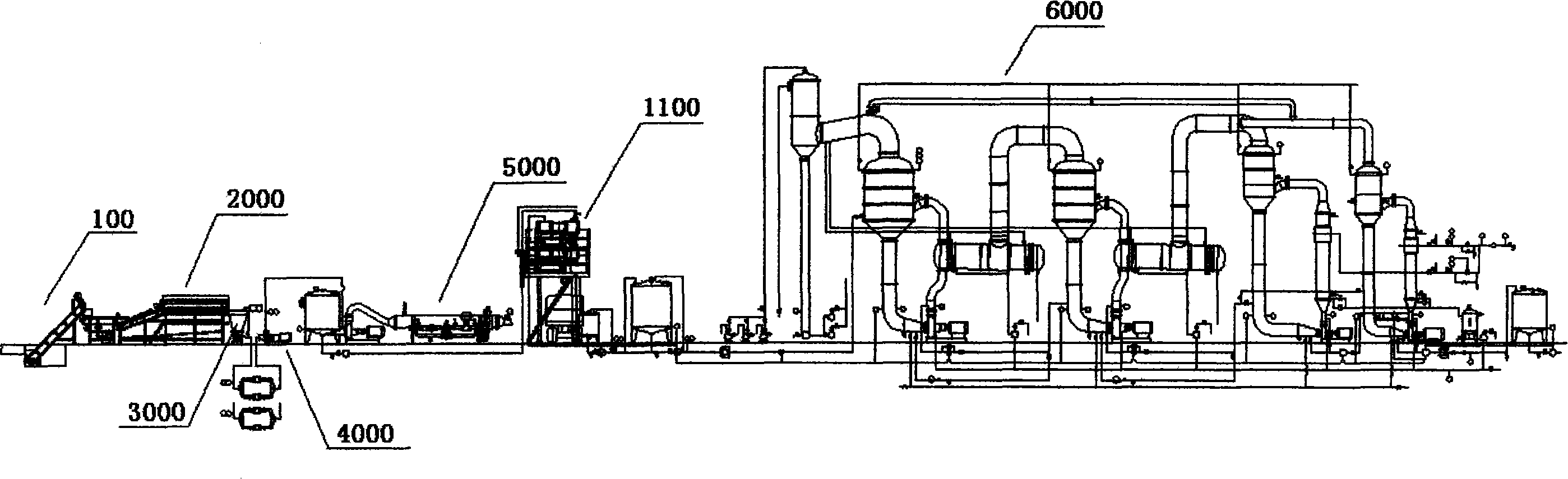

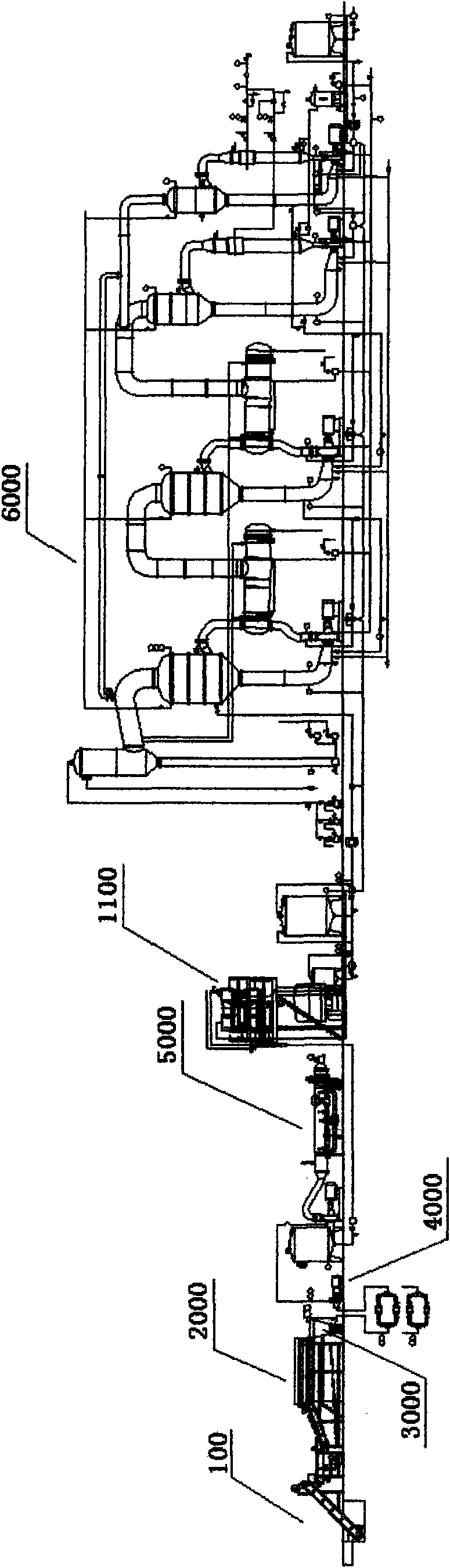

Complete production equipment for tomato sauce

A technology for producing equipment and tomato sauce, which is applied to the field of complete production equipment for producing tomato sauce, can solve the problems of small processing capacity, increase manpower and material resources, reduce production efficiency, etc., and achieve the effects of easy maintenance, large processing capacity and convenient operation.

Active Publication Date: 2010-11-24

上海神农节能环保科技股份有限公司

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the limitation of the storage period and the requirements for eating, people began to process fresh tomatoes into tomato paste in time after picking, freeze them for storage, and eat them for many years. They are necessary raw materials for meals and drinking, so the market prospect continues to be optimistic.

With the increase of my country's tomato production year by year, the tomato paste processing industry has also begun to flourish. According to statistics, my country currently imports hundreds of large-scale tomato paste processing lines, and the output is increasing year by year. However, the tomato paste processing industry is confused by the sauce produced The tomato sauce often cannot meet the world hygiene standard, which directly affects the competitiveness of my country's sauce in the international market. Attachments, or water-soluble pollutants, cannot achieve the ideal cleaning effect, and in the prior art, the two processes of cleaning and sorting are separated, which increases manpower and material resources, thereby greatly reducing production efficiency

However, the structure of the tomato sauce equipment in the prior art is relatively complicated, the processing capacity is small and cannot meet the market demand, and the operation and maintenance are very complicated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

