Polyamide toughening agent as well as preparation method and use thereof

A technology of toughening agent and polyamide, which is applied in the field of polyamide toughening agent and its preparation, can solve the problems of unreachable and poor mechanical properties of polyamide such as tensile strength and bending strength, and achieve high production efficiency and increased production efficiency. Outstanding toughness effect, good tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

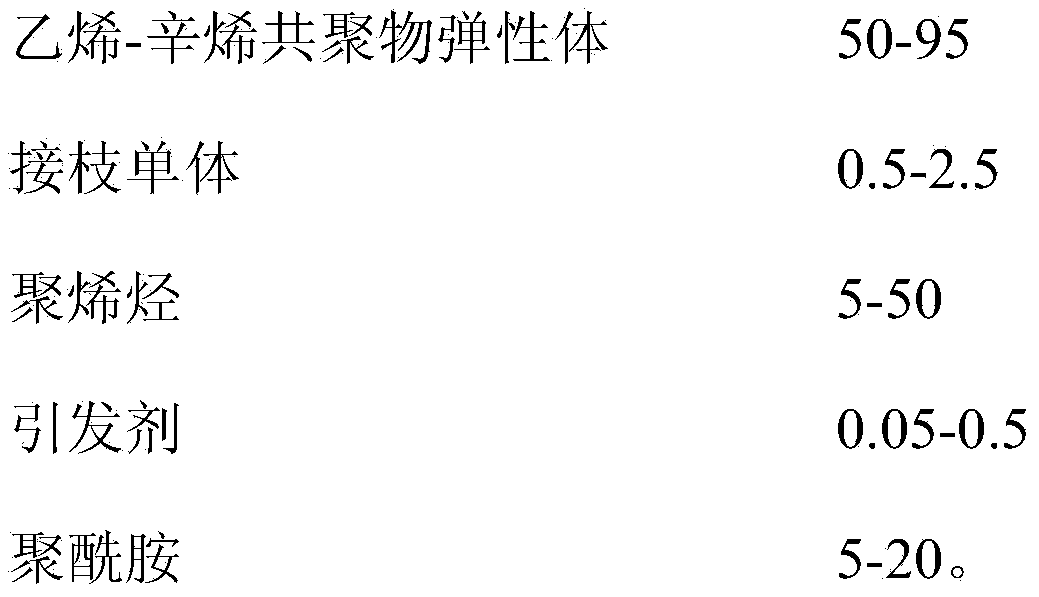

[0037] 1. Proportionally weigh the following components and their parts by weight:

[0038]

[0039] 2. Preparation method:

[0040] (1) Put the MAH, DCP and industrial white oil in the formula amount into the reactor for premixing, control the temperature of the reactor at 40°C, and the stirring rate at 30r / min to obtain the premixed material.

[0041] (2) Put POE, PA, and PP into a small vertical medium-speed mixer, stir at a stirring rate of 70r / min for 3 minutes, then add the premixed material obtained in step (1), and continue stirring for 4 minutes to make it evenly dispersed. A preliminary mixture is obtained.

[0042] (3) Add the preliminary mixture into the twin-screw extruder for extrusion and granulation, control the processing temperature at 170-180°C, the speed of the main machine at 30HZ, the speed of feeding at 15HZ, the current of the main machine at 135-150A, and the speed of the pelletizer 30HZ, the vacuum pressure is greater than 0.4MPa, and the product...

Embodiment 2

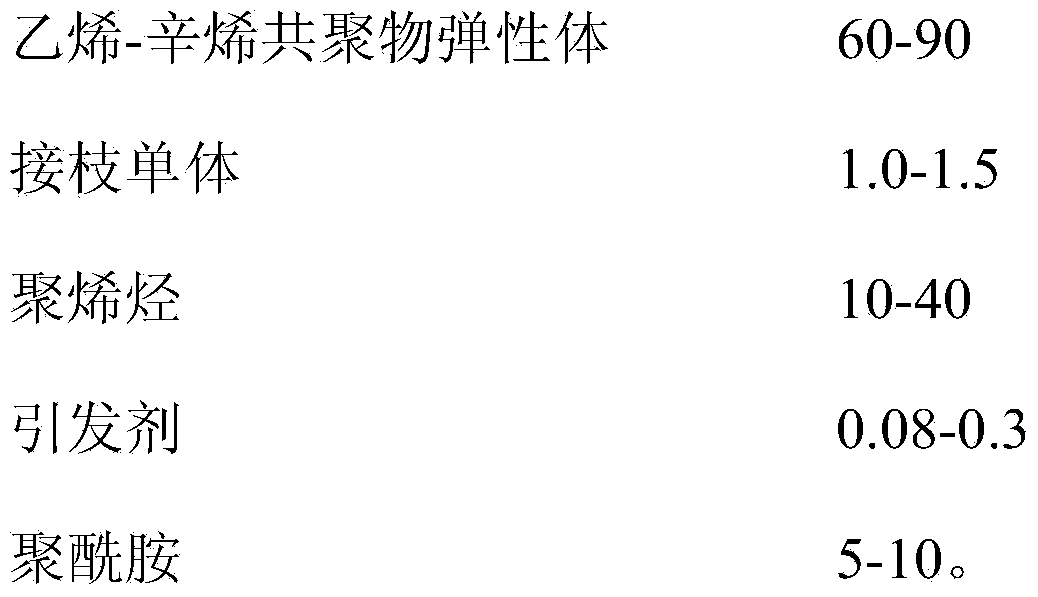

[0046] 1. Proportionally weigh the following components and their parts by weight:

