Undulating flow reciprocating screw vibrating cleaning type natural circulating evaporator

A technology of natural circulation and fluctuating flow, applied in the field of automatic cleaning and heat transfer enhancement, it can solve the problems of insufficient cleaning ability of twisted belts and reduced technical difficulty, and achieve the effect of solving insufficient cleaning ability, reduced technical difficulty and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

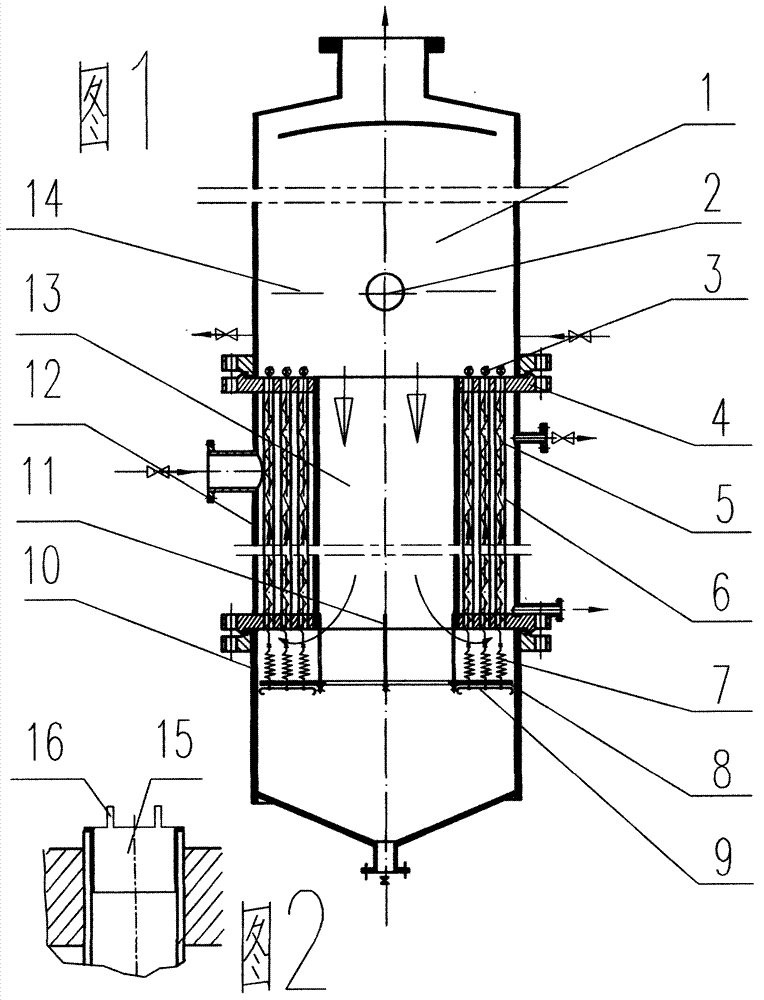

[0014] Attached below figure 1 , the present invention is described in further detail.

