Composite cathode active material, cathode and lithium battery each including the same, and method of preparing composite cathode active material

A technology of active material and composite cathode, applied in battery electrodes, lithium storage batteries, active material electrodes, etc., can solve the problems of inability to provide thermal stability, deterioration of life characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0168] In the preparation of the composite positive electrode active material, the preparation of the lithium nickel transition metal oxide having a layered crystal structure comprises: mixing a precursor of the lithium nickel transition metal oxide with a metal precursor to prepare a mixture; and in an oxidative atmosphere The mixture is heat-treated at a temperature of 400° C. to 1000° C. to prepare a lithium nickel transition metal oxide.

[0169] The preparation of the mixture is carried out, for example, by a dry method without using a solvent. The mixture is, for example, a dry powder mixture of lithium nickel transition metal oxide precursor powder and metal precursor powder. In an embodiment, the preparation of the mixture is performed by, for example, a wet method involving a solvent. The mixture includes a solvent capable of dissolving the precursor of the lithium nickel transition metal oxide and the metal precursor, and the type of the solvent is not particularly ...

Embodiment 1

[0177] Embodiment 1: Preparation of composite positive electrode active material

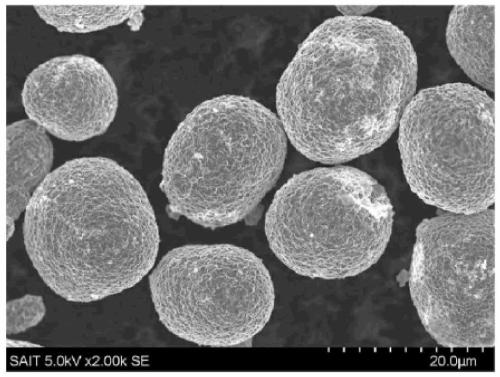

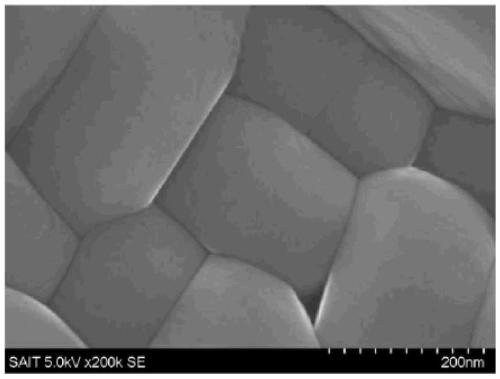

[0178] Zirconia (ZrO 2 ), alumina (Al 2 o 3 ), Ni 0.88 co 0.08 mn 0.04 (OH) 2 (Reshine NewMaterialCo., Ltd., China) and LiOH·H as a lithium precursor 2 O mixed to obtain the first mixture. Stoichiometric adjustment of zirconia (ZrO 2 ), alumina (Al 2 o 3 ), Ni 0.88 co 0.08 mn 0.04 (OH) 2 and LiOH H as a lithium precursor 2 The amount of O to obtain Li 1.09375 (Ni 0.88 co 0.08 mn 0.04 )Al 0.00125 Zr 0.0025 o 2 . Added Ni 0.88 co 0.08 mn 0.04 (OH) 2 The powder includes secondary particles which are aggregates of needle-shaped primary particles.

[0179] The first mixture was put into a furnace and subjected to a first heat treatment at 760° C. for 12 hours while flowing oxygen gas therein.