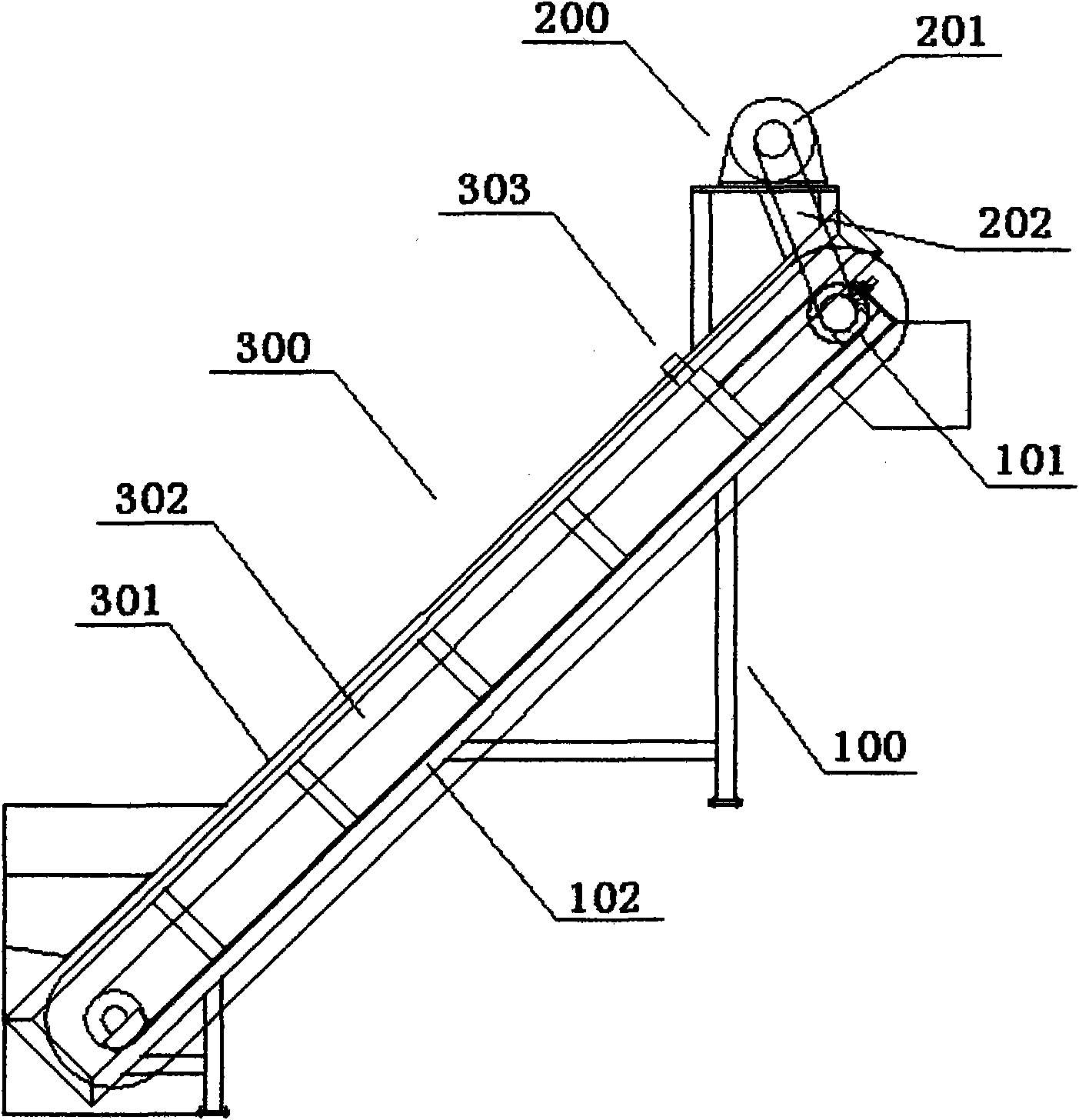

Login to View More Abstract

The invention discloses complete production equipment for tomato sauce, comprising a scraper lifting machine, a floatation machine, a crushing screw rod pump, a crushing pump, a pre-heater, a beating machine, a beating storage tank and a triple-effect four-section forced-circulation evaporator; one end of the floatation machine is connected with a scraper lifting machine and the other end is connected with the crushing screw rod pump; the crushing screw rod pump is connected with the crushing pump by a fixed-cutter weed extractor; the crushing pump is connected with the pre-heater for preheating the tomato sauce via the crushing storage tank; the discharge end of the pre-heater is connected with the beating machine of which one end is provided with the beating storage tank; the pipeline of the beating storage tank is connected with the triple-effect four-section forced-circulation evaporator; and the scraper lifting mechanism is aslant and fixedly installed on the frame and transmitted by a transmission device. The complete production equipment for tomato sauce of the invention has the advantages of advanced design, reasonable structure, high treatment capacity, high efficiency, convenient operation and easy maintenance.

Description

Complete set of tomato paste production equipment Technical field: The invention relates to the field of tomato paste production, in particular to a complete set of production equipment for producing tomato paste. Background technique: Ketchup is one of the main products with larger output, more exports and active development in my country's canned fruits and vegetables, and it is an international main commodity. In the world, the quality of tomato sauce is firstly evaluated by its color, followed by flavor and consistency. Therefore, the choice of good varieties is extremely important. The quality of raw materials directly affects the quality of finished products. The equipment used to produce tomato paste also has a direct impact on the quality and output of tomato paste. However, due to the limitation of the storage period and the requirements of eating, people began to process fresh tomatoes into tomato paste in time after picking, freeze them for storage, and eat th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23L1/24A23N15/06A23L27/60

Inventor 沈志平

Owner 上海神农节能环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com