A preparing method of a polyolefin microporous separating membrane

A microporous membrane, polyolefin technology, applied in flat products, applications, electrical components, etc., can solve the problem of low lateral mechanical strength of polyolefin microporous membranes, large differences in lateral and longitudinal thermal shrinkage, and easy sliding of the lamellar cluster skeleton. and other problems, to achieve the effect of small longitudinal thermal shrinkage, reducing the difference between transverse and longitudinal thermal shrinkage, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

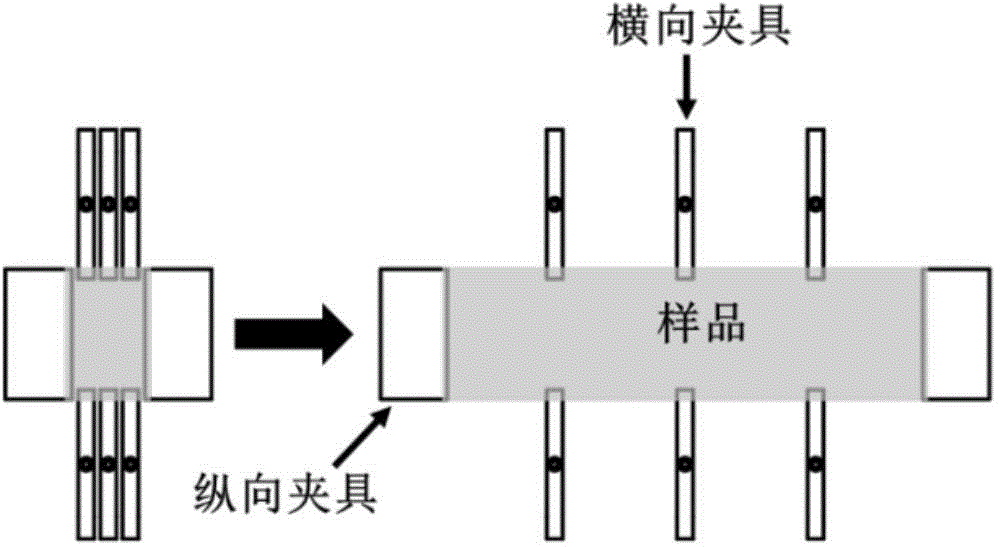

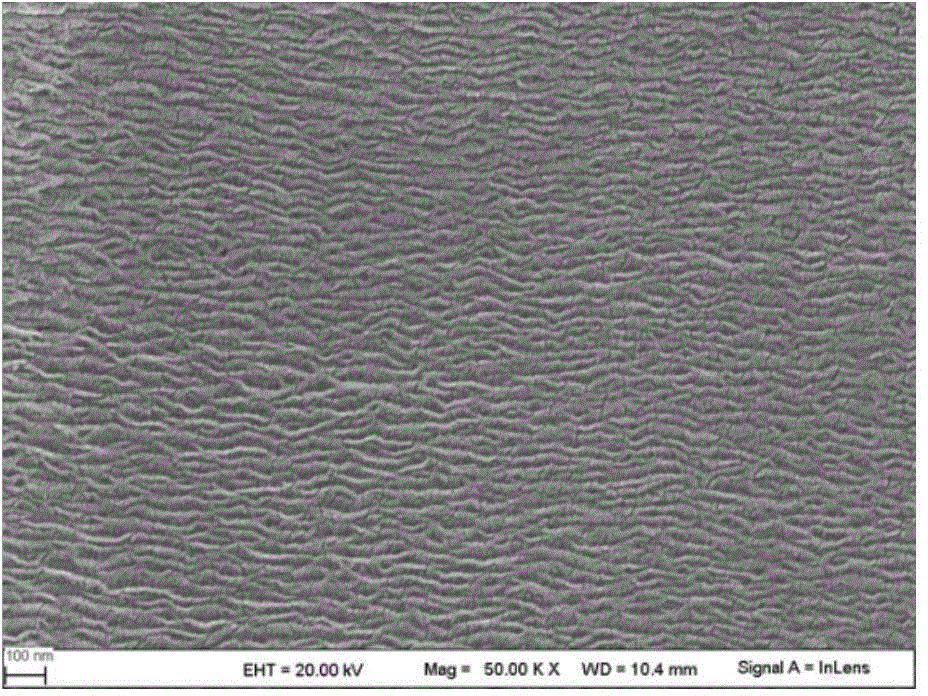

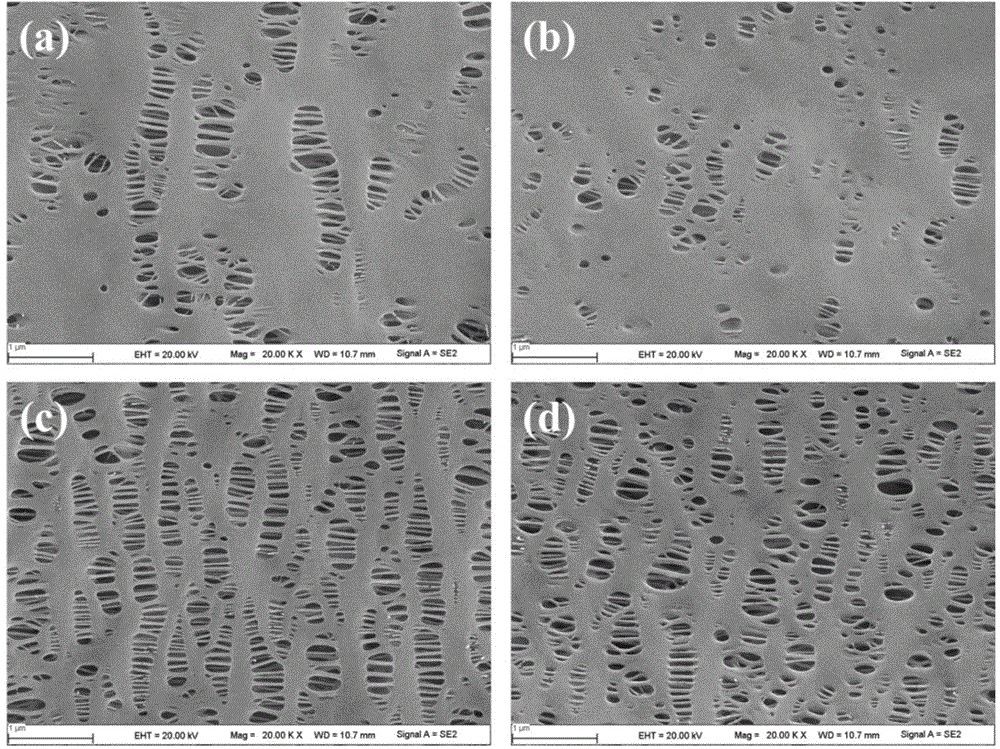

[0034] Select iPP with a melt flow index of 2g / 10min as the raw material, and set the temperature of each section of the single-screw extruder from the hopper to the die to 160°C, 190°C, 215°C, 235°C, 215°C, 215°C, Extrude the iPP melt sheet from the slit die at a screw extrusion rate of 140mm / min at 205°C, adjust the air volume of the air knife, blow cold air to cool the surface of the melt sheet at the die, and cool the melt at 90°C The casting roll is used for traction, the 80°C cooling roll is used for cooling, the distance between the die and the first casting roll is 21mm, the stretching ratio of the casting roll is 42, and it is wound by the winding roll to obtain a row-arranged lamellar structure iPP prefabricated membrane. The prefabricated film was annealed in an oven at 130° C. for 120 minutes to obtain an iPP hard elastomer prefabricated film. After the annealed prefabricated film is stretched 30% at room temperature with a stretching rate of 0.2mm / s by a stretchi...

Embodiment 2

