Formula and application of xylene solvent for improving solid phase synthesis efficiency of polypeptide

A peptide solid-phase synthesis and xylene technology, which is applied in the preparation methods of peptides, peptides, chemical instruments and methods, etc., can solve the problems of accelerated peptide synthesis, shortened reaction time, less easy purification, etc., to reduce the steric hindrance effect. , the effect of shortening the reaction time and speeding up the synthesis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Solvent formula: dimethylformamide (DMF) / dichloromethane (DCM) / xylene (DMB)=1 / 2 / 0.25

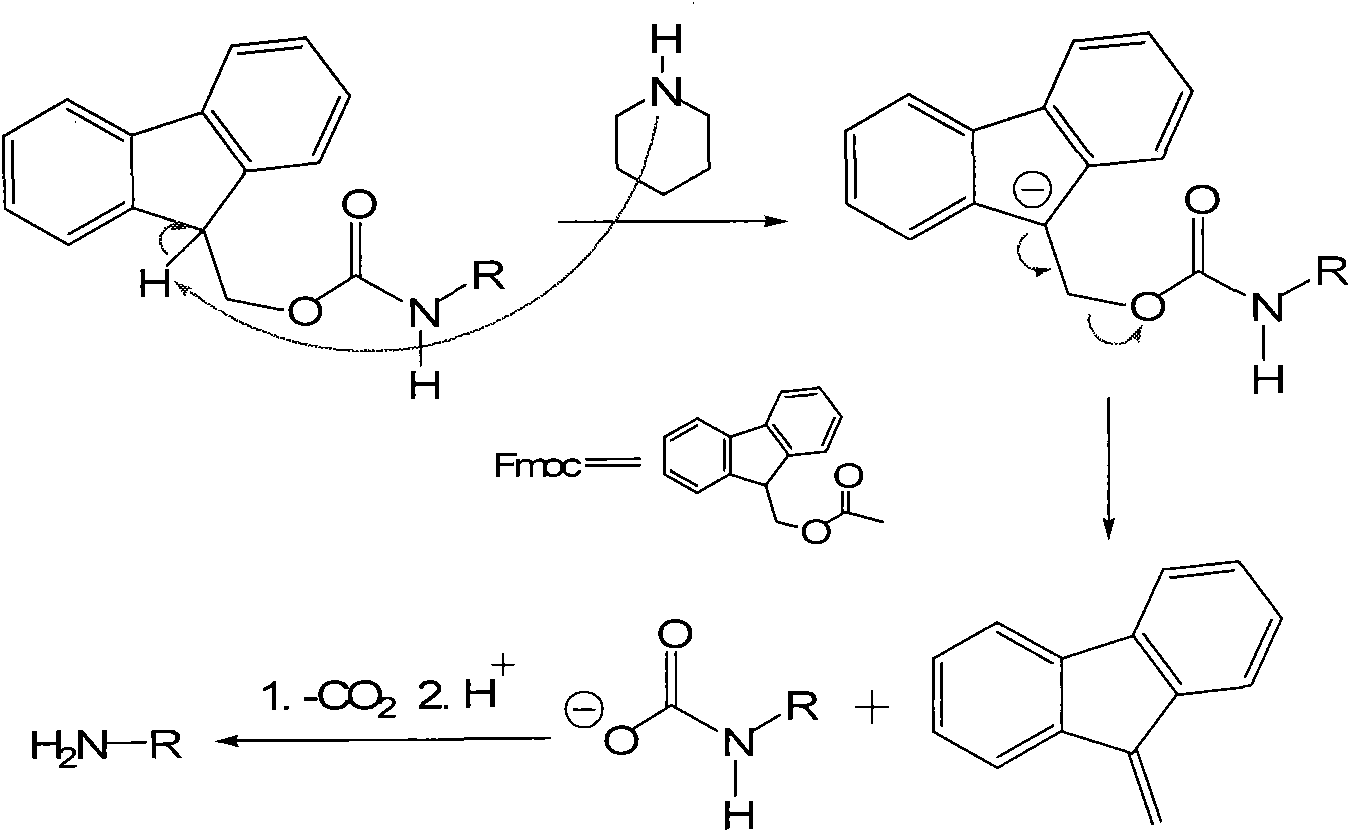

[0019] Such as Figure 1-4 As shown, in the synthesis of the antimicrobial peptide V13K, this formula was used as a solvent for the peptide grafting reaction. After testing, the connection time of the 7th to 16th amino acids of V13K was shortened to 3-4 hours, and the connection time of the 9th histidine was shortened to 3-4 hours. For 8 hours, the yield of pure product was 25-35mg / 0.1mmol resin. Under the same conditions, using traditional common solvents, the 7th to 16th amino acid of V13K was connected for more than 10 hours, and the 9th histidine was connected for more than 20 hours, and the yield of pure product was 7-9mg / 0.1mmol resin .

