Graphene/nitrogen doped carbon/nickel/nickel oxide composite material preparation method

A nitrogen-doped carbon, composite material technology, applied in the manufacture of hybrid/electric double layer capacitors, nanotechnology for materials and surface science, hybrid capacitor electrodes, etc., can solve the problem of many process preparation steps and low specific capacitance of composites , time-consuming and other problems, to achieve the effect of broad application prospects, high specific capacitance, and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

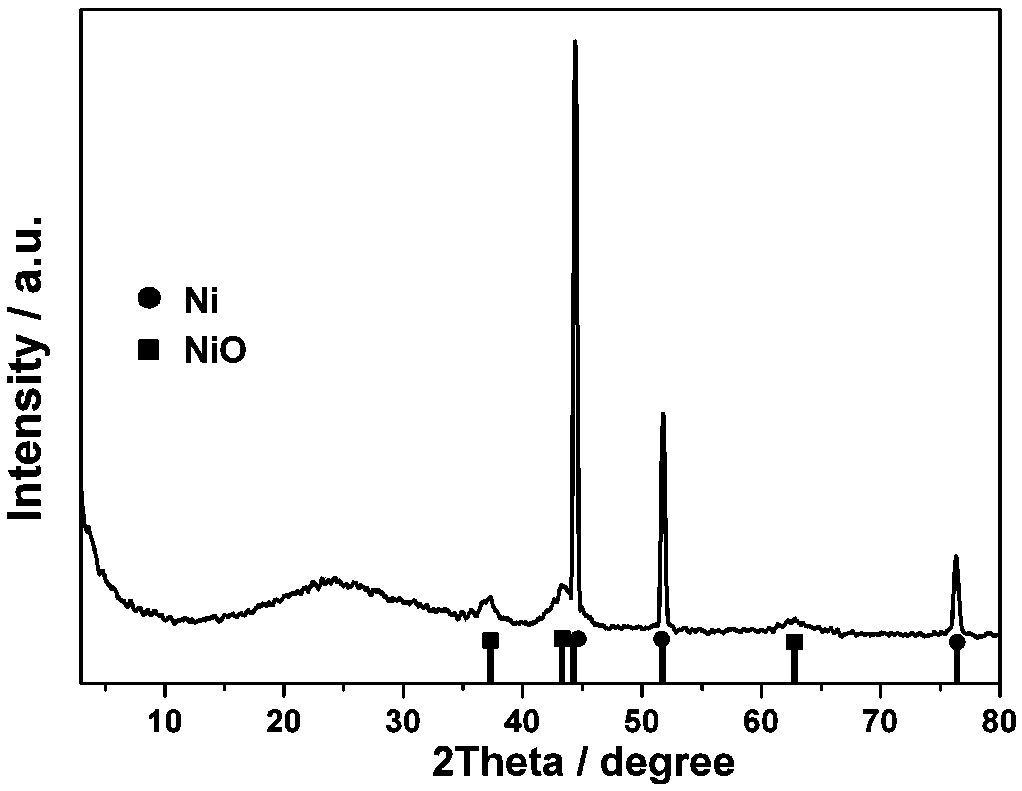

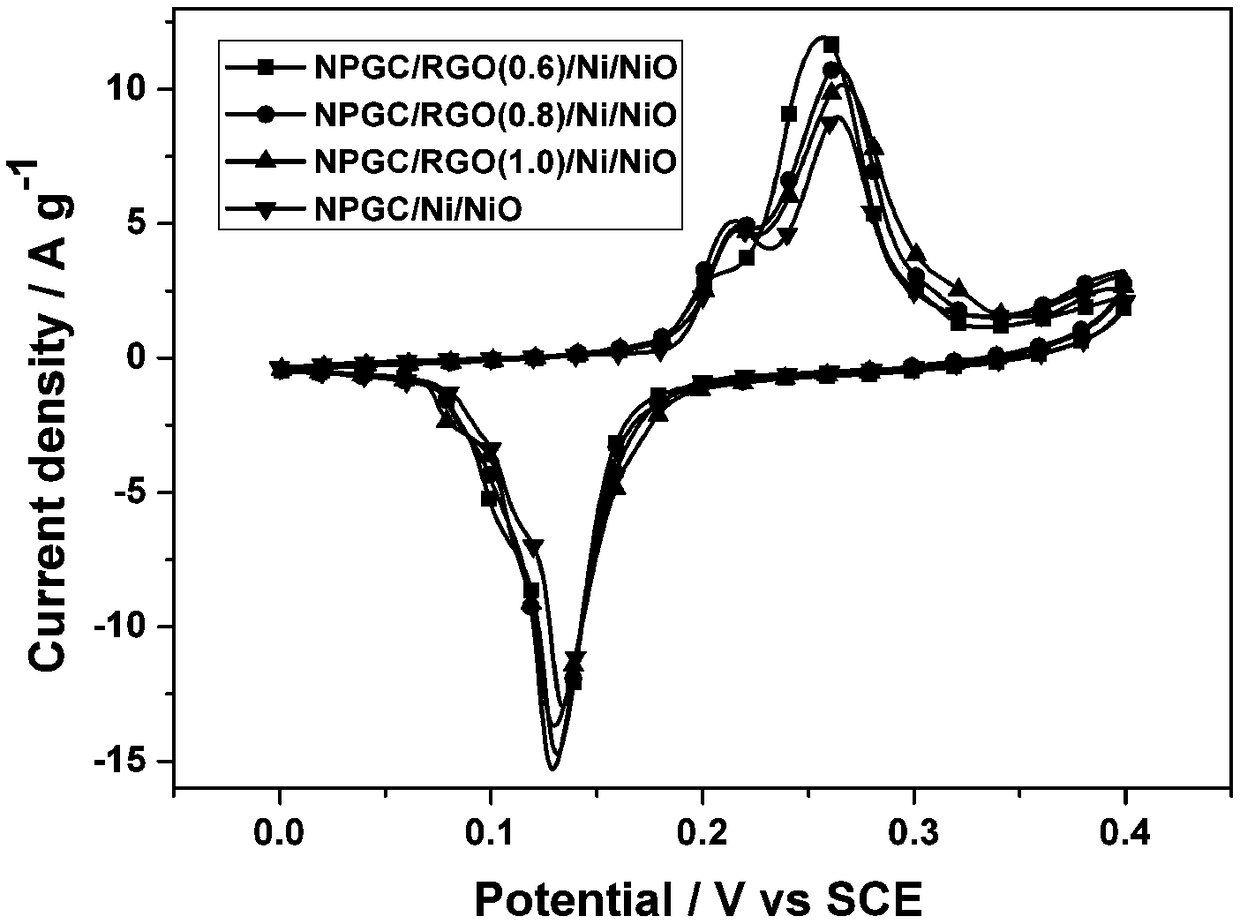

[0030] Get 30mL polyacrylamide mother liquor (5wt%), add 45mL deionized water to dilute and form the homogeneous solution that concentration is 2%, drop 4.5mL graphene oxide mother liquor (10mg / mL) under vigorous stirring state, control the graphene oxide in the solution The alkene concentration was 0.6 mg / mL. Add 464.4mg resorcinol, 1.26mL formaldehyde (37wt%), 2.67g NiCl to the solution 2 ·6H 2 O and 300 μL of hydrochloric acid (3mol / L), and add 0.18 g of ascorbic acid as a reducing agent for graphene oxide. After the mixture solution was stirred evenly, it was transferred to a 100 mL polytetrafluoroethylene-lined autoclave, and subjected to a hydrothermal reaction at 130 °C for 15 h to obtain a reduced graphene oxide / cross-linked polyacrylamide / nickel chloride hydrogel. The gel was quickly frozen with liquid nitrogen, and dried in a freeze dryer for 24 hours (temperature -50°C, vacuum degree 8Pa) to obtain a reduced graphene oxide / cross-linked polyacrylamide / nickel chlori...

Embodiment 2

