Positive electrode plate and polymer electrolyte membrane combined piece and preparation method thereof

A technology of electrolyte membrane and positive pole piece, which is applied in the field of preparation of positive electrode material pole piece of solid-state battery, can solve the problems of insufficient solid-solid interface contact and large impedance, and achieves improved electrochemical performance, improved compatibility, and improved Coulombic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a combined sheet of a positive electrode sheet and a polymer electrolyte membrane, the method comprising the following steps:

[0032] Step (1), performing high-energy ball milling on the positive electrode active material and the ceramic-based solid electrolyte, so that the surface of the positive electrode active material is coated with the ceramic-based solid electrolyte, and set aside;

[0033] Preferably, the positive electrode active material is selected from lithium cobalt oxide (LCO), lithium iron phosphate (LFP), ternary positive electrode (NCM / NCA), lithium manganese oxide (LMO), spinel lithium nickel manganese oxide (LNMO ) and one or more of lithium-rich manganese bases; preferably lithium iron phosphate or lithium cobaltate;

[0034] Preferably, the ceramic-based solid electrolyte is one or more of lithium aluminum titanium phosphate (LATP), lithium aluminum germanium phosphate (LAGP), lithium lanthanum zirconiu...

Embodiment 1

[0078] After batching lithium iron phosphate (LFP) and lithium aluminum titanium phosphate (LATP) according to a mass ratio of 100:1, ball milling was carried out at a ball milling speed of 350 rpm for 6 hours to obtain lithium iron phosphate coated with LATP on the surface.

[0079] Weigh 5g of PEO with a molecular weight of 600,000 and disperse evenly in 25ml of DMF solvent under heating. After the solution is clarified, slowly add LiTFSI and stir until completely dissolved. Wherein, the molar ratio of monomer in PEO to lithium in LiTFSI is 16:1.

