Automatic-cleaning type evaporative crystallization device

An automatic cleaning, evaporation and crystallization technology, applied in the direction of evaporation, separation, crystallization, evaporation, solution crystallization, etc., can solve the problems of insufficient efficiency, complex structure, and inability to meet the descaling requirements of crystallization evaporators, and achieve strong descaling and cleaning capabilities, Simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

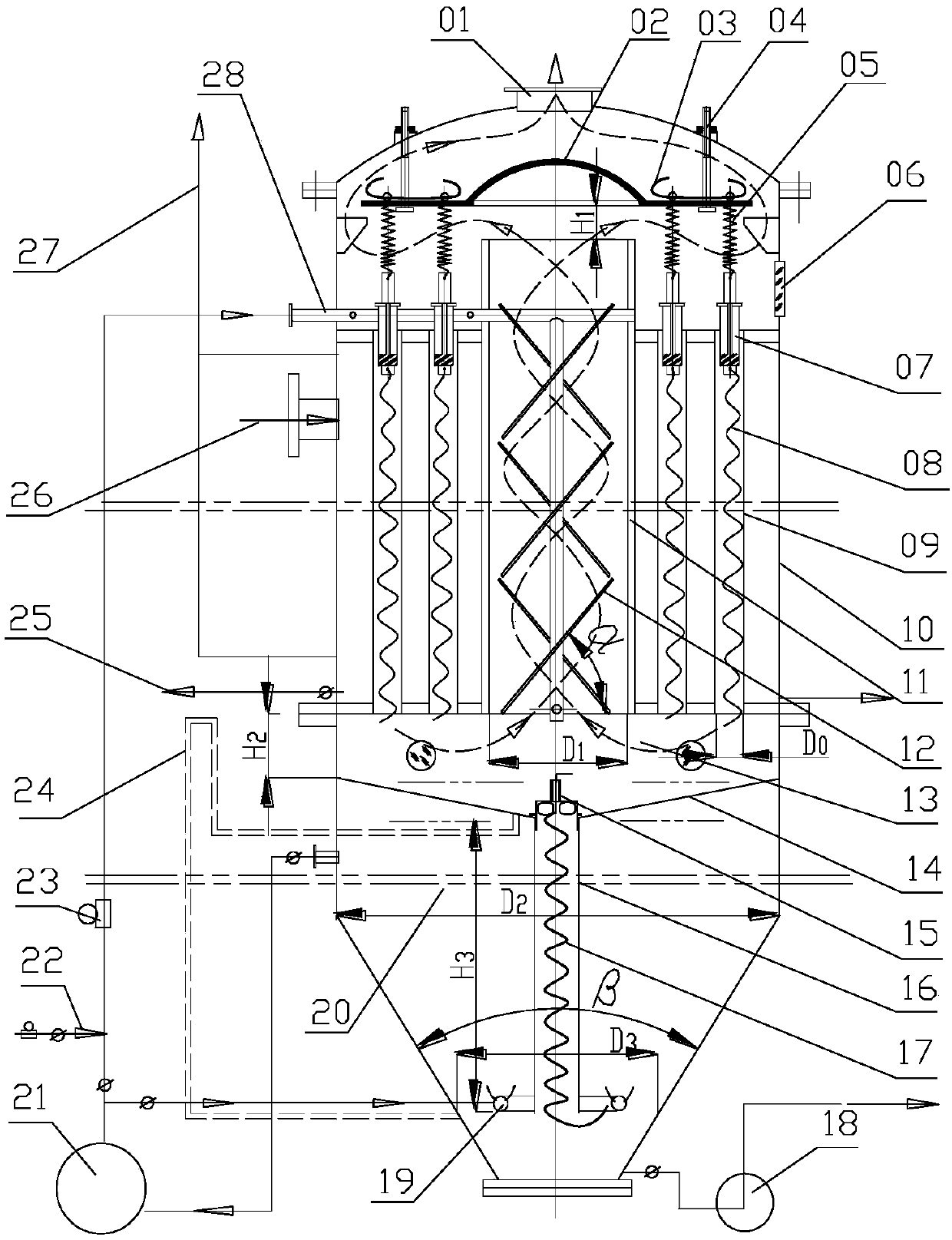

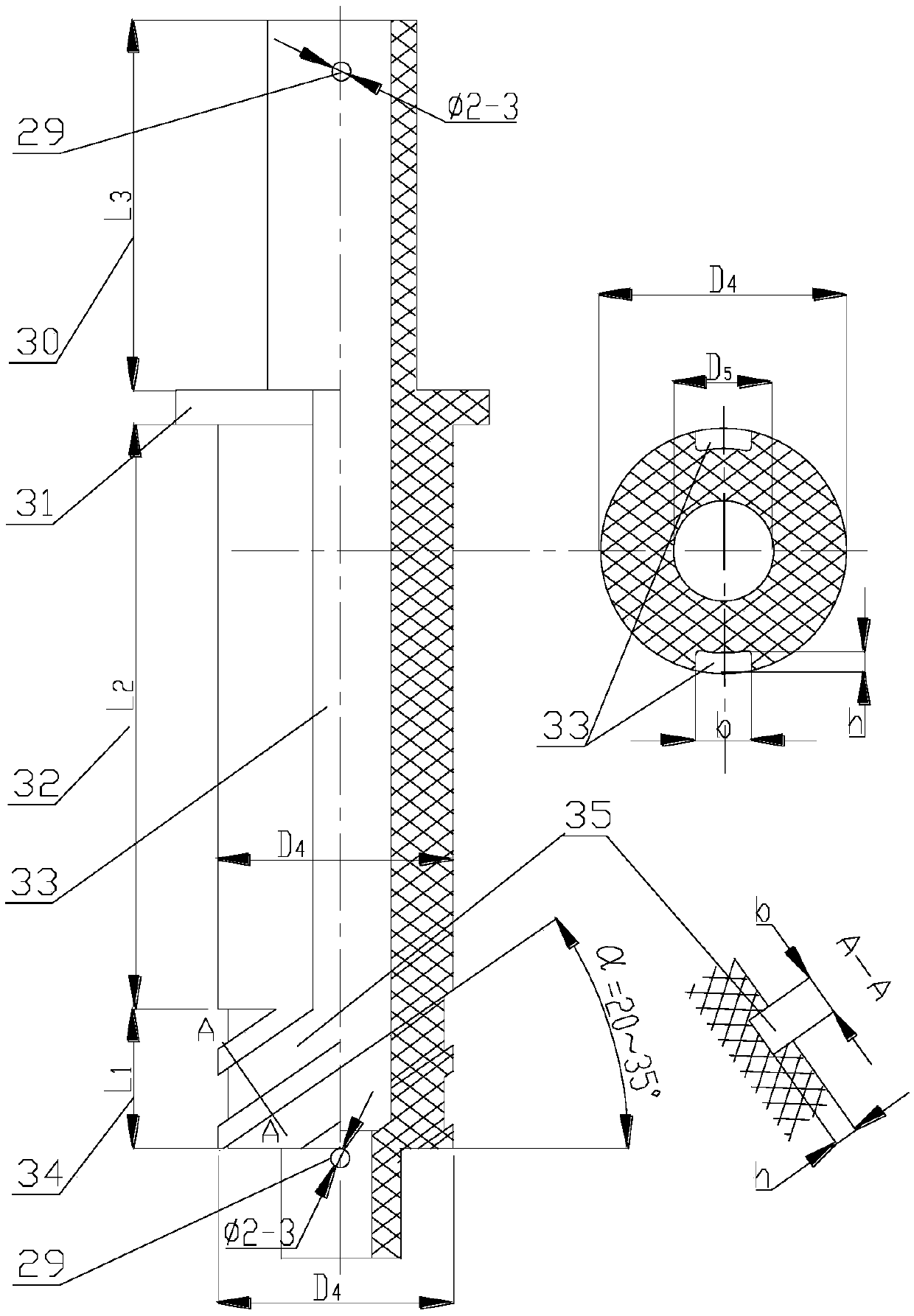

[0018] refer to figure 1 , figure 2 , a kind of self-cleaning type evaporation and crystallization device, has the top chamber 2 that self-cleaning mechanism 6 is installed, the falling film evaporator 26 of the top and demister 3, crystallization bottom tank 20 of the bottom, external circulation pump 21 system, make drop The five processes of membrane evaporation concentration, crystallization, dense deposition, coarse and fine classification, and defoaming are integrated.

[0019] The automatic cleaning mechanism 6 configur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com