Catalyst for selective hydrodesulfurization and preparation method thereof

A hydrodesulfurization and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of low olefin saturation rate and achieve good desulfurization options sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

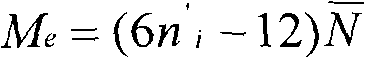

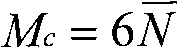

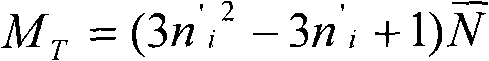

Method used

Image

Examples

Embodiment 1

[0043] Take by weighing 274.2 grams (dry basis) of aluminum oxide hydrate (trade name SB, German Condea company product, wherein gibbsite content 85% by weight) prepared by alkoxy aluminum hydrolysis method, and extrude into a circumscribed circle with a diameter of The 1.4mm trefoil strip was dried at 170°C for 4 hours and calcined at 900°C for 4 hours to obtain carrier Z1.

[0044] Molybdenum and cobalt were introduced into the carrier Z1 by co-impregnation. First, take by weighing 11.2 grams of ammonium paramolybdate, and dissolve it in 90 milliliters of ammonia water with a concentration of 18% by weight until it is clear and transparent, then take by weighing 4.6 grams of basic cobalt carbonate and 15.7 grams of EDTA, and add the above solution to continue dissolving to The total solution is 105 ml. Heating during the dissolution process and keeping the temperature at 50°C, impregnated 100g of carrier Z1 with this solution, and dried at 170°C for 4 hours to obtain cataly...

Embodiment 2

[0046] Weigh 100 g of silica (product of Qingdao Ocean Chemical Special Silica Gel Co., Ltd., specific surface area 387 m2 / g, pore volume 0.99 ml / g), which is called carrier Z2.

[0047] Molybdenum and cobalt are introduced into the carrier Z2 by means of co-impregnation. First, weigh 9.4 grams of ammonium paramolybdate, weigh 7.4 grams of cobalt nitrate, and 7.4 grams of citric acid, and dissolve ammonium paramolybdate, citric acid, and cobalt nitrate in sequence with deionized water to 105 milliliters of the total solution, heat, and keep the dissolution temperature The carrier Z2 was impregnated with this solution at 50°C and dried at 170°C for 4 hours to obtain catalyst C2. The cobalt and molybdenum oxide contents in C2 and the f value of the catalyst are listed in Table 1.

Embodiment 3

[0049] Take by weighing 274.2 grams (dry basis) of aluminum oxide hydrate (trade name SB, German Condea company product, wherein gibbsite content 85% by weight) prepared by alkoxy aluminum hydrolysis method, and extrude into a circumscribed circle with a diameter of The 1.4 mm trefoil strip was dried at 170° C. for 4 hours and calcined at 1000° C. for 4 hours to obtain carrier Z3.

[0050] Molybdenum and cobalt were introduced into carrier Z3 by means of co-impregnation. First, take by weighing 18.0 grams of ammonium paramolybdate, and be dissolved in 90 milliliters of aqueous ammonia with a concentration of 18% by weight until the solution is clear and transparent, then weigh 8.4 grams of basic cobalt carbonate, 22.2 grams of EDTA, add the above solution and continue to dissolve to The total solution is 105 ml. Heated during the dissolution process, and the temperature was kept at 50° C., impregnated 100 g of carrier Z3 with this solution, and dried at 170° C. for 4 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com