Method for producing high quality ferronickel

A ferronickel, high-quality technology, applied in the field of ferronickel, can solve the problems of large amount of slag, high energy consumption, and low grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

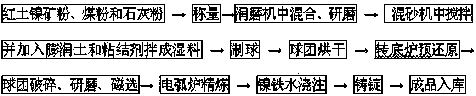

Image

Examples

Embodiment 1

[0017] The laterite nickel ore powder (2.25wt%Ni, particle size -200 mesh greater than 80%), clean coal powder (fixed carbon 90.2wt%, S0.13%wt, ash content 8%wt, volatile content 1.6%wt, particle size - The proportion of 200 mesh is greater than 70%) and lime powder (CaO67.2wt%, S0.006wt%, P0.003wt%, particle size -200 mesh is greater than 50%) according to the proportion of 85:10:5, weighing, and adding continuously Mix and grind in a moist mill, the raw materials are mixed in a moist mill for 60 minutes, the ratio of material to ball is 10:1.

[0018] Put the mixed raw materials into the sand mixer and then mix them mechanically. At the same time, add 2wt% bentonite, 2wt% syrup binder and 4wt% water to mix and wet the raw materials. The overall moisture content of the raw materials should be controlled at ≤9wt %; Afterwards, the wet material is continuously added to the double-roller briquetting machine and pressed into elliptical cold-consolidated pellets with a length of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com