[0037] Select iPP with a melt flow index of 2g / 10min as the raw material, and set the temperature of each section of the single-screw extruder from the hopper to the die to 160°C, 190°C, 215°C, 235°C, 215°C, 215°C, Extrude the iPP melt sheet from the slit die at a screw extrusion rate of 140mm / min at 205°C, adjust the air volume of the air knife, blow cold air to cool the surface of the melt sheet at the die, and cool the melt at 90°C Casting roll for traction, 100°C cooling roll for cooling, the distance between the die and the first casting roll is 15mm, the stretching ratio of the casting roll is 84, and it is wound by the winding roll to obtain a row-arranged lamellar structure iPP prefabricated membrane. The prefabricated film was annealed in an oven at 130° C. for 120 minutes to obtain an iPP hard elastomer prefabricated film. After the annealed prefabricated film is stretched 30% at room temperature with a stretching rate of 0.2mm / s by a stretching device, it is furthe...

Embodiment 3

[0040] Select high-density polyethylene (HDPE) with a melt flow index of 0.07g / 10min as the raw material, and set the temperature of each section of the single-screw extruder from the hopper to the die to 150°C, 195°C, 220°C, and 230°C , 220°C, 230°C, 210°C, extrude the HDPE melt sheet from the slit die at a screw extrusion rate of 140rpm, adjust the air volume of the air knife, blow cold air to the die to cool the surface of the melt sheet, and the cooled The melt is pulled by a casting roll at 110°C, the distance between the die and the first casting roll is 15mm, the stretching ratio of the casting roll is 170, and the HDPE with a row-arranged lamellar structure is obtained by winding up the winding roll Prefabricated film. The prefabricated film was annealed in an oven at 120° C. for 120 min to obtain a HDPE hard elastomer prefabricated film. After the annealed prefabricated film is stretched 30% at room temperature with a stretching rate of 1mm / s, it is raised to 120°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com