Method for preparing high-quality mesophase pitch by ternary co-carbonization

A technology of mesophase pitch and co-carbonization, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, chemically processing tar pitch/petroleum pitch/natural pitch, petroleum industry, etc. Energy consumption, expensive additives and other problems, to achieve the effect of less impurity ash content, increased reactivity, and improved optical appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

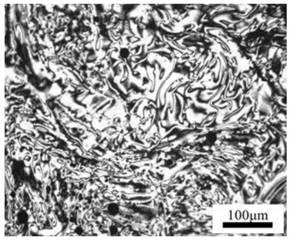

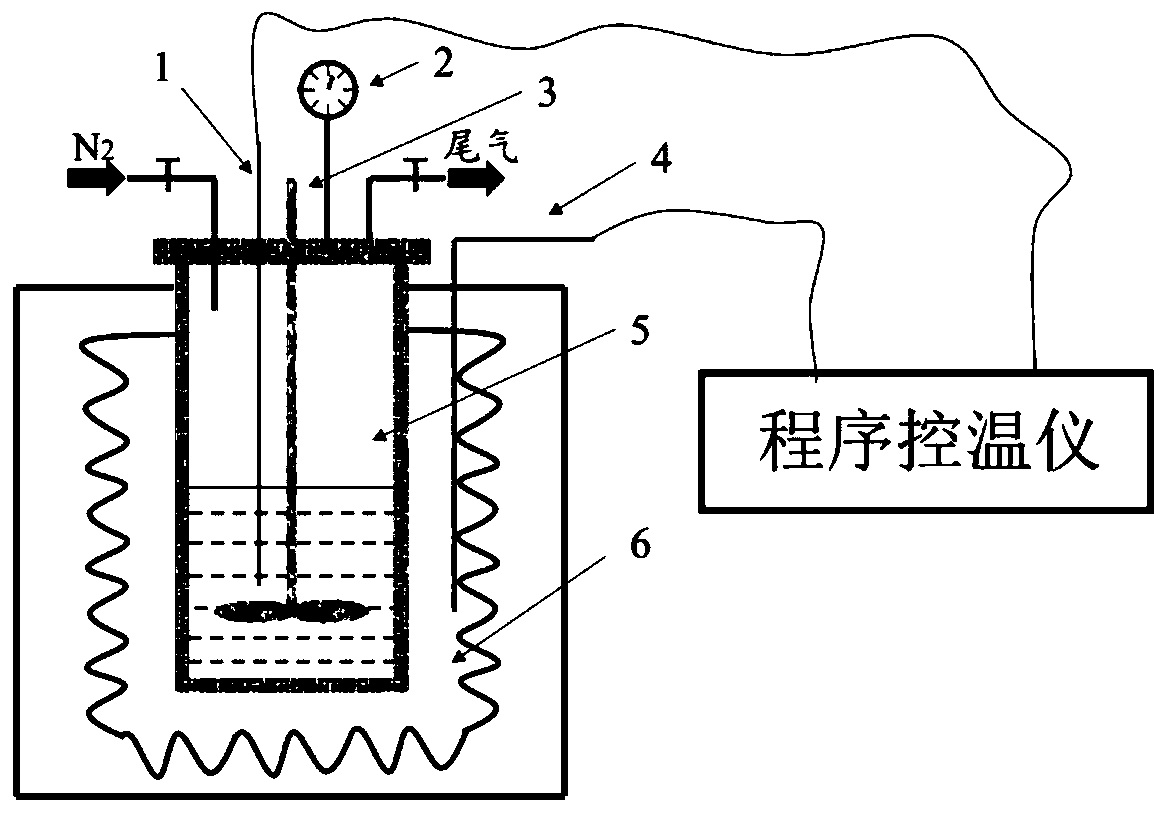

Embodiment 1

[0029] Put 400g of refined coal tar pitch raw material and 0.04g of graphene into a mixer for thorough mixing, then put the mixed powder and 10.59mL of tetrahydronaphthalene into a high-temperature and high-pressure reactor, blow nitrogen into it to purge and replace the air three times, and then seal the chamber. Describe the reactor, blow nitrogen into the reactor until the initial pressure is 0.2MPa, raise the temperature to 420°C at a rate of 2°C / min, start stirring when the temperature is greater than 120°C, the stirring rate is 350rmp, when the temperature rises to 420°C Keep warm for 10 hours. During the reaction, keep a closed constant pressure of 1.0MPa, and keep stirring at a constant speed. After the heat preservation is over, release the pressure, purging nitrogen for 30 minutes to remove light components, stop stirring, and cool to room temperature to obtain a wide-area streamlined mesophase pitch product with a softening point of 260°C, a mesophase content of up ...

Embodiment 2

[0031] Increase the quality of adding graphene from 0.04g to 0.12g, other conditions are the same as in Example 1, the softening point of the wide-area streamlined mesophase pitch product obtained is 256°C, the mesophase content is as high as 97%, and the quinoline insoluble content is 33wt %.

Embodiment 3

[0033] The quality of adding graphene is increased from 0.04g to 0.20g, and other conditions are the same as in Example 1. The softening point of the wide-area streamlined mesophase pitch product obtained is 252°C, the mesophase content is as high as 98%, and the quinoline insoluble content is 34wt %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com