Method for connecting and controlling pipelines of boron recovery system during overhaul

A recovery system and pipeline connection technology, applied in boron oxide compounds, auxiliary equipment of nuclear power plants, reduction of greenhouse gases, etc., can solve the problems of wasting processing time, increasing the workload of recirculating evaporators, increasing operating costs, etc., and reducing operating costs. , the effect of saving processing time and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

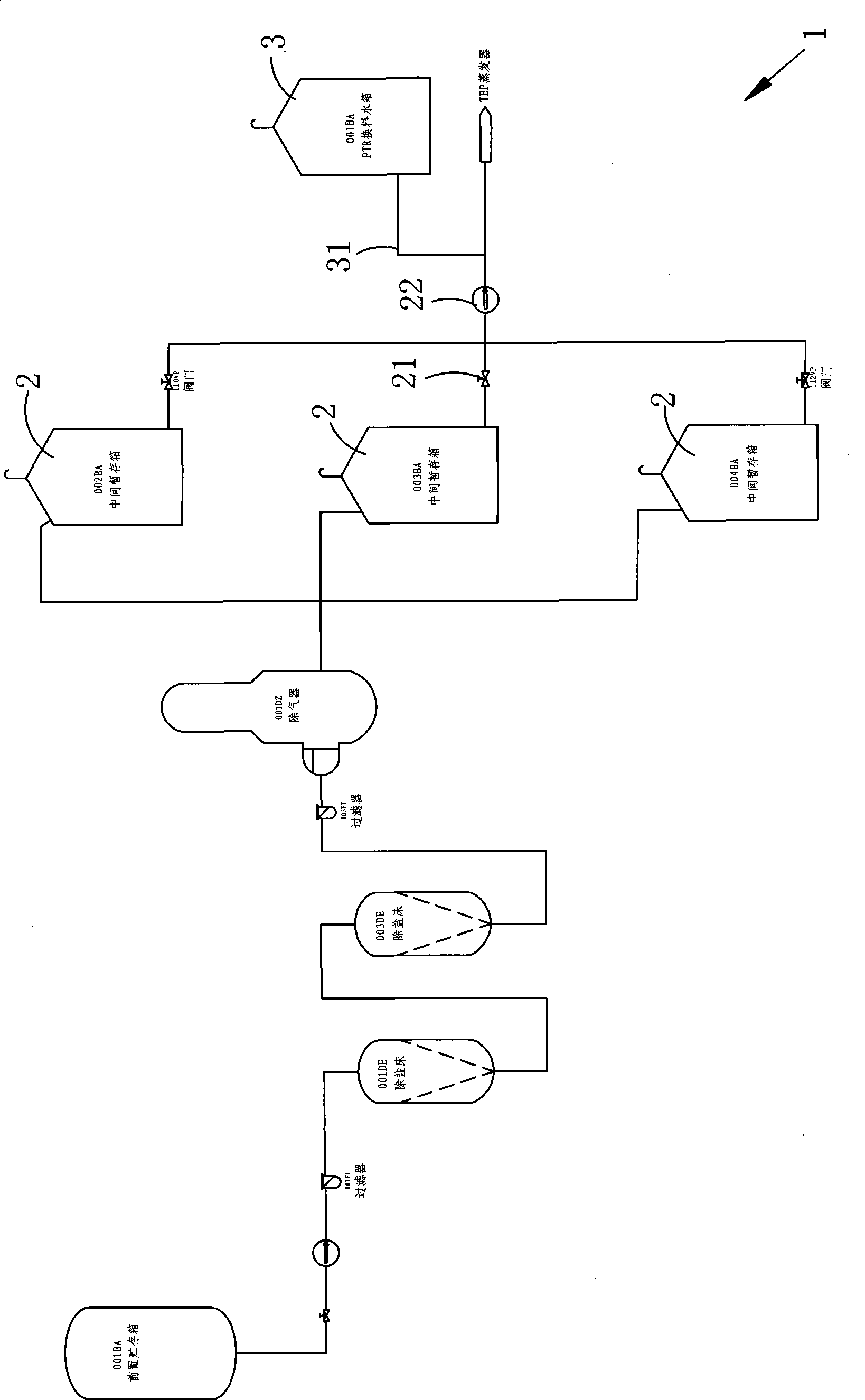

[0014] see figure 1 , the embodiment of the present invention provides a boron recovery system pipeline connection method during overhaul, the boron recovery system 1 includes an intermediate temporary storage 2, the intermediate temporary storage 2 has pre-treated reactor coolant, the intermediate temporary storage The downstream of 2 is provided with a refueling water tank 3, and the refueling water tank 3 is connected with the intermediate temporary storage 2.

[0015] Specifically, the reactor coolant in the above-mentioned intermediate storage 2 has been pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com