Double-effect evaporating and crystallizing production process of low-solubility, easy-crystallizing and thermosensitive material

A double-effect evaporation technology for heat-sensitive materials, applied in multi-effect evaporation, solution crystallization, evaporation, etc., can solve the problems of high discharge temperature of distilled water and condensed water, unsuitable long storage time, large discharge of distilled water, etc., to achieve production The effect of energy consumption reduction, environmental protection prevention and control cost reduction, and thermal energy utilization rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

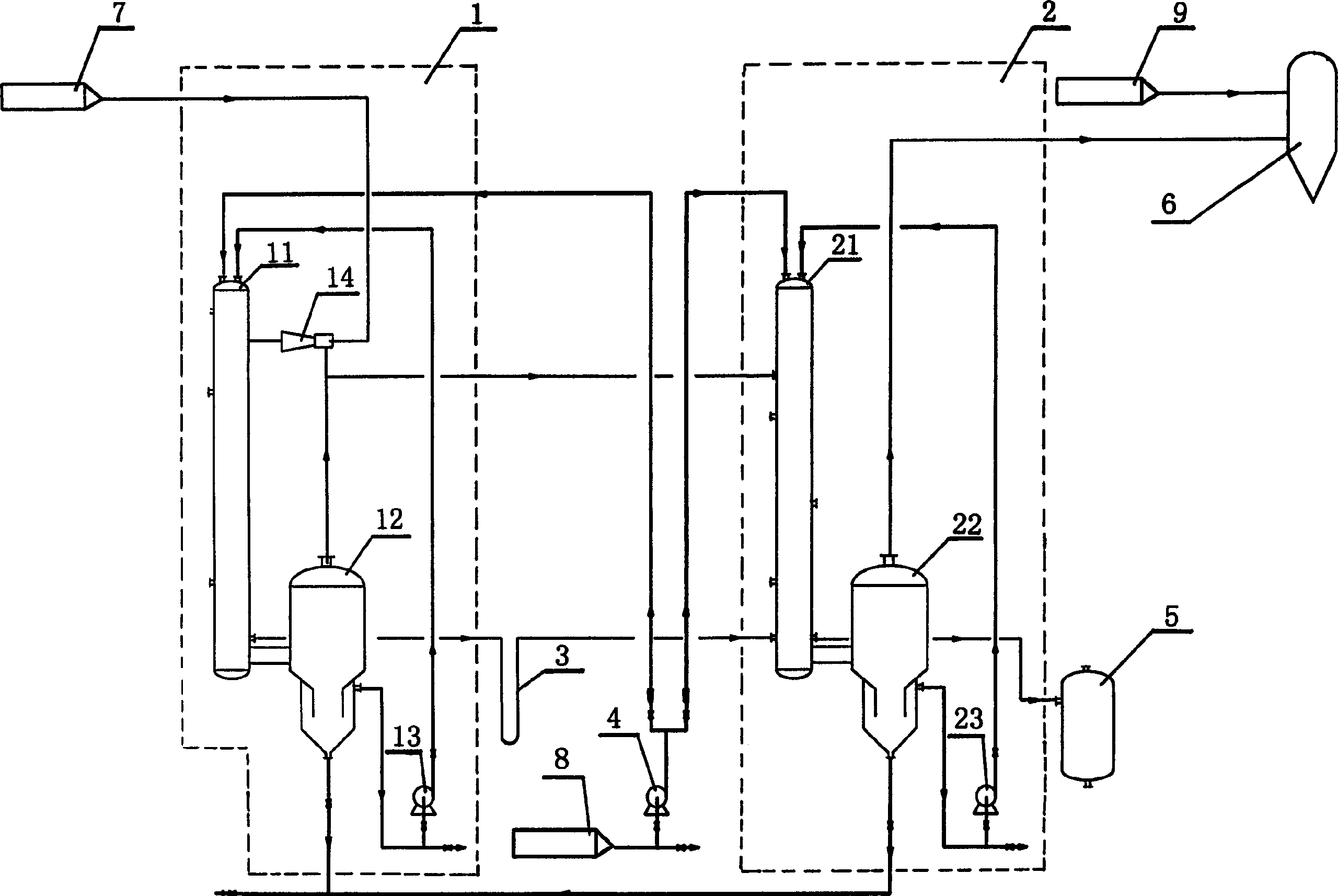

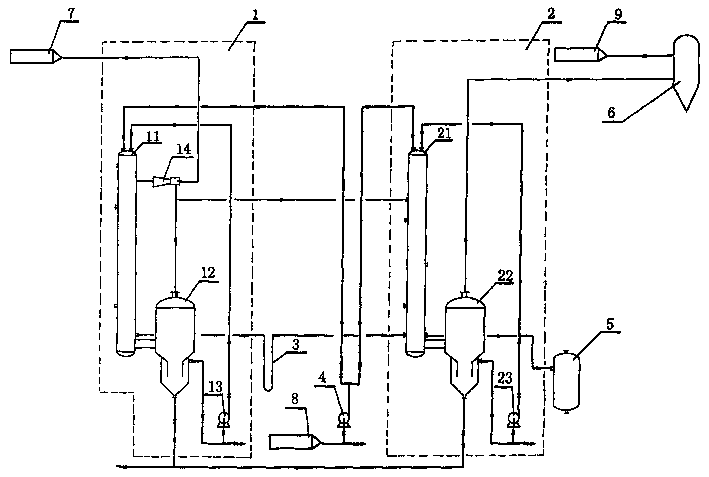

[0009] Example 1: Example 1 is an application of the improved low-solubility, easy-to-crystallization, heat-sensitive material double-effect evaporation crystallization production process provided by the present invention in the production of L-phenylglycine evaporation crystallization. Example 1 of the present invention provides a steam The improved L-phenylglycine double-effect evaporation and crystallization production process with a water volume of 5t / h adopts two sets of evaporation crystallization equipment, one set is composed of an external circulation evaporator 11, a vapor-liquid separator 12, a clear liquid circulation pump 13 and a heat pump 14, One-effect evaporation and crystallization equipment 1, a set of external circulation evaporator 21, vapor-liquid separator 22 and clear liquid circulation pump 23, two-effect evaporation and crystallization equipment 2, one-effect external circulation evaporator 11, two-effect external circulation evaporation Device 21 all ...

Embodiment 2

[0021] Example 2: Example 2 is another application of the improved low-solubility, easy-to-crystallize, heat-sensitive material double-effect evaporation crystallization production process in the production of L-phenylglycine evaporation crystallization. Example 2 of the present invention provides a The improved L-phenylglycine double-effect evaporation and crystallization production process with a distilled water volume of 10t / h uses two sets of evaporation and crystallization equipment, one of which is composed of an external circulation evaporator 11, a vapor-liquid separator 12, a clear liquid circulation pump 13 and a heat pump 14 , as a first-effect evaporation and crystallization equipment 1, a set is composed of an external circulation evaporator 21, a vapor-liquid separator 22 and a clear liquid circulation pump 23, as a second-effect evaporation and crystallization equipment 2, a first-effect external circulation evaporator 11, and a second-effect external circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com