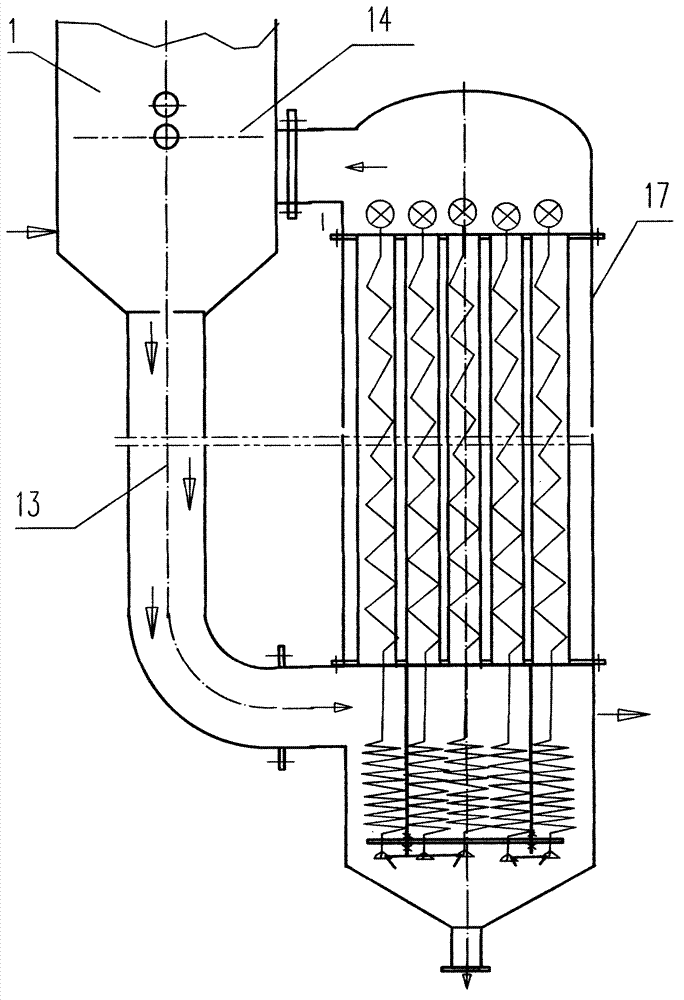

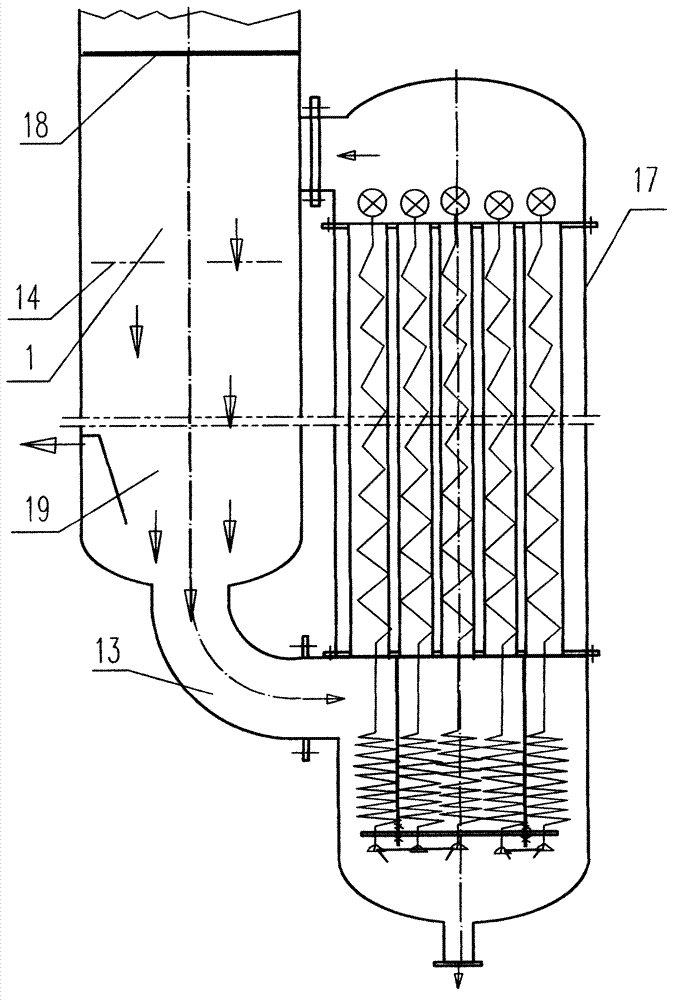

[0015] In the figure 1 evaporation chamber 2 mirror 3 strengthening ball 4 tube plate 5 undulating reciprocating spiral 6 heating tube 7 soft spring 8 assembly plate 9 grouping steel wire 10 bottom groove 11 fixed rod 12 heating chamber 13 natural circulation pipe 14 liquid surface 15 sheath 16 supporting ribs 17 outer heating chamber 18 tray 19 tower bottom

[0016] Fluctuating flow reciprocating spiral vibration cleaning type natural circulation evaporator, the main components are heating tube 6, fluctuating reciprocating spiral 5, soft spring 7, assembly plate 8, grouping steel wire 9, evaporation chamber 1, and natural circulation pipe 13.

[0017] The fluctuating reciprocating spiral 5 installed in the heating tube 6 is to utilize the fluctuating velocity of the unstable vapor-liquid two-phase flow caused by the steam bubbles in the evaporator heating tube 6, and the fluctuation of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic coefficient | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com