Liquid-solid fluidizing bed coarse slime sorting system of three products and process of system

A technology of coarse coal slime and three products, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc. It can solve problems such as low, clean coal ash and gangue ash cannot guarantee the separation efficiency at the same time, and the narrow range of feed particle size, etc. problems, to achieve the effect of improving the recovery rate of clean coal, high recovery rate and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below in conjunction with the embodiment in the accompanying drawings:

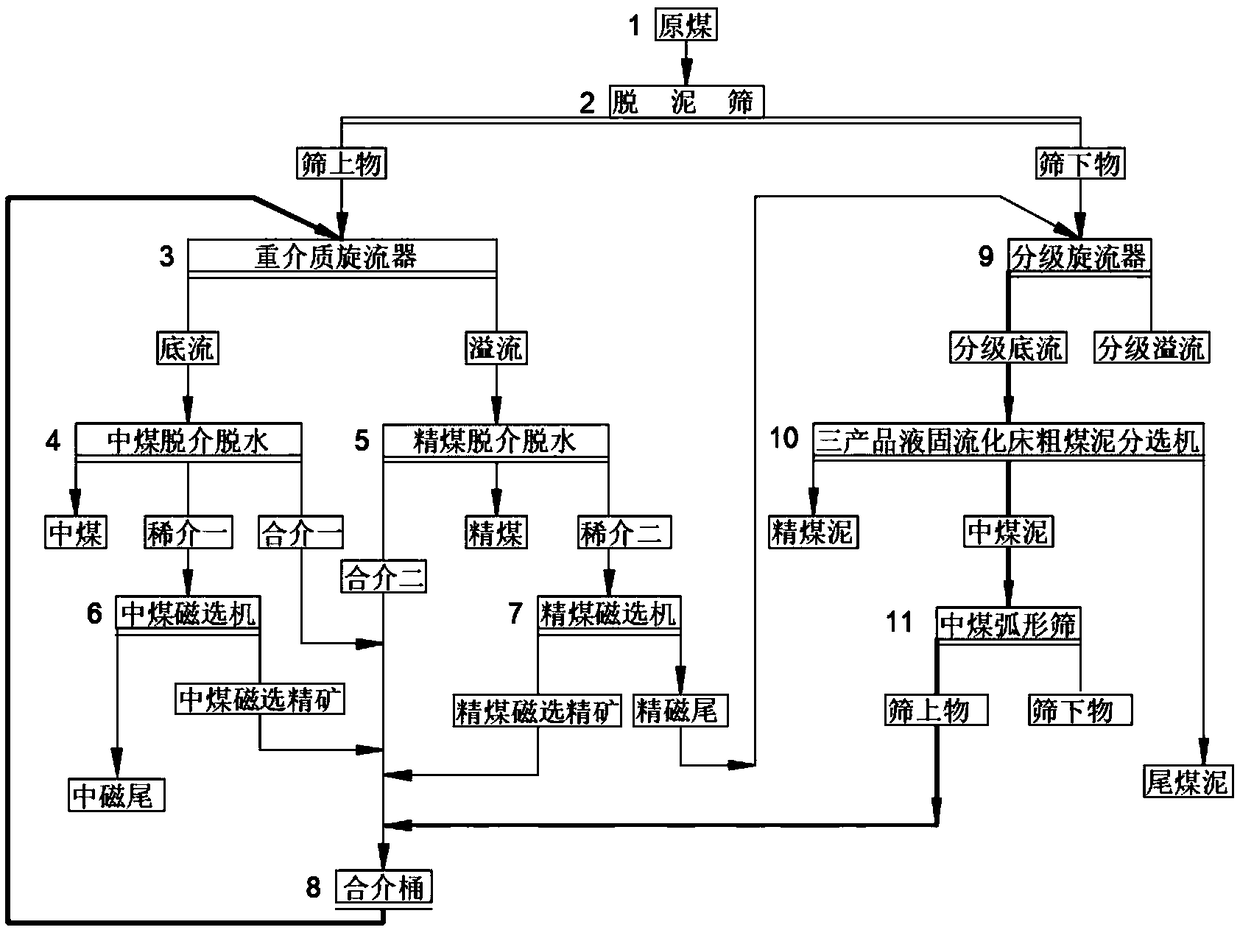

[0013] The three-product liquid-solid fluidized bed sorting coarse coal slime system of the present invention is mainly composed of a desliming screen 2, a dense medium cyclone 3, a medium coal magnetic separator 6, a clean coal magnetic separator 7, a combined barrel 8, The classification cyclone 9, the three-product liquid-solid fluidized bed coarse coal slime separator 10 and the medium coal arc screen 11 are composed, and the dense medium cyclone 3 is connected with the floating overflow port of the desliming screen 2, The grading flow applicator 9 is connected to the sinking material port of the desliming screen 2, and the medium coal magnetic separator 6 is connected to the outlet of the rare medium after the medium coal dehydration 4 in the bottom flow port of the dense medium cyclone 3, The clean coal magnetic separator 7 is connected with the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com