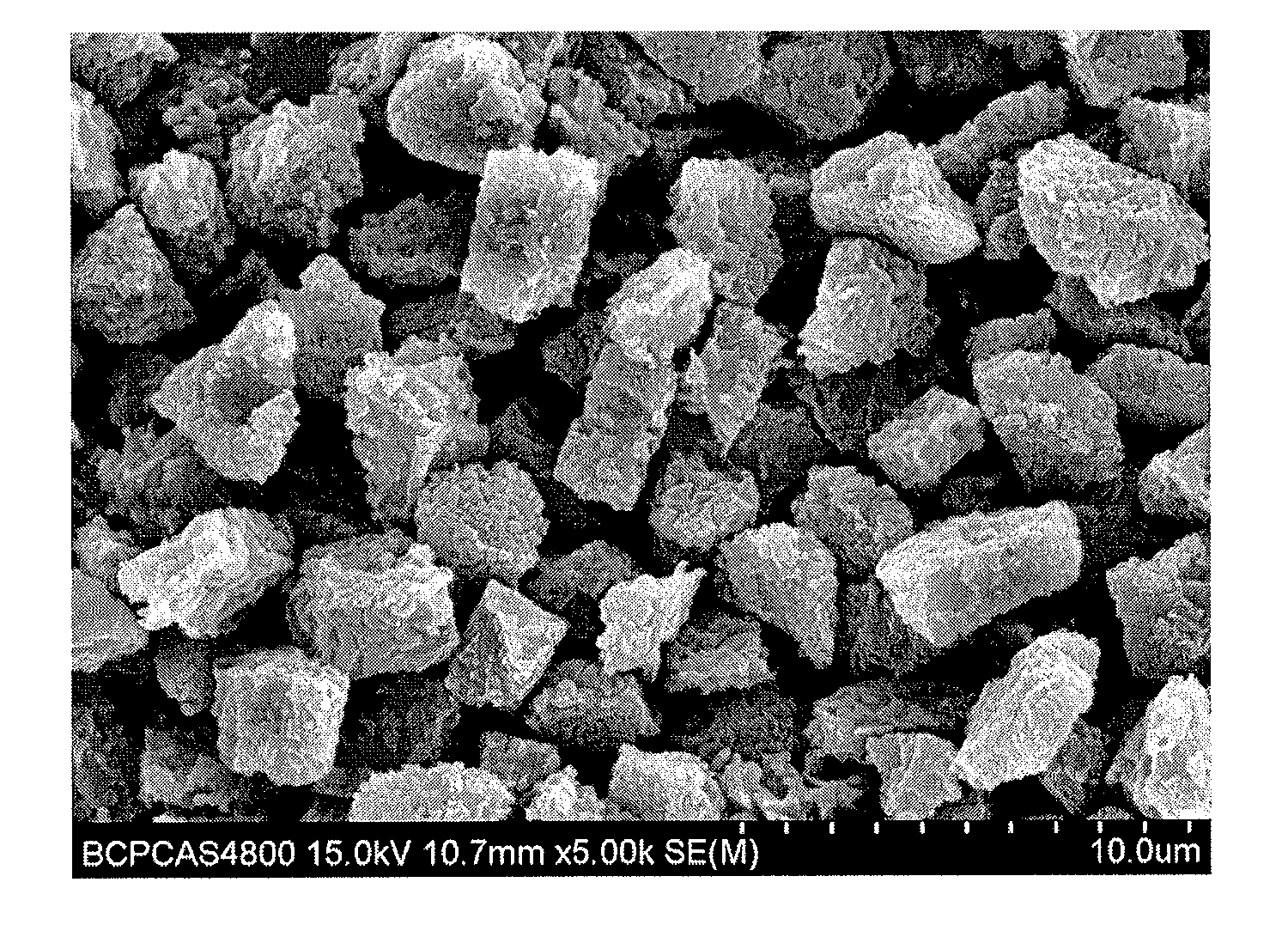

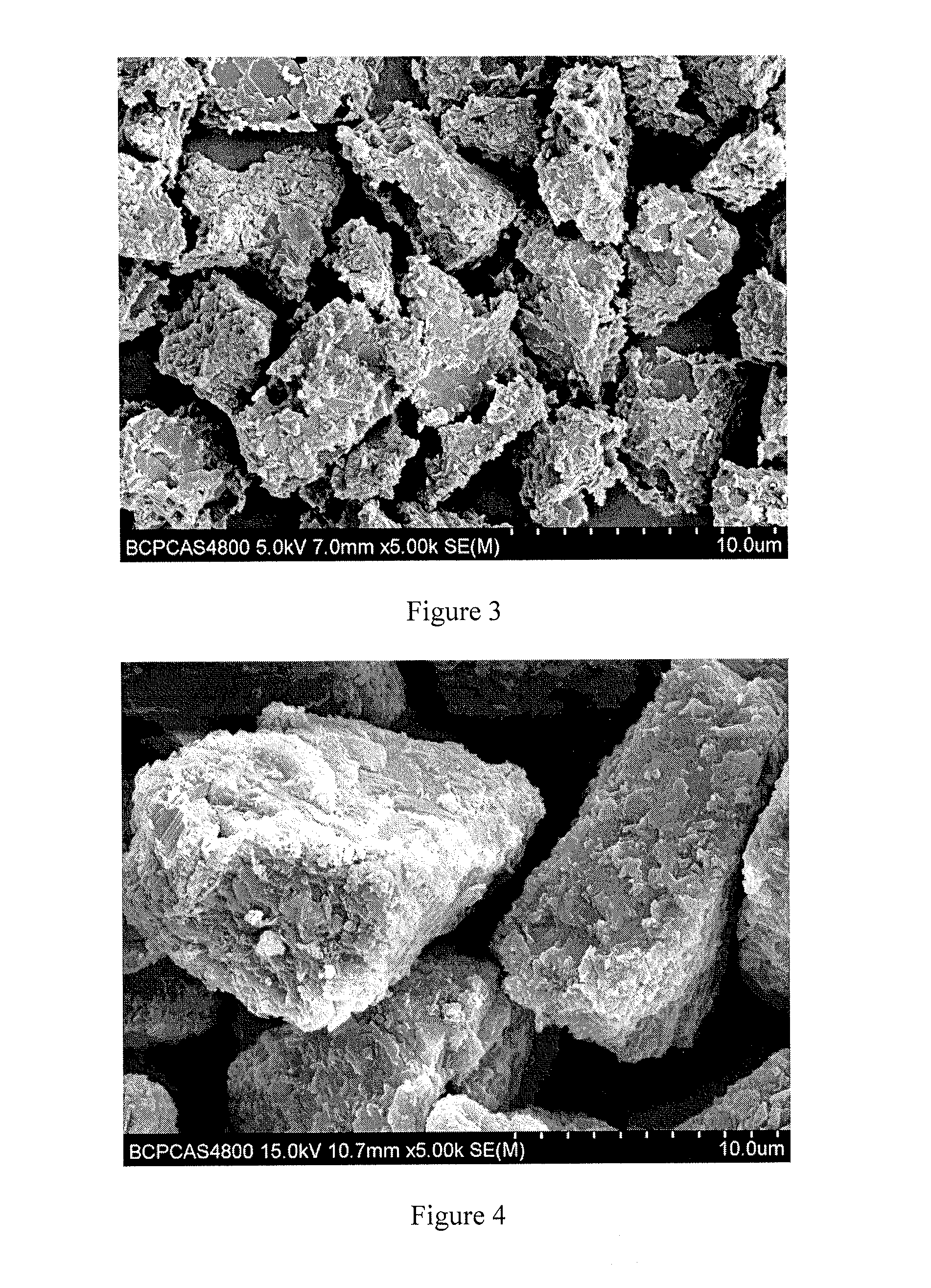

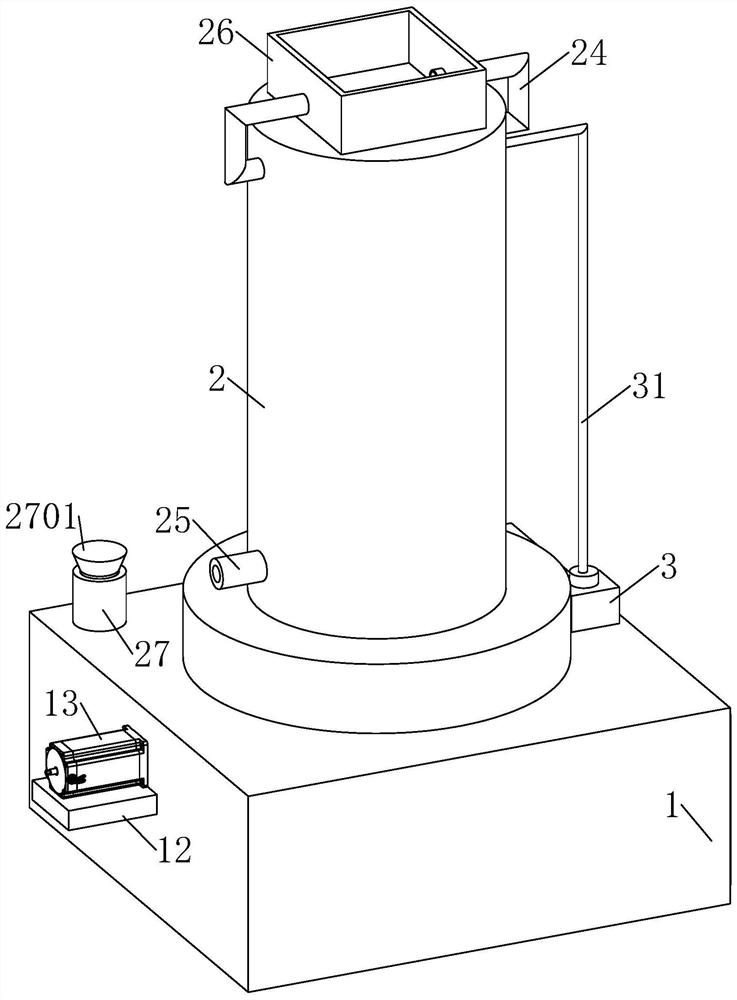

A method of preparing a monocrystalline diamond abrasive grain

ActiveUS20160281264A1Large pitFew pointPolycrystalline material growthAfter-treatment detailsRough surfaceMicron scale

The present invention relates to method of preparing a monocrystalline diamond abrasive grain comprising the steps of: sufficiently dispersing a micron-scale monocrystalline diamond and at least a micron-scale metal powder in a sol containing at least a nano-scale metal powder, and controlling the suitable ratio of the two kinds of metal powder with different order of magnitude of particle size, accordingly the micron-scale metal powder can be stuffed into voids among the monocrystalline diamond grains, and only a suitable amount of nano-scale metal powder is required to let the micron-scale metal powder and nano-scale metal powder coat together on the surface of the micron-scale diamond to form an integral and uniform coating layer including at least two kinds of metal grains, thus the resulting monocrystalline diamond abrasive grains have a unique rough-surface morphology, a plurality of contact points and contact surfaces resenting in the grinding process and good self-sharpening.

Owner:BEIJING POLYSTAR HITECH CO LTD

Double-loop flue gas desulfurization tower

PendingCN113457412AEasy to disassembleSolve the problem that manual cleaning is labor-intensive and difficult to concentrateGas treatmentDispersed particle filtrationThermodynamicsEngineering

