Preparation method of flaky potassium hexatitanate

A technology for potassium hexatitanate and potassium magnesium titanate platelets, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of uneven morphology and poor crystallinity, and achieve easy control and improved purity. And the effect of high quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

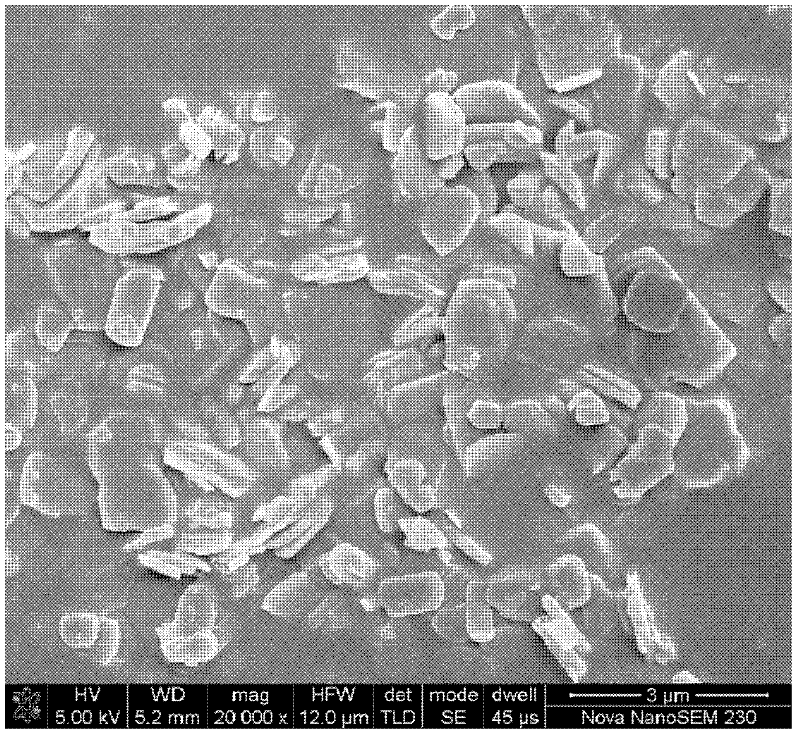

Embodiment 1

[0037] (a) TiO 2 , K 2 CO 3 And Mg(OH) 2 According to the molar ratio K 2 CO 3 : TiO 2 : Mg(OH) 2 =1:3.8:0.8, mix evenly, then add KCl, the mass content is 40%, put the mixture in a ball mill tank, add 200mL alcohol for wet grinding, the ball to material ratio is 1:3, and the ball mill speed is 200r / min , Time 2h, after ball milling and drying, the powder is sintered in a high-temperature furnace to 1050℃, kept for 1h, and then cooled with the furnace.

[0038] (b) The prepared potassium magnesium titanate is crushed, passed through a 20-mesh sieve, washed with boiling water, and filtered with suction. The obtained product was heated to 80°C in a 40% HCl solution and stirred for 3 hours.

[0039] (c) Solid-liquid separation and washing of the acid-treated product. Stir in KOH solution for 12h, adjust pH=12.0.

[0040] (d) Put the above products into the reaction kettle, and hydrothermally react at 200°C for 4 hours.

[0041] (e) After the hydrothermal product is separated by suction...