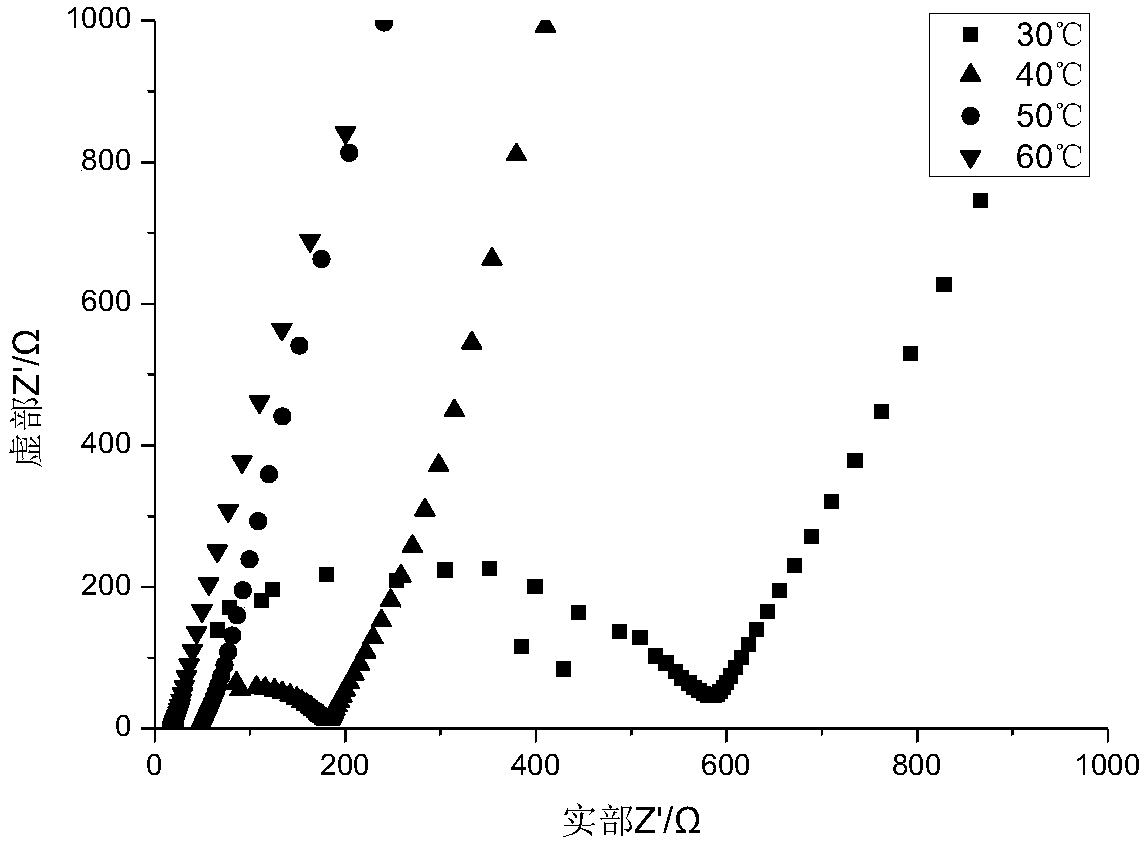

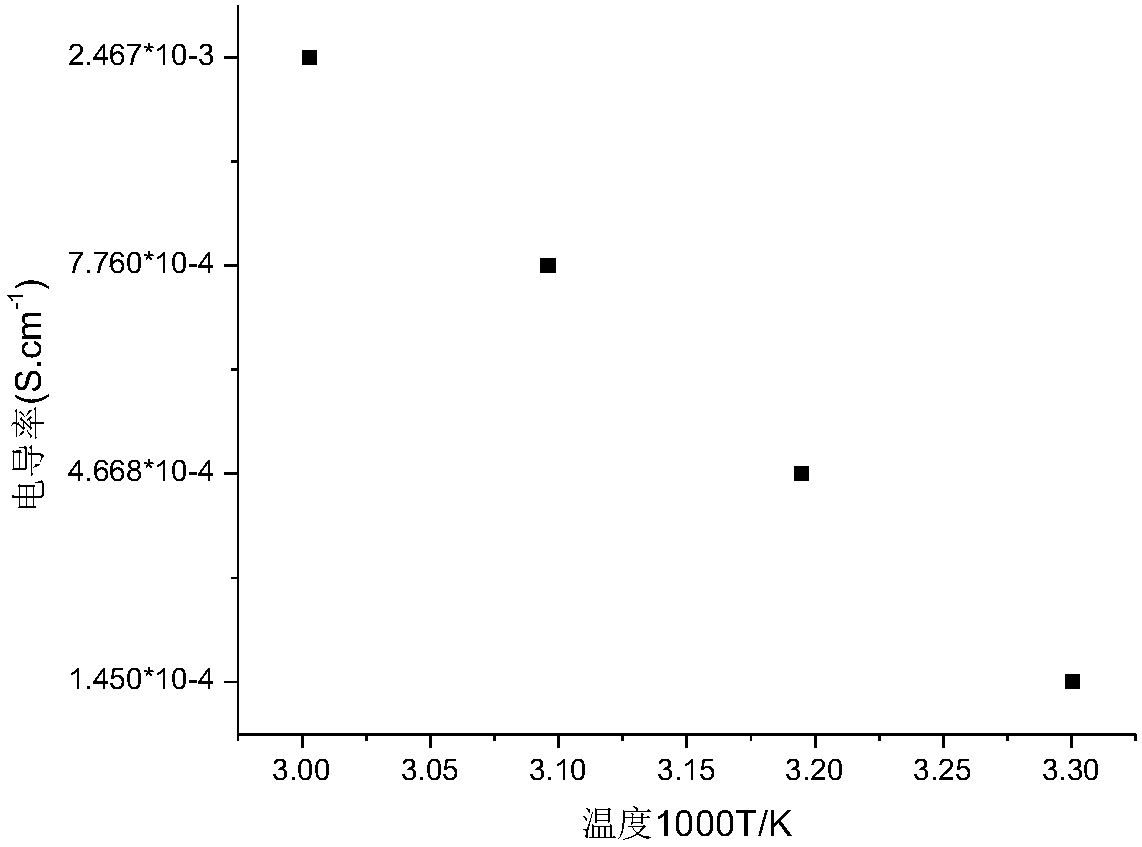

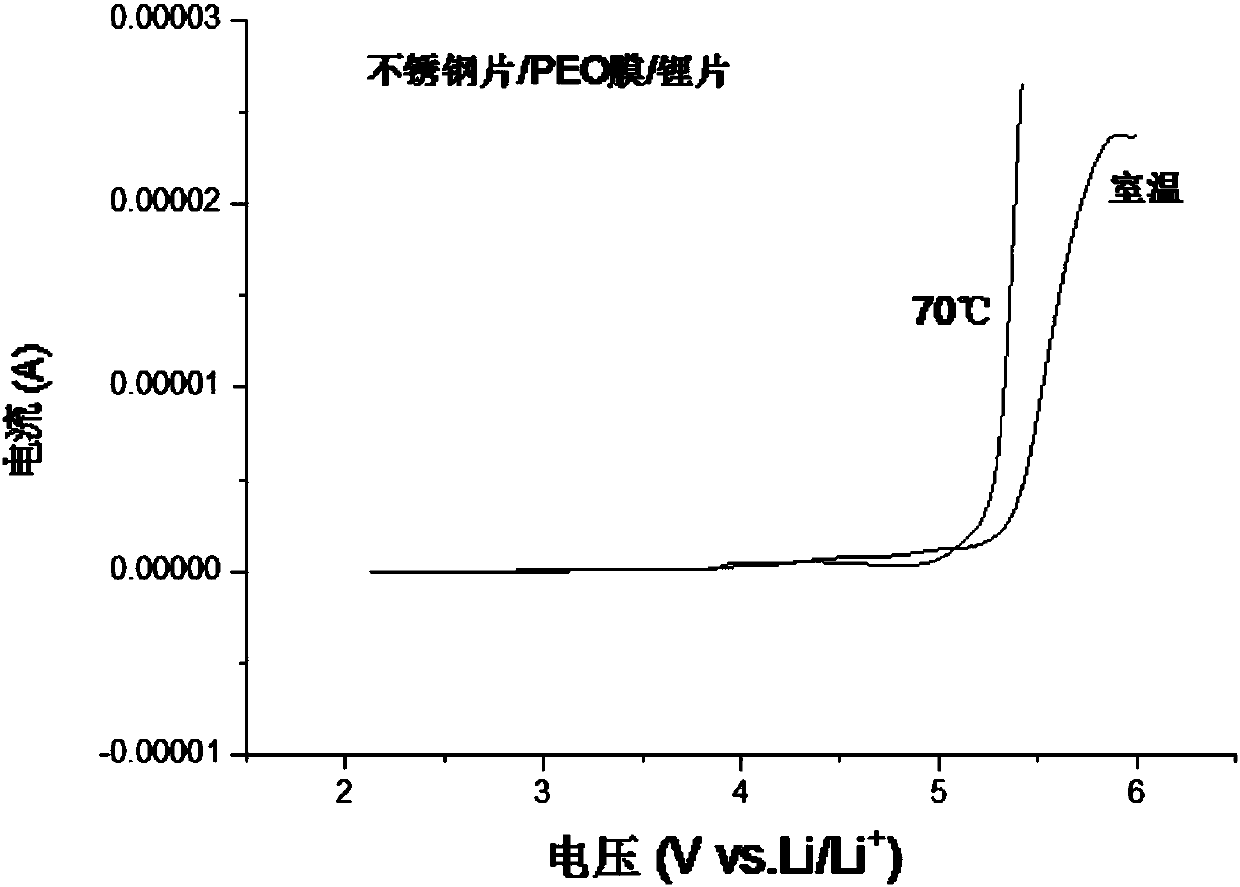

[0080] Take 20ml of the above solution, add 0.02g LATP into it, stir evenly, pour it directly on a polytetrafluoroethylene (PTFE) mold, and evaporate the solvent in a 50 degree oven to make a polymer electrolyte membrane.

[0081] At the same time, take 8g of lithium iron phosphate coated with LATP on the surface and 1g of carbon black, add them to the remaining DMF solution, continue to stir to form a uniform slurry, and coat it ...

Embodiment 2

[0086] Lithium cobalt oxide (LCO) and lithium aluminum titanium phosphate (LATP) were dosed according to a mass ratio of 100:1, and ball milled at a ball milling speed of 350 rpm for 6 hours to obtain lithium cobalt oxide coated with LATP on the surface.

[0087] Weigh 5g of PAN with a molecular weight of 150,000, and evenly disperse it in 25ml of DMF solvent under heating. After the solution is clarified, slowly add LiTFSI and stir until it is completely dissolved to obtain a PAN-LiTFSI polymer electrolyte. Among them, the molar ratio of monomer in PAN to lithium in LiTFSI is 12:1.

[0088] Take 20ml of the above solution, add 0.04g LATP to it, stir evenly, pour it directly on a polytetrafluoroethylene (PTFE) abrasive tool, and evaporate the solvent to dryness at 50°C to form a polymer electrolyte membrane.

[0089] At the same time, take 6g of lithium cobaltate coated with LATP on the surface and 3g of carbon black, add them to the remaining polymer electrolyte solution, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Charge specific capacity | aaaaa | aaaaa |

| Charge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com