Heat coupling compression absorption type waste heat recovering type heat pump circulation system and method

A circulation system and absorption cycle technology, applied in the field of circulation system, can solve the problems of consumption, low efficiency, system consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

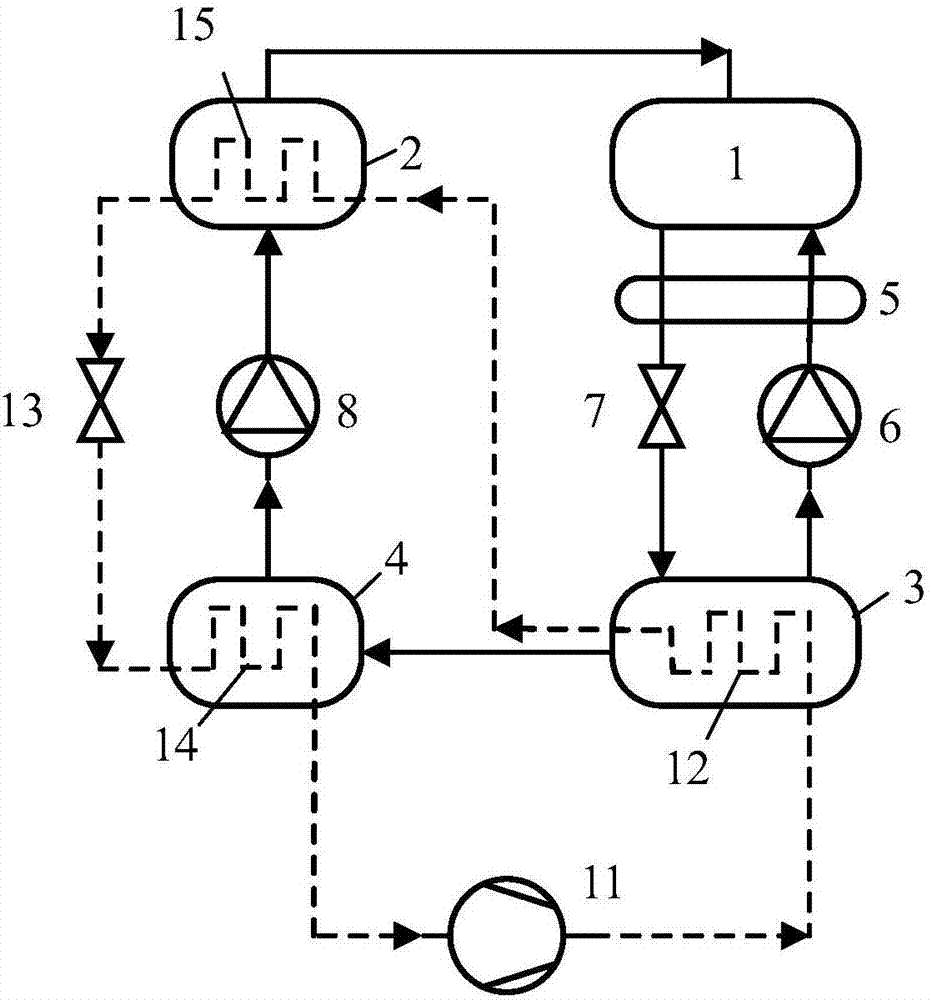

Embodiment 1

[0120] The circulatory system provided by the present invention is in the first working mode, that is, when the first working mode circulates, the component structure is as follows: figure 1 As shown, the main internal heat exchange of the cycle system operating in the first working mode is as follows: the first compression cycle condenser 12 exchanges heat with the generator 3, and the second compression cycle condenser 15 exchanges heat with the absorption cycle evaporator 2. Heat exchange, the absorption cycle condenser 4 and the compression cycle evaporator 14 perform heat exchange, the solution entering the absorber 1 from the solution pump 6 and the solution entering the first throttle valve 7 from the absorber are exchanged in the solution heat recovery device 5 hot. The external heat exchange of the circulation system is as follows: waste heat is input to the compression cycle evaporator 14, and the absorber 1 outputs heat to the outside.

[0121]When the circulation ...

