Method and special device for collecting surplus heat of flushing cinder hot water of iron-smelting furnace

A hot water waste heat, iron-making blast furnace technology, applied in steam engine installations, mechanical equipment, machines/engines, etc., can solve the problems of heat loss, energy waste, environmental thermal pollution, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

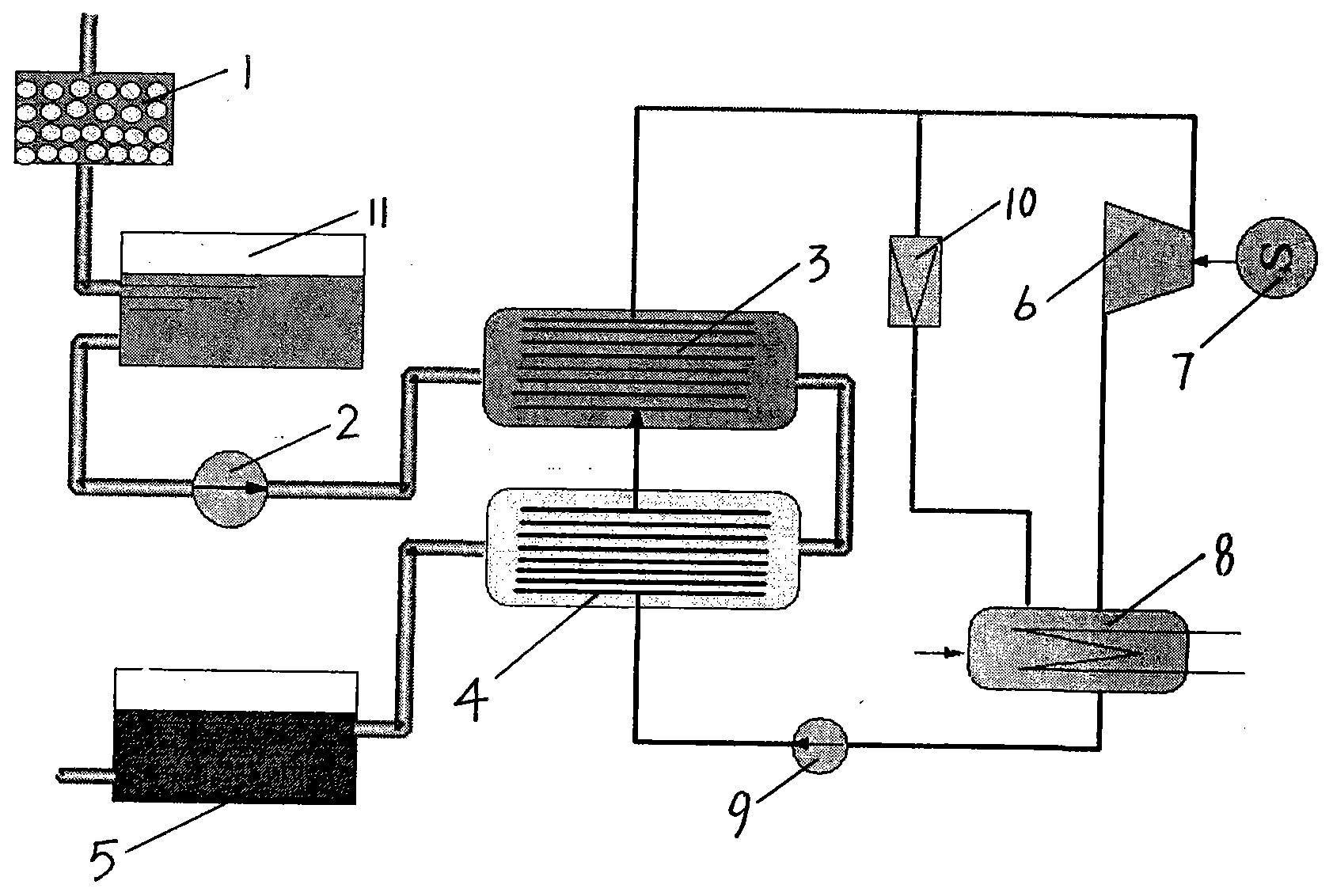

[0010] See figure 1 , the special equipment of the present invention includes a slag flushing water circulation loop and a medium circulation loop, a filter device 1, a circulating hot water pump 2, an evaporation heat exchanger 3, a preheating heat exchanger 4, a cold water pool 5, and a slag flushing equipment ( figure 1 The slag flushing equipment not expressed in ) are sequentially connected to form a slag flushing circulation loop; the medium flow pipe of the evaporating heat exchanger 3 is sequentially connected to the power machine 6, the condenser 8, the organic working medium pump 9, and the preheating heat exchanger 4 to form a circulation loop. 10 is a supplementary working medium pump, and 11 is a hot water pool.

[0011] The waste heat collection process of the present invention is described below in conjunction with the accompanying drawings: when the blast furnace slag water of the iron and steel plant is discharged, the temperature is about 85-90 ° C, and it en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com