The invention relates to the technical field of flue gas desulfurization, and concretely relates to a double-loop flue gas desulfurization tower. The tower comprises a solution box, the upper surface of the solution box is fixedly connected with a tower body and a water pump, the water inlet end of the water pump is fixedly connected with a liquid inlet pipe, and the water outlet end of the water pump is fixedly connected with a liquid outlet pipe. A spraying device is fixedly connected to the inner top wall of the tower body, a filtering device is fixed to the inner wall of the tower body, a brushing device is slidably connected to the surface of the filtering device, and the brushing device is rotatably connected with the spraying device through a double-crank sliding block mechanism. According to the double-loop flue gas desulfurization tower, an electric push rod is arranged to conveniently drive a right-angle rod to move rightwards, the right-angle rod conveniently drives a concentric-square-shaped frame to move rightwards, and then a filter screen is driven to push rightwards, so that sediments such as gypsum fall into a funnel, and impurities such as gypsum are conveniently taken out by the funnel and then are treated in a centralized manner; therefore, the problems that more impurities such as gypsum are generated during industrial flue gas desulfurization, the labor intensity of manual cleaning is high, and centralized treatment is difficult are solved.

Owner:王玉祥

Method for producing dephenolized cottonseed protein

InactiveCN111018944AAddressing Inadequate ContactImprove efficiencyPeptide preparation methodsProcess engineeringMethanol

The invention relates to a method for producing dephenolized cottonseed protein. The method comprises the following steps: 1, putting cottonseed kernels into a cottonseed kernel sieve, and sieving thecottonseed kernels to obtain large kernels and fine powder; 2, softening and pressing the large kernels screened in the step 1 into blanks, extruding and puffing the fine powder, and carrying out moisture regulation by using a flat-plate drying machine; 3, conveying the material modulated by the flat-plate drying machine in the step 2 to a degreasing extractor, and carrying out countercurrent extraction; 4, conveying the material treated in the step 3 into a dephenolization extractor, and carrying out countercurrent extraction by using alkaline methanol; 5, spraying acidic methanol to the material treated by the dephenolization extractor in the step 4; 6, detecting the pH value of the material treated in the step 5, and conveying the material to a horizontal spiral discharge centrifuge for centrifugal treatment when the material is neutral; and 7, putting a material separated by centrifugal treatment in the step 6 into an evapo-separated machine for low-temperature drying to obtain the dephenolized cottonseed protein. The method provided by the invention has the effects of low energy consumption, less protein denaturation and simultaneous removal of gossypol and aflatoxin.

Owner:CHENGUANG BIOTECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com