Method for in-situ growth of two-dimensional lamellar structured nano-zinc oxide on ceramic tube

A nano-zinc oxide, sheet-like structure technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, measuring devices, etc., to achieve the effect of short time consumption, uniform size, and improved gas sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

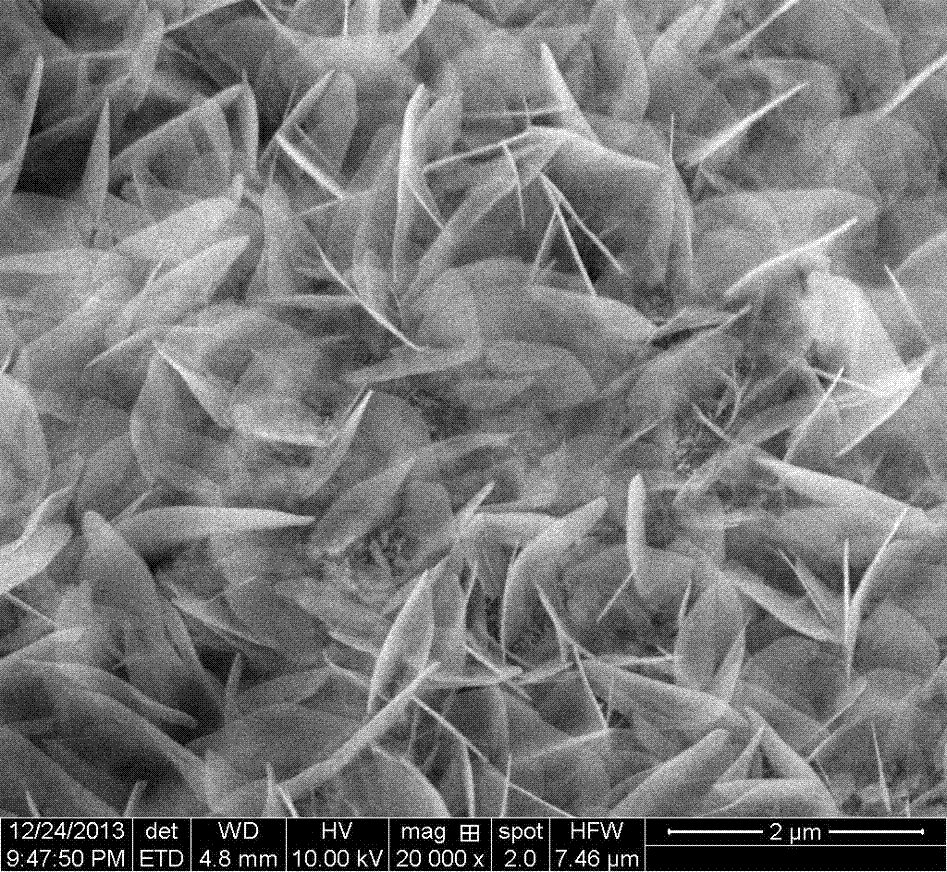

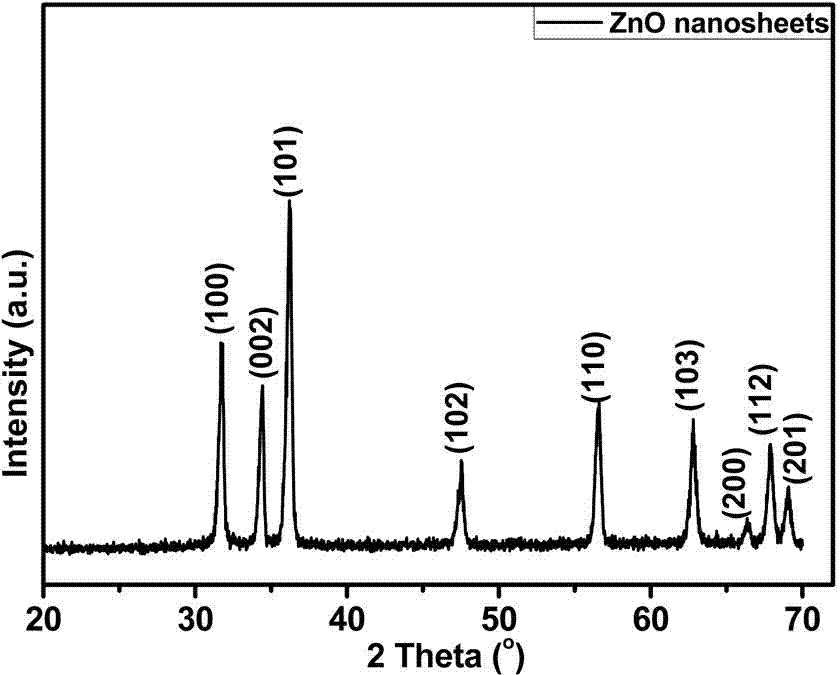

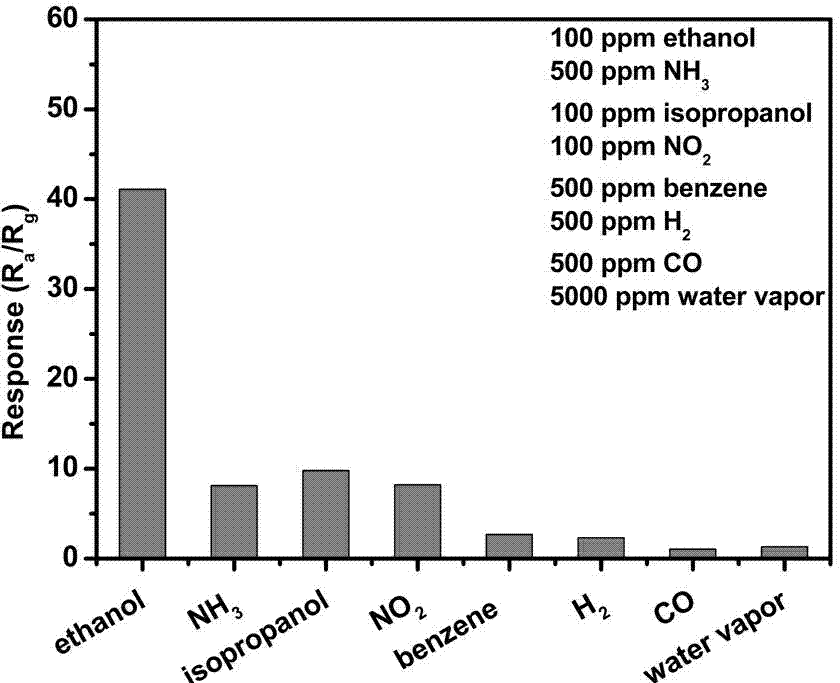

Embodiment 1

[0042]The pre-purchased alumina ceramic tubes were cleaned by ultrasonication with acetone for 20 min, and dried for later use. Add 4.4g of zinc acetate dihydrate to 25 ml of ethylene glycol methyl ether; during the dissolving process of zinc acetate dihydrate, add 1.2g of ethanolamine dropwise to the above solution; when zinc acetate dihydrate and ethanolamine are completely dissolved, Zinc oxide seed layer solution was obtained; stand for 12 hours for later use. Take zinc nitrate and hexamethylenetetramine at a molar ratio of 1:1, add water to prepare a growth solution of 0.025 mol / l, place it in a polytetrafluoroethylene-lined autoclave with a volume of 50 ml, and set aside . Immerse the cleaned alumina ceramic tube in the zinc oxide seed layer solution for 4-12 hours, then take it out, anneal and calcinate at 350°C for 30 min; at this time, a layer of zinc oxide seed layer is formed on the surface of the alumina ceramic tube. The alumina ceramic tube with the zinc oxide ...

Embodiment 2

[0044] Clean the pre-purchased alumina ceramic tube with acetone for 20 min, and bake

