Chemical modification method of coal pitch with unsaturated thermoplastic elastomer

A thermoplastic elastomer, chemical modification technology, applied in asphalt coatings, tar asphalt/petroleum asphalt/natural asphalt, anti-corrosion coatings, etc., to achieve the effect of improving universality, overcoming brittleness, and improving mutual compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The specific preparation steps of the chemical modification of coal tar pitch by unsaturated thermoplastic elastomer (SBS) are as follows:

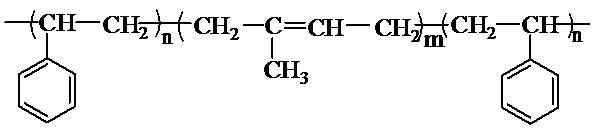

[0028] Mix 100 grams of coal tar pitch with a softening point of 65°C and 200 grams of organic solvent quinoline, stir at room temperature for 3 hours, stand still and filter to obtain a mother liquor, which is concentrated by evaporation at 150°C and vacuum-dried at 80°C to obtain refined coal tar pitch. 100 grams of refined coal tar pitch were heated to 80° C. under a nitrogen atmosphere and started to stir. Continue to heat up to 110°C, add 5 grams of SBS with a particle size of 100 mesh, SBS is a styrene-butadiene-styrene triblock copolymer copolymerized with styrene monomer and butadiene monomer, and the comonomer ratio is 40:60; heat up to 130°C at a heating rate of 2°C / min, so that the SBS particles basically disappear in the coal tar pitch matrix, then add 3 grams of boron trifluoride BF 3 , the reaction was stopped after ...

Embodiment 2

[0030]Add 100 grams of coal tar pitch with a softening point of 65°C to 200 grams of organic solvent tetrahydrofuran, stir at room temperature for 3 hours, stand still, and filter to obtain a mother liquor, which is concentrated by evaporation at 150°C and vacuum-dried at 80°C to obtain refined coal tar pitch. 100 grams of refined coal tar pitch were heated to 80° C. under a nitrogen atmosphere, and stirring was started. Continue to heat up to 110°C, add 15 grams of SBS with a particle size of 100 mesh, SBS is a styrene-butadiene-styrene triblock copolymer copolymerized with styrene monomer and butadiene monomer, and the comonomer ratio is 40:60; heat up to 150°C at a heating rate of 2°C / min. To make the SBS particles basically disappear in the coal tar pitch matrix, add 5 grams of boron trifluoride BF at this time 3 , the reaction was stopped after 5 hours of reaction to obtain SBS chemically modified coal tar pitch with a softening point of 98°C.

Embodiment 3

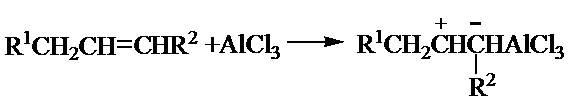

[0032] Add 100 grams of coal tar pitch with a softening point of 65°C to 200 grams of organic solvent toluene, stir at room temperature for 3 hours, let it stand, and filter to obtain a mother liquor. The mother liquor is concentrated by evaporation at 150°C and vacuum-dried at 80°C to obtain refined coal tar pitch. 100 grams of refined coal tar pitch were heated to 80° C. under a nitrogen atmosphere, and stirring was started. Continue to heat up to 100°C, add 2 grams of SBS with a particle size of 100 mesh, SBS is a styrene-butadiene-styrene triblock copolymer copolymerized with styrene monomer and butadiene monomer, and the comonomer ratio is 40:60; continue to heat up to about 140°C at 2°C / min. To make the SBS particles basically disappear in the coal tar pitch matrix, add 2 grams of catalyst aluminum chloride AlCl at this time 3 , after 2 hours of reaction, stop the reaction. The SBS modified coal tar pitch with a softening point of 78°C was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com