Epoxy amino chromatography medium and preparation method thereof

A technology of epoxy ammonia and base layer, which is applied in the field of separation and purification, can solve the problems of long preparation cycle and high production cost, and achieve the effects of low cost, short production cycle and short sample retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

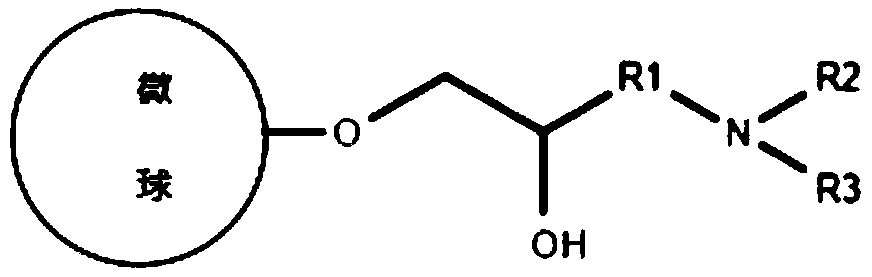

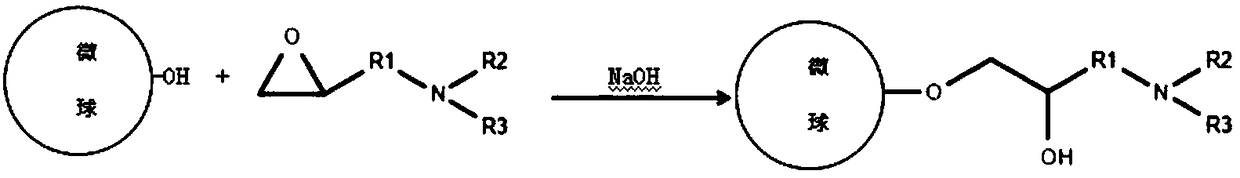

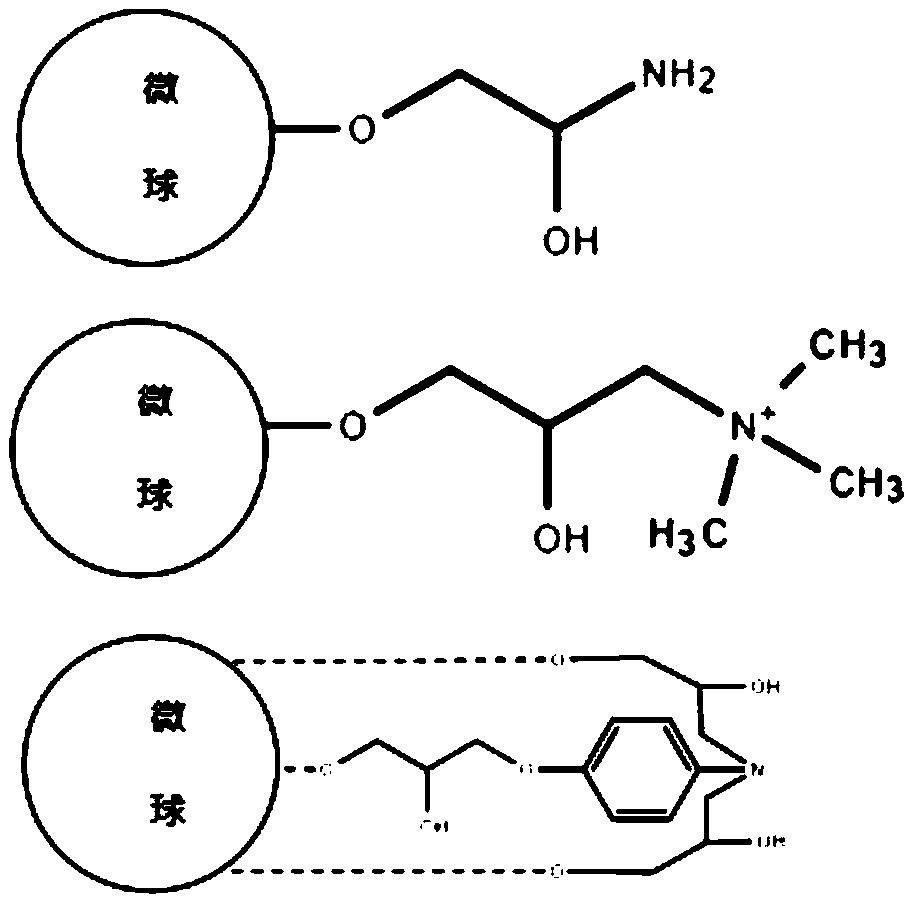

Method used

Image

Examples

Embodiment 1

[0026] Weigh 1000g of Focusose 6BB microspheres into a 5000mL glass reaction bottle, weigh 200g of pure water into the reaction bottle, stir at a constant speed of 500rpm, weigh 200g of glycidyltrimethylammonium chloride into the glass reaction bottle, and then weigh Take 10g of sodium hydroxide and 10g of sodium borohydride into the reaction flask, heat to 50°C, stir vigorously at a constant speed of 500rpm for 18h to obtain the mixture, remove the supernatant to retain the precipitate, and vacuum filter and wash the microspheres with 10 times the volume of pure water, add Store in 20% ethanol preservation solution at room temperature, and take samples to detect ion load and protein load.

Embodiment 2

[0028] Weigh 1000g of Focusose 6BB microspheres into a 5000mL glass reaction bottle, weigh 200g of pure water into the reaction bottle, stir at a constant speed of 500rpm, weigh 400g of glycidyltrimethylammonium chloride into the glass reaction bottle, and then weigh Add 50g of sodium hydroxide and 10g of sodium borohydride into the reaction flask, heat to 50°C, and stir vigorously at a constant speed of 500rpm for 18 hours to obtain the mixture, remove the supernatant to retain the precipitate, and vacuum filter and wash the microspheres with 10 times the volume of pure water, add Store in 20% ethanol preservation solution at room temperature, and take samples to detect ion load and protein load.

Embodiment 3

[0030] Weigh 1000g of Focusose 6BB microspheres into a 5000mL glass reaction bottle, weigh 200g of pure water into the reaction bottle, stir at a constant speed of 500rpm, weigh 600g of glycidyltrimethylammonium chloride into the glass reaction bottle, and then weigh Add 100g of sodium hydroxide and 10g of sodium borohydride into the reaction flask, heat to 50°C, stir vigorously at a constant speed of 500rpm for 18 hours to obtain the mixture, remove the supernatant to retain the precipitate, and vacuum filter and wash the microspheres with 10 times the volume of pure water, add Store in 20% ethanol preservation solution at room temperature, and take samples to detect ion load and protein load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com