Quaternary positive electrode material, positive electrode and battery

A positive electrode material and positive electrode technology, applied in the field of batteries, can solve the problem that the quaternary positive electrode material needs to be improved, and achieve the effects of improving intrinsic electronic conductivity, improving structural stability and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

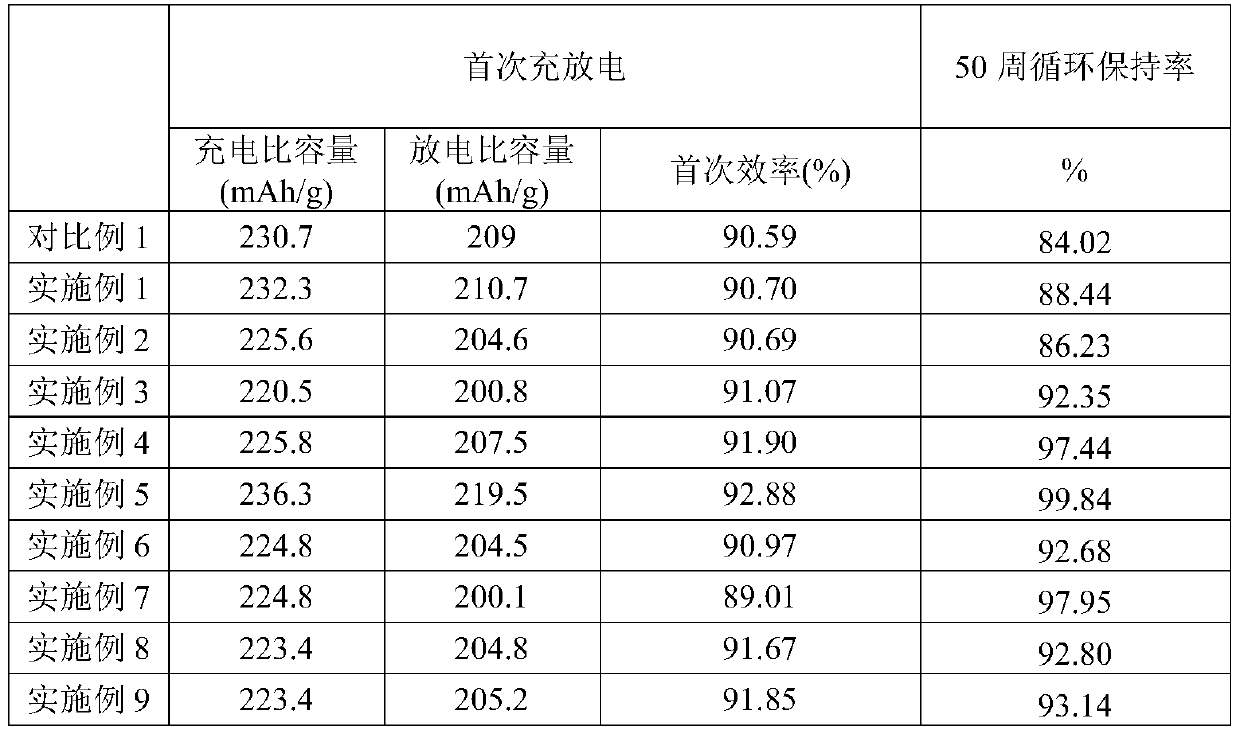

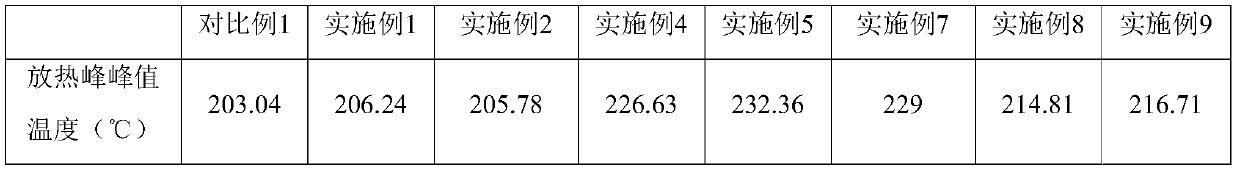

Examples

Embodiment 1

[0035] Embodiment 1, preparation quaternary cathode material A

[0036] (1) The high nickel precursor Ni 0.88 co 0.06 mn 0.03 Al 0.03 (OH) 2 , Li source (LiOH) and Zr source (Zr(OH) 4 ) are mixed to form a mixture; and calcined, cooled, pulverized, and sieved to obtain a Zr-doped quaternary positive electrode material matrix; in the Zr-doped quaternary positive electrode material matrix, the mass fraction of Zr is 3000ppm;

[0037] (2) Al source (Al 2 o 3 ) coating and boron source (H 3 BO 3 ) coating, and after calcination treatment, etc., to obtain the final quaternary cathode material A.

Embodiment 2

[0038] Embodiment 2, preparation quaternary cathode material B

[0039] (1) The high nickel precursor Ni 0.88 co 0.06 mn 0.03 Al 0.03 (OH) 2 , Li source (LiOH) and Al source (Al 2 o 3 ) are mixed to form a mixture; and calcined, cooled, pulverized, and sieved to obtain an Al-doped quaternary positive electrode material matrix; in the Al-doped quaternary positive electrode material matrix, the mass fraction of Al is 3000ppm;

[0040] (2) Al source (Al 2 o 3 ) coating and boron source (H 3 BO 3 ) coating, and after calcination treatment, etc., to obtain the final quaternary cathode material B.

Embodiment 3

[0041] Embodiment 3, preparation quaternary cathode material C

[0042] (1) The high nickel precursor Ni 0.88 co 0.06 mn 0.03 Al 0.03 (OH) 2 , Li source (LiOH), Al source (Al 2 o 3 ) and Zr source (Zr(OH) 4 ) are mixed to form a mixture; and calcined, cooled, pulverized, and sieved to obtain a quaternary positive electrode material matrix co-doped with Al and Zr; in the quaternary positive electrode material matrix co-doped with Al and Zr, the mass of Al The fraction is 3000ppm, and the mass fraction of Zr is 1500ppm;

[0043] (2) Al source (Al 2 o 3 ) coating and boron source (H 3 BO 3 ) coating, and after calcination treatment, etc., to obtain the final quaternary cathode material C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com