A Composite Desulfurization Auxiliary and Its Application

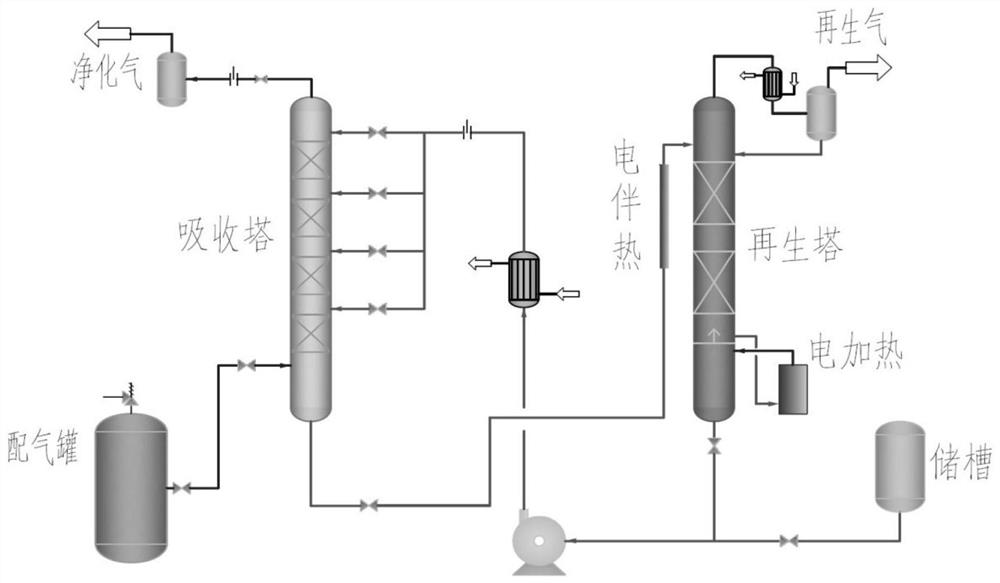

A desulfurization aid and composite technology, which is applied in the field of preparation and application of composite desulfurization aids, can solve the problem of not considering the influence of the analytical performance of the desulfurizer, the inability to reflect the effect of industrial use, and the removal rate of organic sulfur without removal, etc. The problem is to ensure that repeated analysis and regeneration do not degrade, the economic benefits of the device are significant, and the performance of organic sulfur is outstanding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First add 120g of ionized water, 30g of sodium sulfite, and 20g of thiourea into a three-necked flask, raise the temperature to 80±2°C, keep stirring and dissolve, then cool down to 35±5°C, and then add tert-butylaminoethoxy alcohol ether, tert-butylaminopropoxy 150g of alcohol ether and 30g of 1,5-pentanediol, stirred at room temperature and then filtered to remove impurities to obtain compound desulfurization aid WXT-1.

Embodiment 2

[0026] First add 120g of ionized water, 20g of sodium thiosulfate, and 20g of sodium sulfite into a three-necked flask, heat up to 80°C and stir to dissolve, then cool down to 35±5°C, then add 150g of tert-butylaminopropoxy alcohol ether, tert-butylaminobutyl 100g of oxyalcohol ether, 20g of morpholine, and 70g of 1,5-pentanediol were stirred at room temperature and then filtered to remove impurities to obtain the composite desulfurization aid WXT-2.

Embodiment 3

[0028] First, add 100g of ionized water, 20g of sodium thiosulfate, and 10g of sodium sulfite into a three-necked flask, heat up to 80°C and stir to dissolve, then cool down to 35±5°C, and then add 100g of tert-butylaminoethoxy alcohol ether, tert-butylaminobutyl 200g of oxyalcohol ether, 25g of morpholine, and 45g of 1,5-pentanediol were stirred evenly at room temperature, and then filtered to remove impurities to obtain the composite desulfurization aid WXT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com