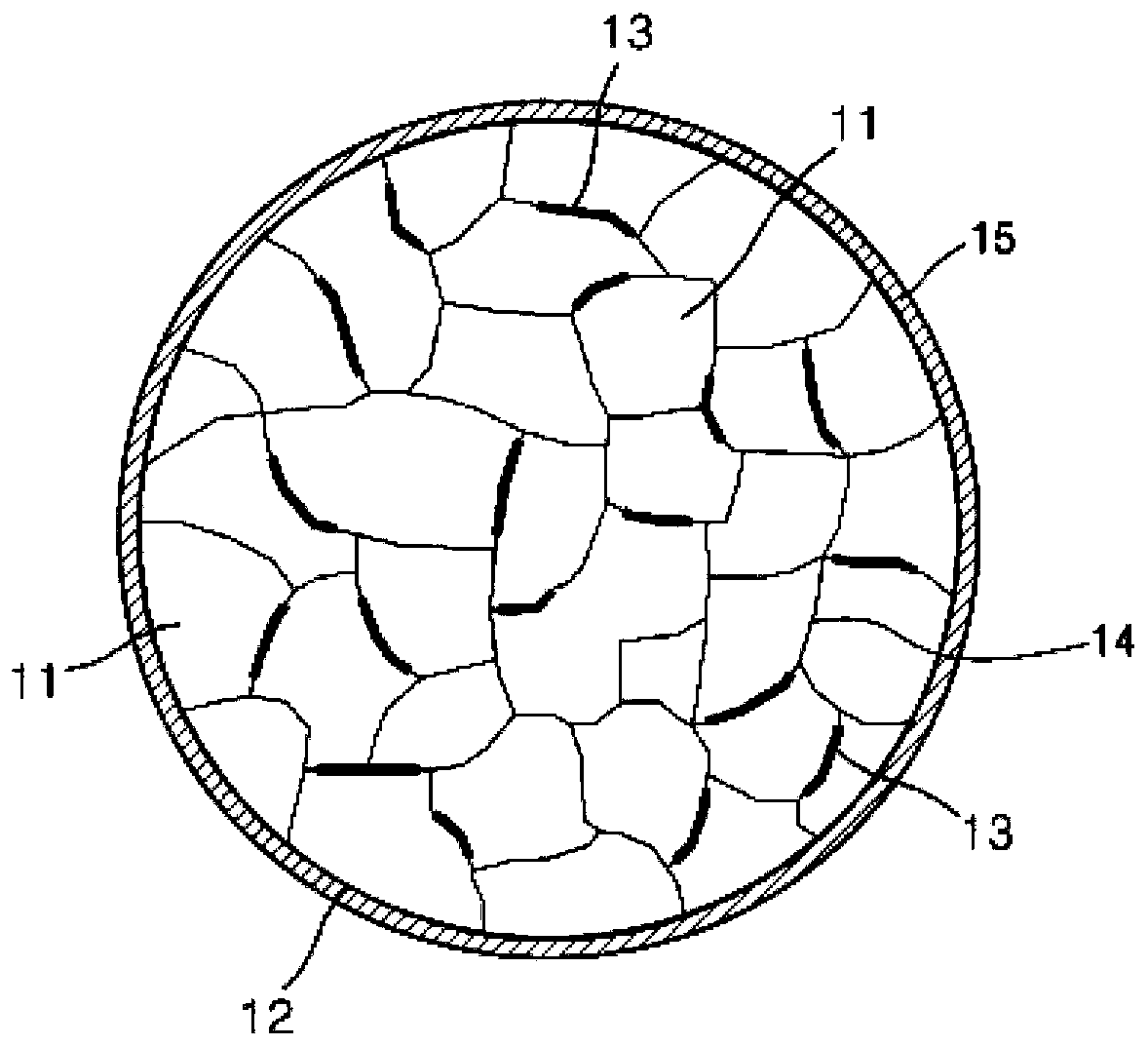

[0180] Through the first heat treatment process, Li 1.09375 (Ni 0.88 co 0.08 mn 0.04 )Al 0.00125 Zr 0.0025 o 2 , which is a lithium nickel transition metal oxide with a layer...

Embodiment 2

[0187] Embodiment 2: Preparation of composite positive electrode active material

[0188] Composite cathode active material was prepared in the same manner as in Example 1, except that the Co(NO 3 ) 2 ·6H 2 O and Mg(NO 3 ) 2 ·6H 2 The amount of the precursor of O is such that the total amount of Co and Mg in the coating film formed on the secondary particle of the composite positive electrode active material is 0.75 parts by weight, with respect to 100 parts by weight of the lithium nickel transition with layered crystal structure Metal oxide.

[0189] The total amount of Co and Mg in the coating film was 0.75 parts by weight with respect to 100 parts by weight of the lithium nickel transition metal oxide having a layered crystal structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com