[0032] Get 30mL of polyacrylamide mother liquor (5wt%), add 45mL of deionized water to dilute and form a uniform solution with a concentration of 2%, add 6.0mL of graphene oxide mother liquor (10mg / mL) dropwise under vigorous stirring, and control the amount of graphite oxide in the solution. The alkene concentration was 0.8 mg / mL. Add 464.4mg resorcinol, 1.26mL formaldehyde (37wt%), 2.67g NiCl to the solution 2 ·6H 2 O and 300 μL of hydrochloric acid (3mol / L), and add 0.24 g of ascorbic acid as a reducing agent for graphene oxide. After the mixture solution was stirred evenly, it was transferred to a 100 mL polytetrafluoroethylene-lined autoclave, and subjected to a hydrothermal reaction at 130 °C for 15 h to obtain a reduced graphene oxide / cross-linked polyacrylamide / nickel chloride hydrogel. The gel was quickly frozen with liquid nitrogen, and dried in a freeze dryer for 24 hours (temperature -50°C, vacuum degree 8Pa) to obtain a reduced graphene oxide / cross-linked polyac...

Embodiment 3

[0034] Get 30mL of polyacrylamide mother liquor (5wt%), add 45mL of deionized water to dilute and form a uniform solution with a concentration of 2%, add 7.5mL of graphene oxide mother liquor (10mg / mL) dropwise under vigorous stirring, and control the amount of graphite oxide in the solution. The alkene concentration was 1.0 mg / mL. Add 464.4mg resorcinol, 1.26mL formaldehyde (37wt%), 2.67g NiCl to the solution 2 ·6H 2 O and 300 μL of hydrochloric acid (3mol / L), and add 0.30 g of ascorbic acid as a reducing agent for graphene oxide. After the mixture solution was stirred evenly, it was transferred to a 100 mL polytetrafluoroethylene-lined autoclave, and subjected to a hydrothermal reaction at 130 °C for 15 h to obtain a reduced graphene oxide / cross-linked polyacrylamide / nickel chloride hydrogel. The gel was quickly frozen with liquid nitrogen, and dried in a freeze dryer for 24 hours (temperature -50°C, vacuum degree 8Pa) to obtain a reduced graphene oxide / cross-linked polyac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com