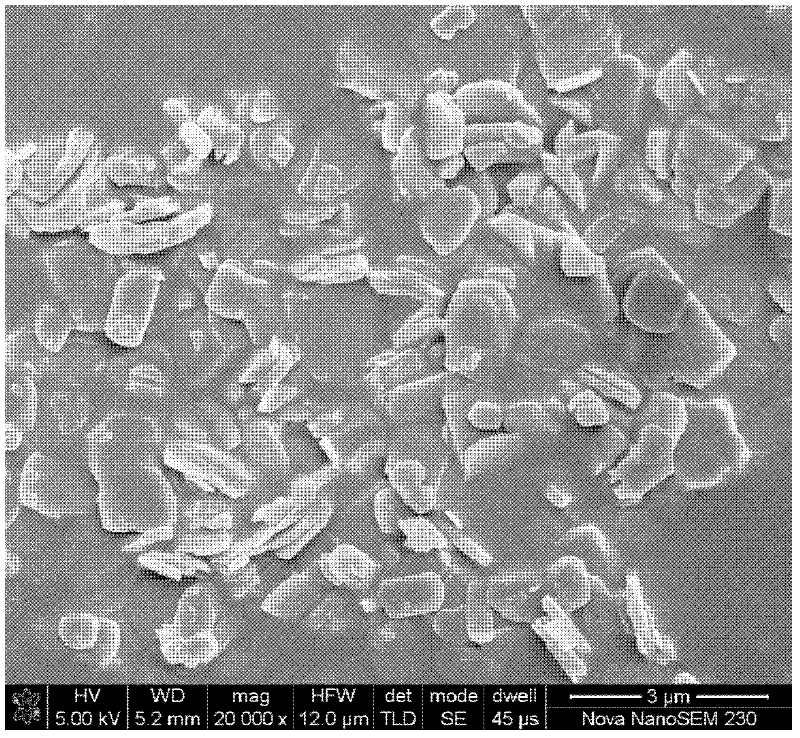

Embodiment 2

[0043] (a) TiO 2 , K 2 CO 3 And Mg(OH) 2 According to the molar ratio K 2 CO 3 : TiO 2 : Mg(OH) 2 =1:3.8:2.0 ratio is evenly mixed, then KCl is added, the mass content is 50%, the mixture is placed in a ball mill tank, 200mL of alcohol is added for wet grinding, the ball-to-material ratio is 1:3, and the ball mill speed is 200r / min , Time 2h, after ball milling and drying, sinter the powder in a high temperature furnace to 1050℃, keep it for 5h, and cool down with the furnace.

[0044] (b) The prepared potassium magnesium titanate is crushed, passed through a 20-mesh sieve, washed with boiling water, and filtered with suction. The obtained product was heated to 80°C in a 50% HCl solution and stirred for 3 hours.

[0045] (c) Solid-liquid separation and washing of the acid-treated product. Stir in KOH solution for 12h, adjust pH=12.0.

[0046] (d) Put the above products into the reaction kettle, and hydrothermally react at 200°C for 6 hours.

[0047] (e) After the hydrothermal produc...

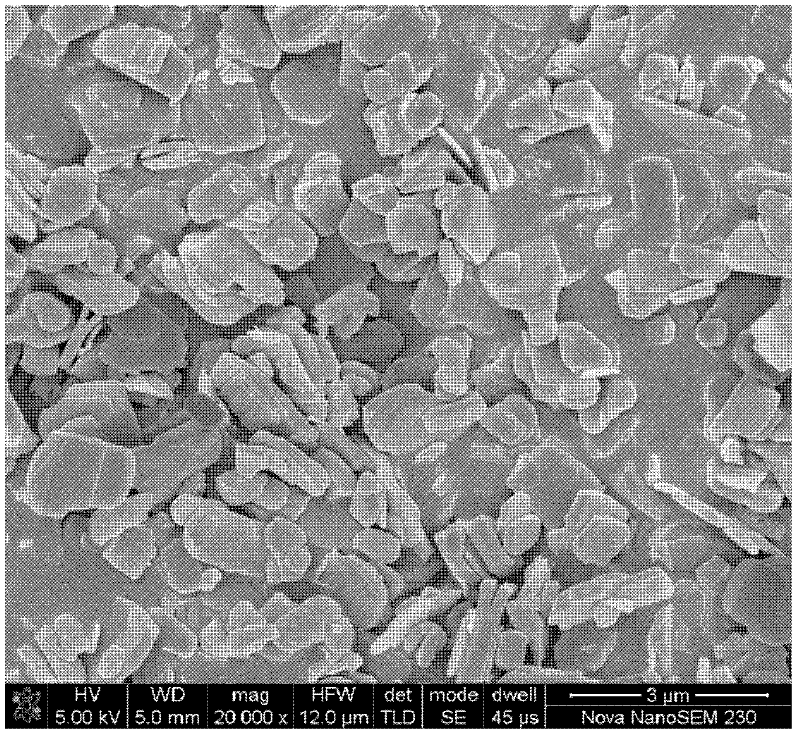

Embodiment 3

[0049] (a) TiO 2 , K 2 CO 3 And Mg(OH) 2 According to the molar ratio K 2 CO 3 : TiO 2 : Mg(OH) 2 =1:4.8:2.0 ratio and evenly mix, then add KCl, the mass content is 60%, put the mixture in a ball mill tank, add 200mL alcohol for wet grinding, the ball to material ratio is 1:3, and the ball mill speed is 200r / min , Time 2h, after ball milling and drying, the powder is sintered in a high-temperature furnace to 900℃, kept for 8h, and cooled with the furnace.

[0050] (b) The prepared potassium magnesium titanate is crushed, passed through a 20-mesh sieve, washed with boiling water, and filtered with suction. The obtained product was heated to 80°C in a 60% HCl solution and stirred for 3 hours.

[0051] (c) Solid-liquid separation and washing of the acid-treated product. Stir in KOH solution for 12h, adjust pH=12.0.

[0052] (d) Put the above-mentioned product into a reaction kettle, and hydrothermally react at 200°C for 8 hours.

[0053] (e) After the hydrothermal product is separated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com