Fluorescent substance, method for production of the same, and light-emitting device using the same

A manufacturing method and a technology of a light-emitting device, which are applied in the field of phosphors and can solve problems such as reduction in brightness of phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach ”

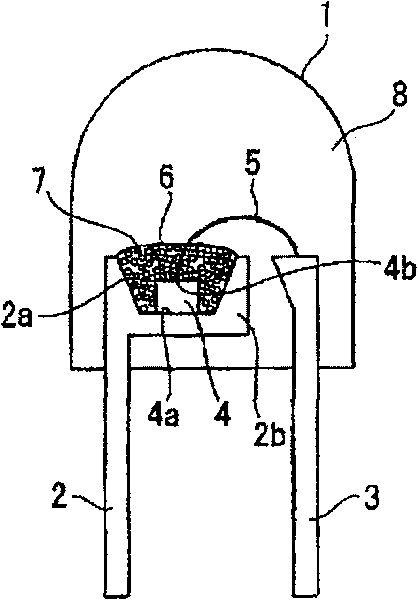

[0175] As the first embodiment of the lighting fixture of the present invention, for figure 1 The shown cannonball-shaped white light-emitting diode lamp (LED lighting fixture) 1 will be described.

[0176] A cannonball-shaped white light-emitting diode lamp 1 has a first lead 2 and a second lead 3. The first lead 2 has a recess 2a, and a blue light-emitting diode element 4 is mounted on the recess 2a. In the blue light-emitting diode element 4 , the lower electrode 4 a is electrically connected to the bottom surface of the concave portion 2 a with conductive paste, and the upper electrode 4 b is electrically connected to the bonding wire (gold thin wire) 5 through the second lead 3 .

[0177] The first resin 6 is a transparent resin in which phosphors 7 are dispersed, and covers the entirety of the blue light emitting diode element 4 . The end portion 2b of the first lead 2 including the concave portion 2a, the blue light emitting diode element 4, and the first resin 6 in wh...

no. 2 approach ”

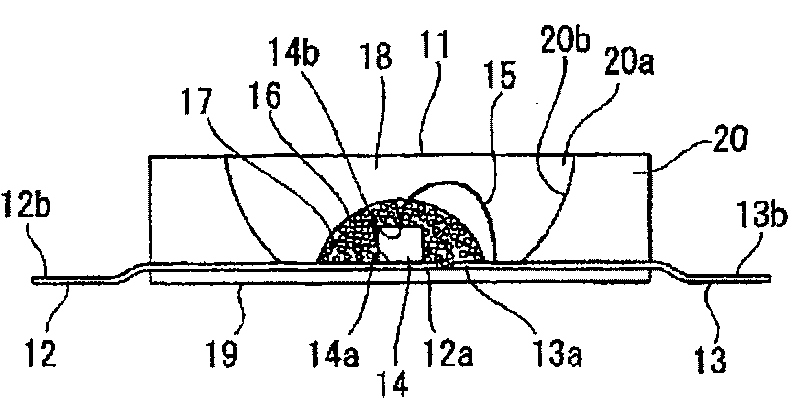

[0183] As the second embodiment of the lighting fixture of the present invention, for figure 2 The illustrated board mounting chip-type white light-emitting diode lamp (LED lighting fixture) 11 will be described.

[0184] The chip-type white light-emitting diode lamp 11 for substrate mounting has a third lead 12 and a fourth lead 13 fixed on a ceramic substrate 19 made of white alumina ceramics with high reflectance of visible light, and their ends 12a and 13a are located at In the substantially central portion of the substrate, the ends 12b and 13b on the opposite side are respectively exposed to the outside, and serve as electrodes to be soldered when mounted on the electric substrate.

[0185] The end 12a of the third lead 12 has a built-in and fixed blue light-emitting diode element 14 so as to be located in the center of the substrate. The lower electrode 14 a of the blue light emitting diode element 14 is electrically connected to the third lead 12 by conductive paste,...

Embodiment 1~10

[0208] First, Examples 1 to 10 of the phosphor of the present invention will be described.

[0209] As raw material powders, silicon nitride powder, aluminum nitride powder, strontium nitride powder, and europium nitride powder having an average particle diameter of 0.5 μm, an oxygen content of 0.93% by weight, and an α-type content of 92% were used.

[0210] Coordination (mass ratio, hereinafter also in other examples) represented in Table 2 weighs europium nitride powder, strontium nitride powder, aluminum nitride powder, silicon nitride powder, so that in the general formula Sr x M(1) y M(2) z Si 12-(m+n) Al (m+n) o n N 16-n The values of x, y, z, m, and n shown in Table 1 were used, and mixed for 30 minutes with an agate sucker and a mortar. In addition, M(1) is Eu.

[0211] Table 1

[0212]

x

y

z

m

n

Example 1

0.110

0.015

0.000

0.250

0.000

Example 2

0.235

0.015

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com