Production process of alkoxy silane

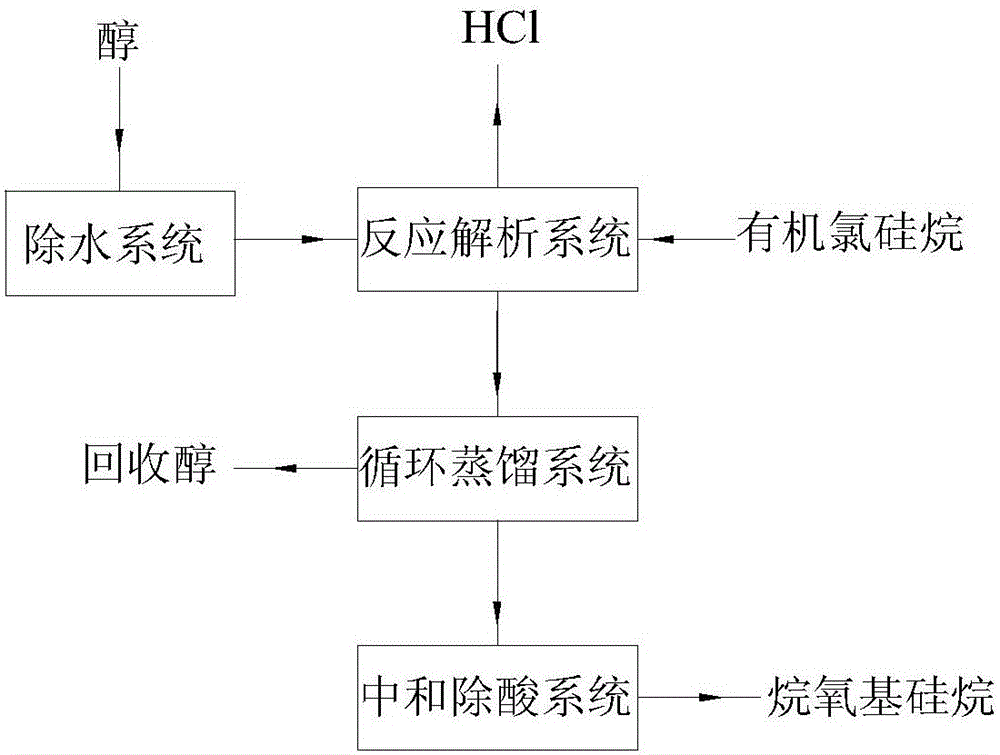

A technology of alkoxysilane and production process, which is applied in the production process field of preparing alkoxysilane by alcoholysis, and achieves the effect of reducing the existence of organic chlorine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The device used is a reaction analysis tower with a length of 4.8m and an inner diameter of 0.3m, which is filled with PTFE ring packing and regular corrugated packing. The height of the packing is about 2.3m. The gas phase outlet at the top of the tower is equipped with an outlet material condenser. After being adsorbed by molecular sieves, the water content in ethanol is 900ppm. The ethanol after water removal is added from the tower kettle, and the temperature of the kettle is controlled at 110-130°C. When a stable ethanol reflux appears at the top of the tower, methyltrichlorosilane is added from the top of the reaction analysis tower. After the ethanol began to reflux, the ethanol addition rate was reduced to 250kg / h. Adjust the adding rate of methyltrichlorosilane to about 250kg / h, so that the temperature at about 0.3m below the adding point of silane is 80-85°C, and make the temperature below the adding point of methyltrichlorosilane higher than the boiling poin...

Embodiment 2

[0036] The device used is a reaction analysis tower with a length of 4.8m and an inner diameter of 0.3m, which is filled with PTFE ring packing and regular corrugated packing. The height of the packing is about 2.3m. The gas phase outlet at the top of the tower is equipped with an outlet material condenser. After being adsorbed by molecular sieves, the water content in methanol is 730ppm. The methanol after water removal is added from the tower kettle, and the temperature of the kettle is controlled at 95-115°C. When a stable methanol reflux appears at the top of the tower, methyltrichlorosilane is added from the top of the reaction analysis tower. After methanol began to reflux, the ethanol addition rate was reduced to 200kg / h. Adjust the addition rate of methyltrichlorosilane to about 300kg / h, so that the temperature at about 0.3m below the addition point of silane is 65-70°C, and make the temperature below the addition point of methyltrichlorosilane higher than the boiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com