[0045] Dry and set aside. Weigh 2.7 g of zinc acetate and add it to 125 mL of ethanol, and heat it under reflux in a constant temperature water bath at 95 °C. After the zinc acetate is completely dissolved, continue heating for 1 h, and then cool it down to room temperature. Then add 0.74 g of lithium hydroxide and ultrasonically oscillate for 1 h; a uniform zinc oxide seed layer solution is obtained. Take zinc nitrate and hexamethylenetetramine at a molar ratio of 1:1, add water to prepare a growth solution of 0.025 mol / l, place it in a polytetrafluoroethylene-lined autoclave with a volume of 50 ml, and set aside . Immerse the cleaned alumina ceramic tube in the zinc oxide seed layer solution for 4-12 h, then take it out, anneal and calcinate at 350°C for 30 min; at this time, a layer of zinc oxide seed layer is formed on the surface of the alumina ceramic tube. The alumina ceramic tube...

Embodiment 3

[0047] The pre-purchased alumina ceramic tubes were cleaned by ultrasonication with acetone for 20 min, and dried for later use. Add 4.4g of zinc acetate dihydrate to 25 ml of ethylene glycol methyl ether; during the dissolving process of zinc acetate dihydrate, add 1.2g of ethanolamine dropwise to the above solution; when zinc acetate dihydrate and ethanolamine are completely dissolved, Zinc oxide seed layer solution was obtained; stand for 12 hours for later use. Take zinc nitrate and hexamethylenetetramine at a molar ratio of 1:1, add water to prepare a growth solution of 0.025 mol / l, place it in a polytetrafluoroethylene-lined autoclave with a volume of 50 ml, and set aside . Immerse the cleaned alumina ceramic tube in the zinc oxide seed layer solution for 4-12 h, then take it out, anneal and calcinate at 350°C for 30 min; at this time, a layer of zinc oxide seed layer is formed on the surface of the alumina ceramic tube. The alumina ceramic tube with the zinc oxide see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com