Production method of calcium sulphate dehydrate and production device thereof

A technology of calcium sulfate dihydrate and production method, applied in the direction of calcium/strontium/barium sulfate, neutralization water/sewage treatment, etc., can solve the problem of affecting the effective recycling and reuse of renewable resources, difficult to solve environmental pollution, low value of by-products, etc. problems, to achieve the effect of reducing drying costs, improving transportation efficiency, and promoting recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Production method embodiment:

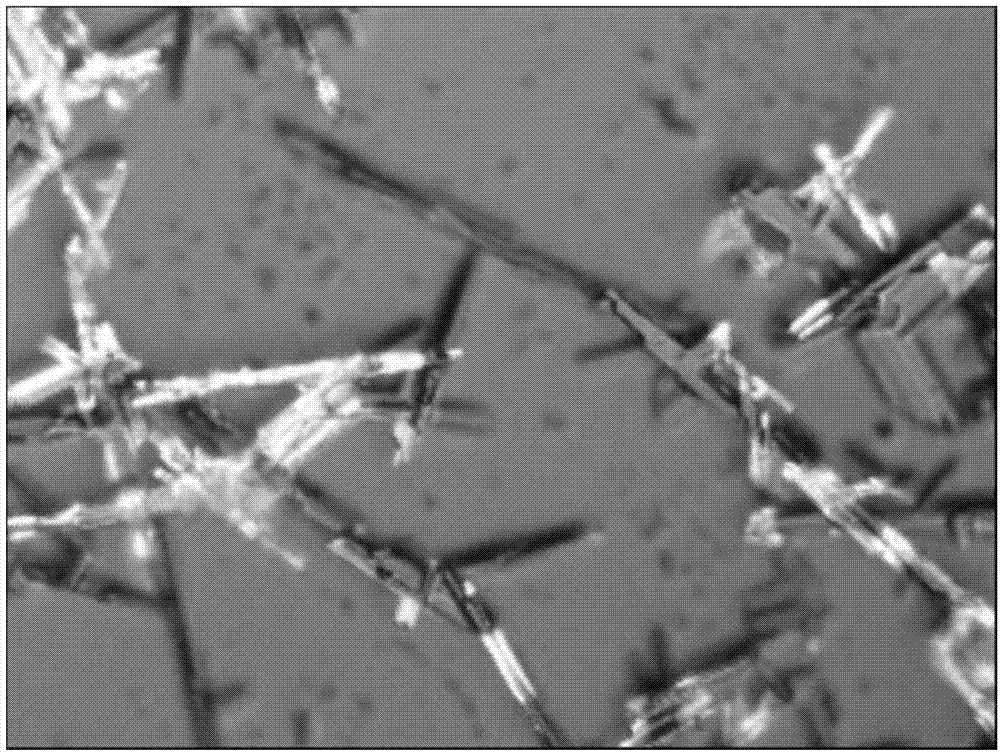

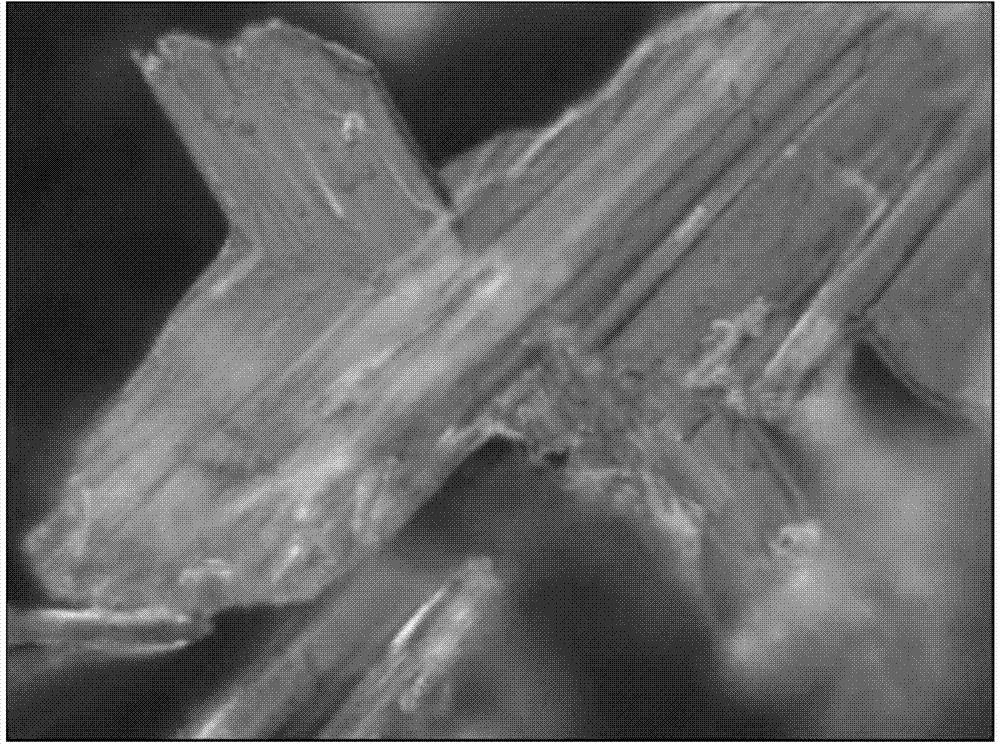

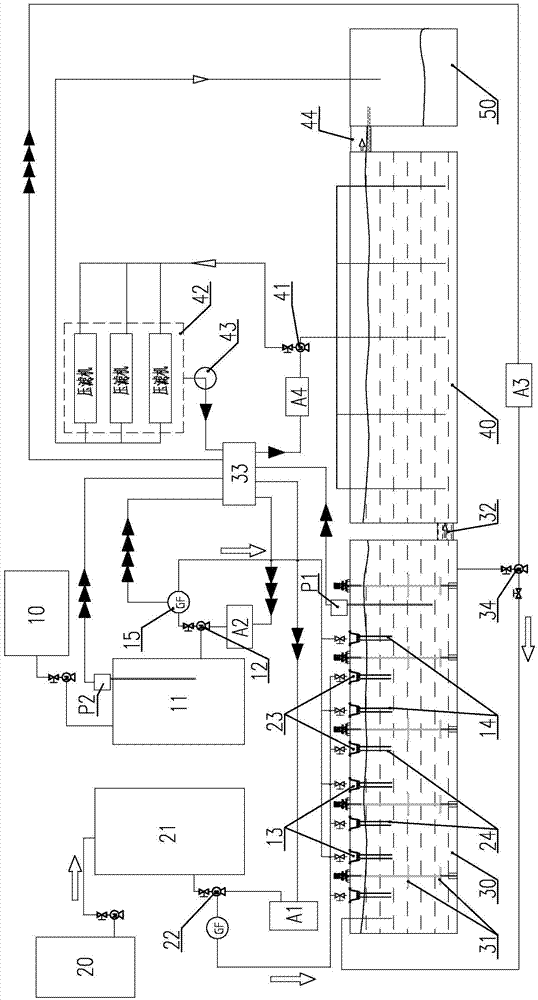

[0034] Such as figure 2 , shown is the crystal photograph of calcium sulfate dihydrate produced by the production method and device of the present invention under a microscope. The production method embodiment of calcium sulfate dihydrate of the present invention, it mixes the acid solution containing waste sulfuric acid and the lye solution containing calcium hydroxide, generates calcium sulfate dihydrate through neutralization reaction, and the acid solution and lye solution are all added Neutralization pool, maintain low shear force and slow and uniform stirring, carry out neutralization and crystallization under the full stirring of the propeller, control the concentration of sulfuric acid in the added acid solution and the concentration of calcium hydroxide in the added lye to 0.15- 0.3mol / L range, meanwhile, control the pH value of the mixed liquid in the neutralization tank to be neutral, and control the retention time of the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com