Preparation method for nanometer titanium dioxide/coal ash composite material

A technology of nano-titanium dioxide and composite materials, which is applied in the field of preparation of nano-titanium dioxide/fly ash composite materials, can solve environmental pollution and other problems, and achieve great application potential and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

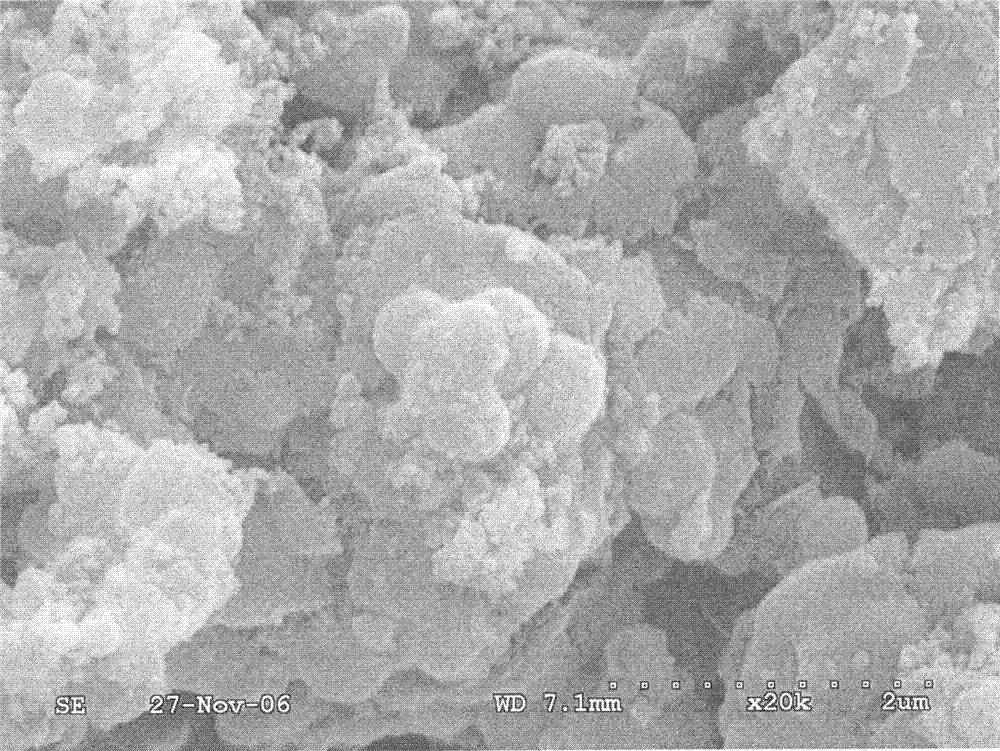

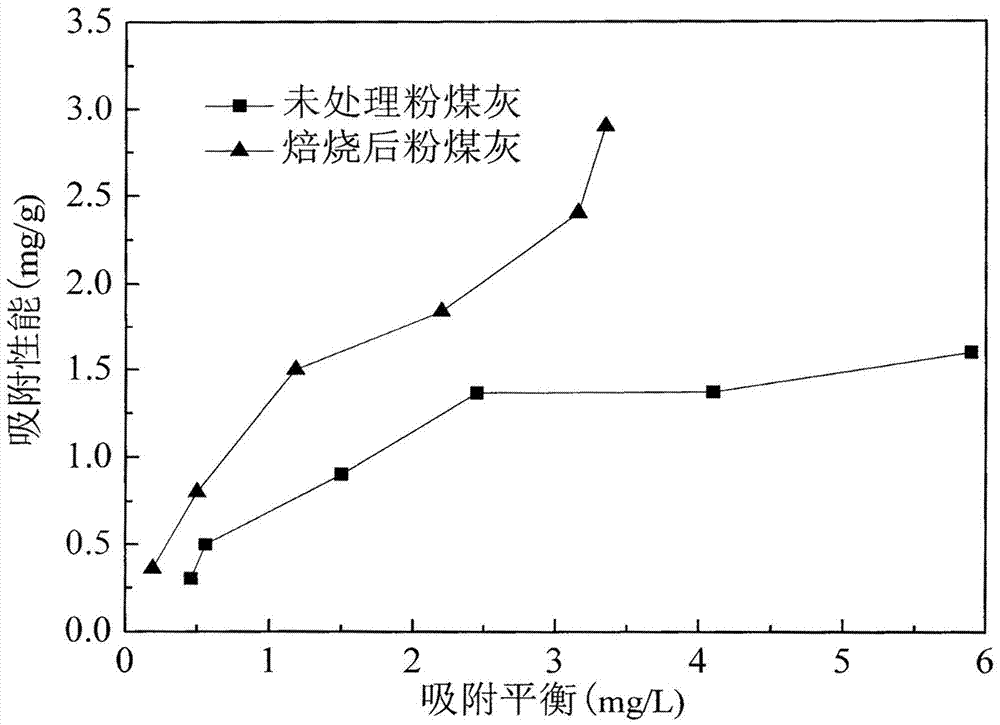

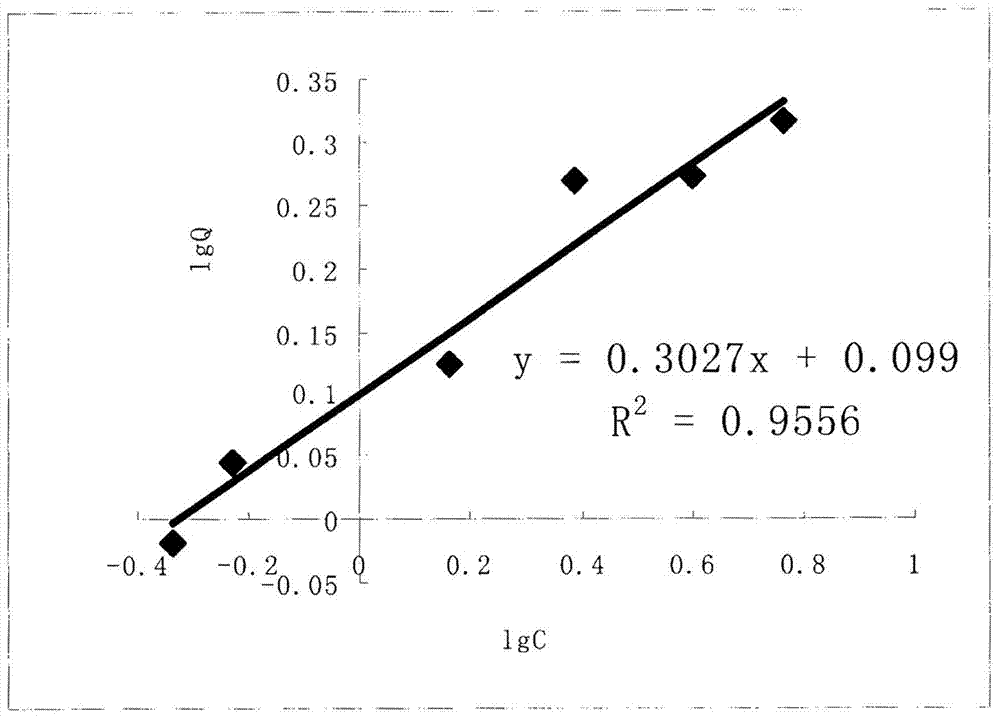

Image

Examples

Embodiment 1

[0029] (1) The raw material fly ash is heat-treated at a roasting temperature of 500°C. After cooling, take water and the roasted fly ash powder according to the liquid-solid ratio of 2.5L: 1Kg, stir and mix well, and then add concentrated sulfuric acid to adjust the pH value to 2.5, under the condition that the temperature of the water bath is kept at 100°C, fully stir the reaction for 4.5 hours, then add water according to the liquid-solid ratio of water to the above-mentioned roasted fly ash powder of 15L: 1Kg to dilute, react for 1 hour and filter the material, Dried to obtain refined fly ash.

[0030] (2) Under the condition of ice-water bath, take distilled water and refined fly ash according to the liquid-solid ratio of 3L: 1Kg, stir and add concentrated hydrochloric acid with 15% of the mass of refined fly ash at the same time, and then drop in the concentration of 28% of the mass of refined fly ash to be 2.9 mol / L TiCl4 solution; after the tablet was allowed to stand ...

Embodiment 2

