Activated carbon/aluminum oxide composite type catalyst carrier and preparation method and application of activated carbon/aluminum oxide composite type catalyst carrier

A technology of catalyst carrier and activated carbon, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems of difficult molding and low mechanical strength, and achieve the effect of large specific surface area and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

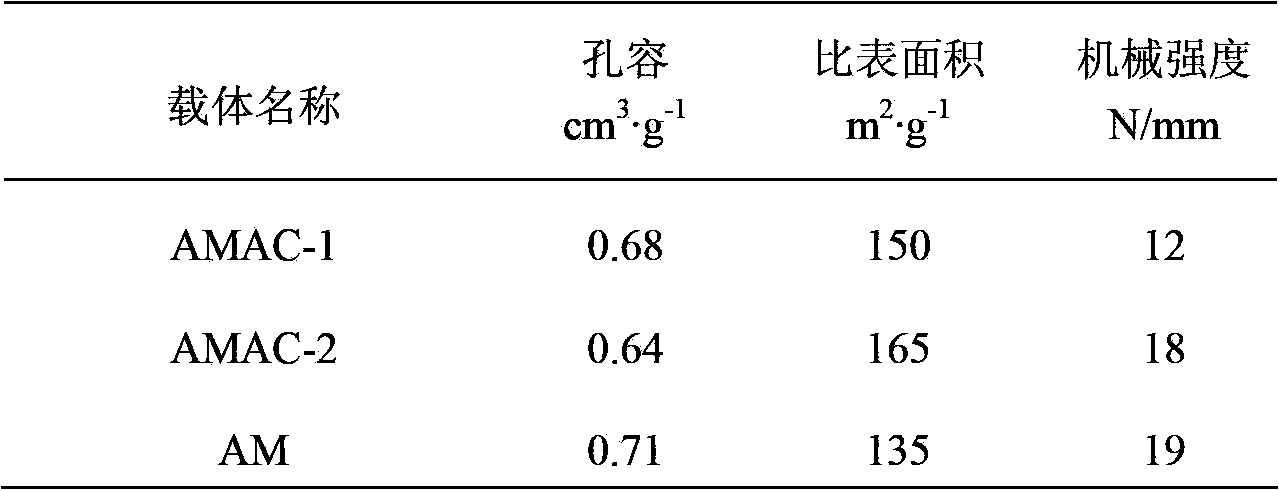

Embodiment 1

[0018] The composite ratio of alumina and activated carbon used in this example is 1:1, the specific preparation method:

[0019] (1) Activated carbon pickling and oxidation treatment: First, use 25% hydrochloric acid to circulate and wash for 5 hours in a boiling state, and the ratio of hydrochloric acid to activated carbon is 8:1; the activated carbon after pickling is treated with 35% nitric acid at room temperature 10h, the ratio of oxidant and activated carbon is 30:1.

[0020] (2) Mixing: Activated carbon and γ-Al 2 o 3 Mix according to the weight ratio of 1:1, add 1% acetic acid, 1% citric acid, and 2% scallop powder;

[0021] (3) Kneading: Knead activated carbon, alumina and additives into a cake under the kneader;

[0022] (4) Extrusion: Extrude the kneaded cake into a clover shape through an extruder;

[0023] (5) Roasting: Dry the extruded carrier at 120 °C, and then roast it at 500 °C for 2 h under nitrogen atmosphere to prepare γ-Al 2 o 3 / AC composite carri...

Embodiment 2

[0025] The composite ratio of alumina and activated carbon used in this example is 2:1, and the pickling and oxidation pretreatment of activated carbon are the same as step (1) in the example, and the specific preparation method is as follows:

[0026] (1) Mixing: Activated carbon and γ-Al 2 o 3 Mix according to the weight ratio of 1:1, add 1.5% of acetic acid, 2% of citric acid, and 3% of kale powder;

[0027] The rest of the steps are the same as in Example 1 to prepare a composite carrier, which is denoted as AMAC-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com