[0020] The list of raw materials adopted in the embodiment and the foregoing process is as follows:

[0021] no

Raw material and trial product name

source

1

Rink amide MBHA resin

Tianjin Hecheng Technology Co...

Embodiment 2

[0039] The formula of dimethylformamide (DMF) / dichloromethane (DCM) / xylene (DMB) = 1 / 2 / 0.5 was used as the solvent for the peptide grafting reaction. After testing, the connection time of the 7th to 16th amino acids of V13K shorten to 4-5 hours, wherein the 9th histidine connection time is 5 hours.

[0040] Specific steps are as follows:

[0041]The decapping reagent is: hexahydropyridine:DMF=1:4, volume ratio;

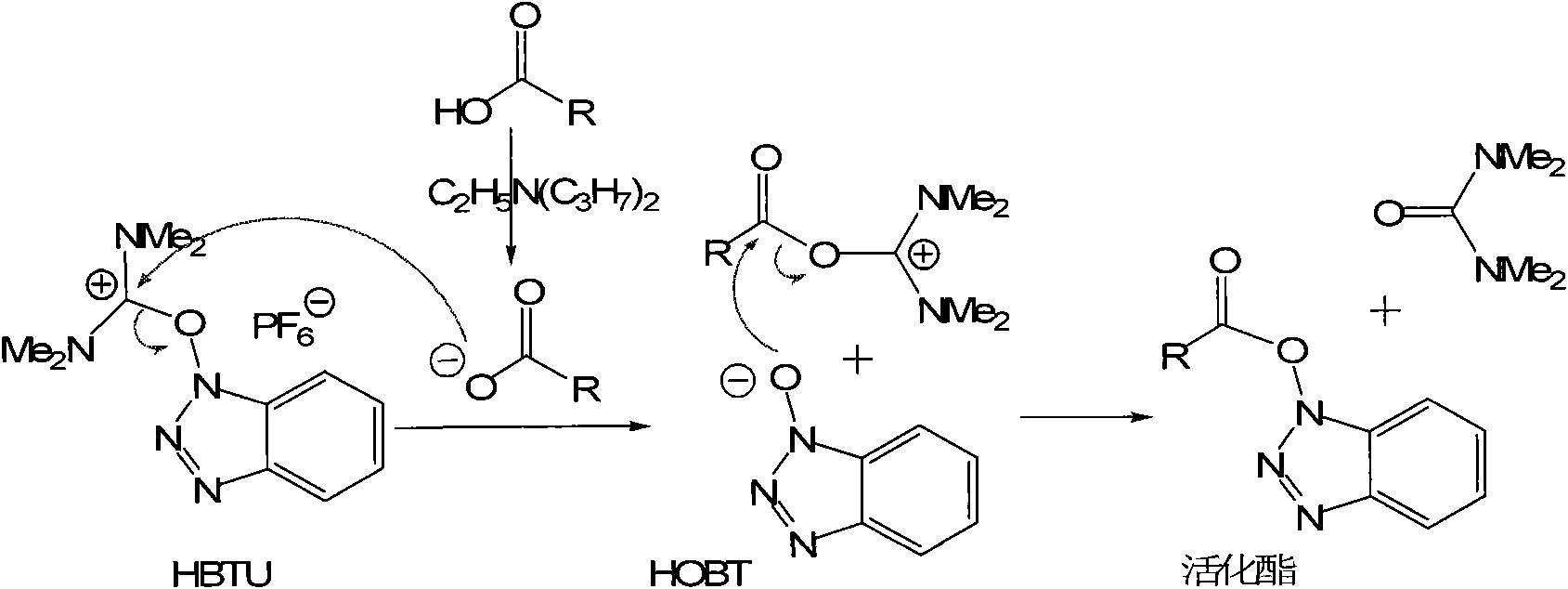

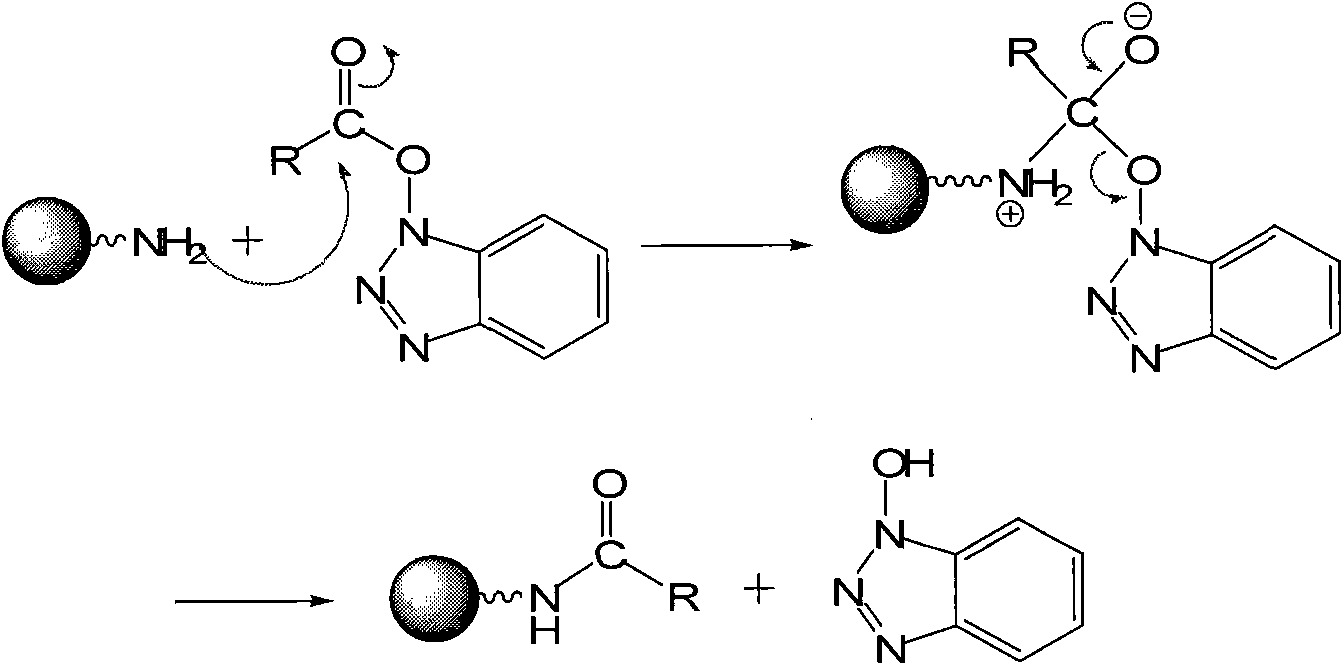

[0042] Said peptide-connecting solvent is: DMF: DCM: DMB=1: 2: 0.5, volume ratio; in the peptide-connecting reagent, the number of moles of HBTU is 4.5 times that of the raw material resin, and the number of moles of HOBt is 3.5 times that of the raw material resin .

[0043] Said ninhydrin detection reagent is: solution A, ninhydrin:ethanol=5:100, mass volume ratio. Solution B, phenol:ethanol=80:20, volume ratio. Solution C, 0.001M potassium cyanide aqueous solution:pyridine=1:49, volume ratio.

[0044] (1) Take 125mg Rink amide MBHA resin (0.8mmol / g resin, 0.1m...

Embodiment 3

[0055] The formula of dimethylformamide (DMF) / dichloromethane (DCM) / xylene (DMB) = 1 / 1.5 / 0.5 was used as the solvent for the peptide grafting reaction. After testing, the connection time of the 7th to 16th amino acids of V13K Reduced to 3-5 hours.

[0056] Specific steps are as follows:

[0057] The decapping reagent is: hexahydropyridine:DMF=1:4, volume ratio;

[0058] Said peptide-connecting solvent is: DMF: DCM: DMB=1: 1.5: 0.5, volume ratio; in the peptide-connecting reagent, the number of moles of HBTU is 4.5 times that of the raw material resin, and the number of moles of HOBt is 3.5 times that of the raw material resin .

[0059] Said ninhydrin detection reagent is: solution A, ninhydrin:ethanol=5:100, mass volume ratio. Solution B, phenol:ethanol=80:20, volume ratio. Solution C, 0.001M potassium cyanide aqueous solution:pyridine=1:49, volume ratio.

[0060] (1) Take 125mg Rink amide MBHA resin (0.8mmol / g resin, 0.1mmol), soak it in 3ml DCM for 8h, make the resin f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com