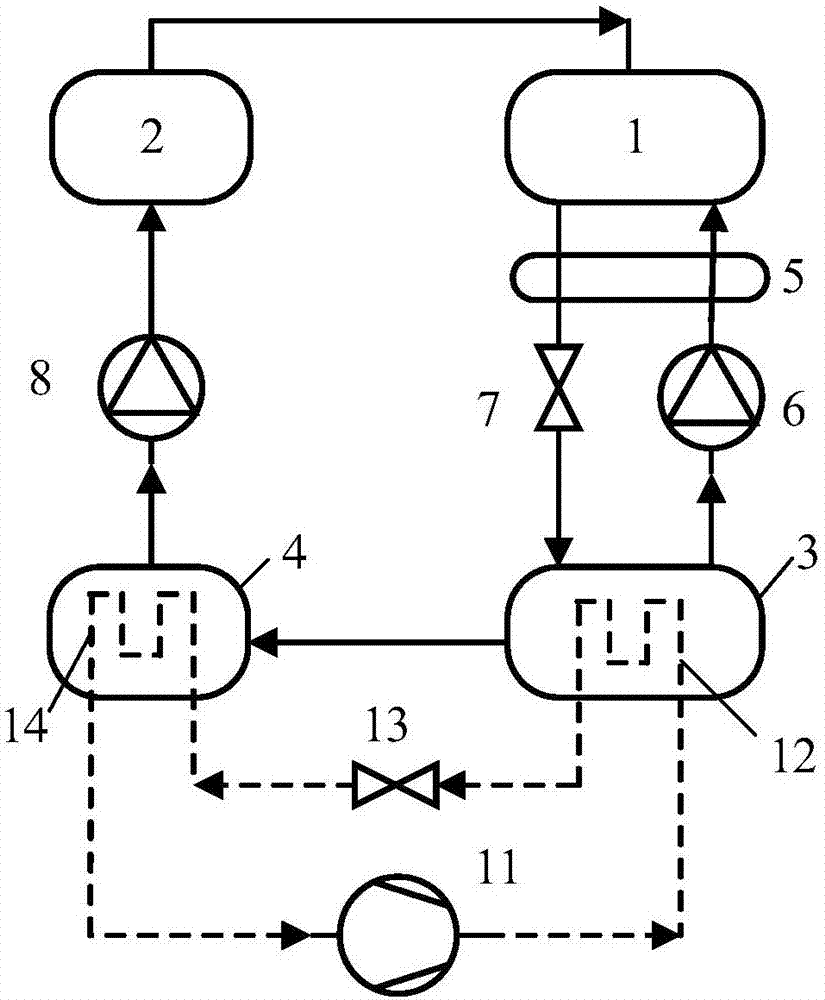

Embodiment 2

[0124] When the circulatory system circulates in the second working mode, that is, the second working mode, the structure of the components is as follows: figure 2 As shown, the main internal heat exchange of the circulation system operating in the second working mode is as follows: the first compression cycle condenser 12 exchanges heat with the generator 3, and the absorption cycle condenser 4 exchanges heat with the compression cycle evaporator 14. Heat, the solution entering the absorber 1 from the solution pump 6 and the solution entering the first throttling valve 7 from the absorber perform heat exchange in the solution heat recovery device 5 . The heat exchange between the circulation system and the outside world is as follows: heat from the environment is input to the compression cycle evaporator 14, waste heat is input to the absorption cycle evaporator 2, and the absorber 1 outputs heat to the outside.

[0125] When the system circulates in the second working mode,...

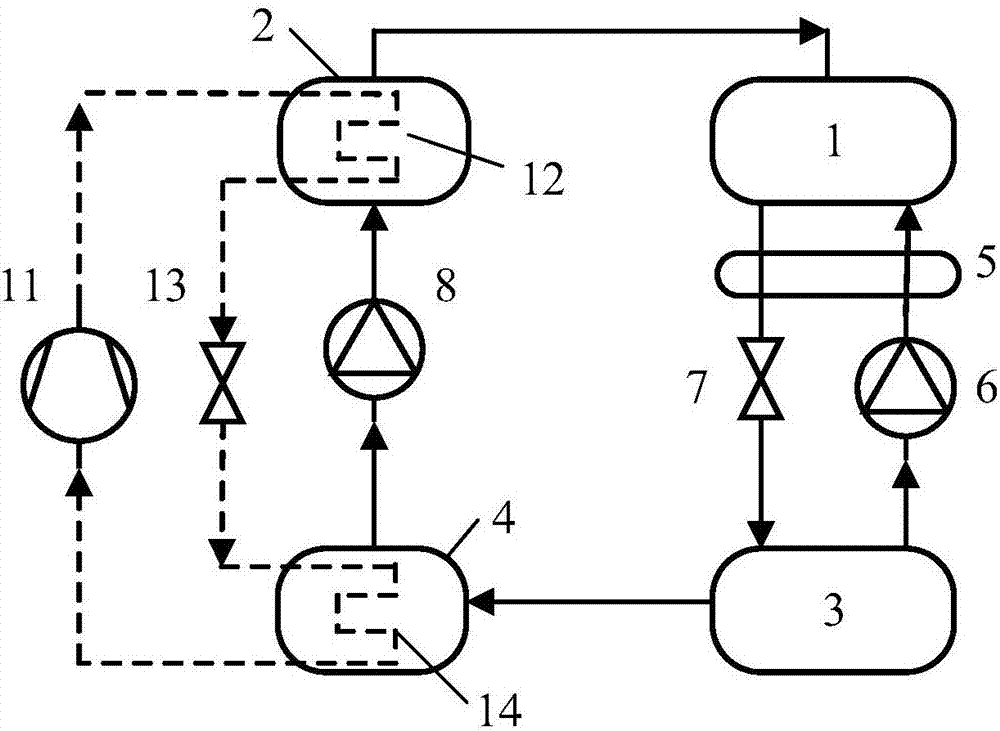

Embodiment 3

[0127] When the replacement system operates in the third working mode, that is, when the third working mode cycles, the structure of the components is as follows: image 3 As shown, the main internal heat exchange of the circulation system is as follows: the heat exchange between the compression cycle condenser 12 and the absorption cycle evaporator 2, the heat exchange between the absorption cycle condenser 4 and the compression cycle evaporator 14, and the solution pump 6 enters the absorber 1 solution and the solution entering the throttling valve 7 from the absorber perform heat exchange in the solution heat recovery device 5 . The heat exchange between the system and the outside is as follows: the ambient heat is input to the compression cycle evaporator 14, the waste heat is input to the generator 3, and the absorber 1 outputs heat to the outside.

[0128] When the system circulates in the third working mode, the internal working fluid flow of the compression heat pump s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com