[0034] (1) The raw material fly ash is heat-treated at a roasting temperature of 500°C. After cooling, take water and the roasted fly ash powder according to the liquid-solid ratio of 3L: 1.2Kg, stir and mix well, add concentrated sulfuric acid to adjust the pH When the value reaches 2, keep the water bath temperature at 100°C, fully stir the reaction for 4 hours, then add water to dilute according to the liquid-solid ratio of water to the above-mentioned roasted fly ash powder: 16L: 1.1Kg, and filter the material after reacting for 1 hour , drying to obtain refined fly ash.

[0035] (2) Under the condition of ice-water bath, take distilled water and refined fly ash according to the liquid-solid ratio of 3.2L:1.1Kg, stir and add concentrated hydrochloric acid with 15% of the mass of refined fly ash at the same time, and then drop in 30% of the mass of refined fly ash TiCl4 solution with a concentration of 3.0 mol / L; after standing the tablet for 13 minutes, add the aqueous sol...

Embodiment 3

[0039] (1) The raw material fly ash is heat-treated at a roasting temperature of 500°C. After cooling, take water and the roasted fly ash powder according to the liquid-solid ratio of 2L: 0.8Kg, stir and mix well, and then add concentrated sulfuric acid to adjust the pH When the value reaches 3, keep the water bath temperature at 100°C, fully stir the reaction for 4.5 hours, then add water according to the liquid-solid ratio of water to the above-mentioned roasted fly ash powder: 14L: 0.8Kg to dilute, and filter the material after reacting for 1 hour , drying to obtain refined fly ash.

[0040] (2) Under the condition of ice-water bath, take distilled water and refined fly ash according to the liquid-solid ratio of 2.5L: 0.8Kg, stir and add concentrated hydrochloric acid with 10% refined fly ash mass at the same time, and then drop in 25% refined fly ash mass TiCl4 solution with a concentration of 2.9 mol / L; after standing the tablet for 10 minutes, add the aqueous solution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com