[0047]

[0048] 2. Preparation method:

[0049] (1) Put the MAH, GMA, and industrial white oil in the formula amount into the reactor for premixing, control the temperature of the reactor at 40° C., and the stirring rate at 30 r / min to obtain the premixed material.

[0050](2) Put POE, PA, and PP into a small vertical medium-speed mixer, stir at a stirring rate of 70r / min for 3 minutes, then add the premixed material obtained in step (1), and continue stirring for 4 minutes to make it evenly dispersed. A preliminary mixture is obtained.

[0051] (3) Add the preliminary mixture into the twin-screw extruder for extrusion and granulation, control the processing temperature at 170-180°C, the speed of the main machine at 30HZ, the speed of feeding at 15HZ, the current of the main machine at 135-150A, and the speed of the pelletizer 30HZ, the vacuum pressure is greater than 0.4Mpa, and the prod...

Embodiment 3

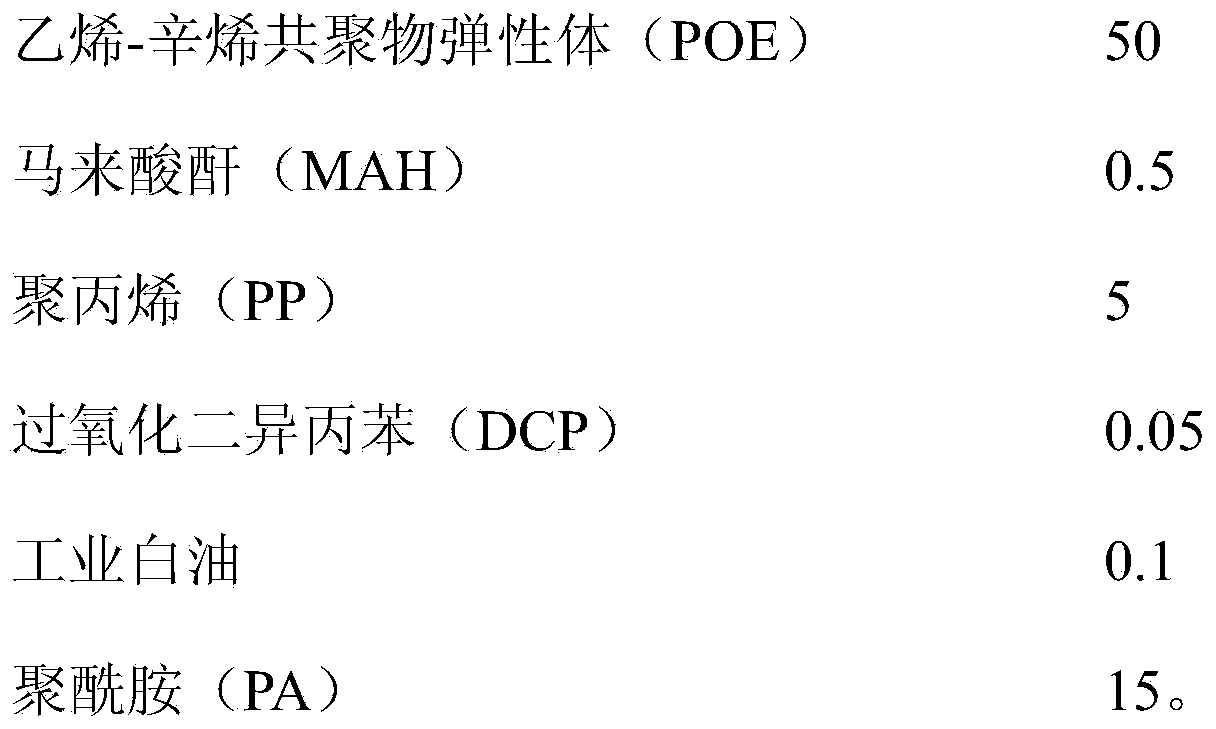

[0055] 1. Proportionally weigh the following components and their parts by weight:

[0056]

[0057] 2. Preparation method:

[0058] (1) Put the formulated amount of MAH, DCP and industrial white oil into the reactor for premixing, control the temperature of the reactor at 50°C, and the stirring rate at 40r / min to obtain the premixed material.

[0059] (2) Put POE, PA, and PP into a small horizontal low-speed mixer, stir at a stirring rate of 25r / min for 5 minutes, then add the premixed material obtained in step (1), and continue stirring for 5 minutes to disperse it evenly, and obtain Preliminary mix of materials.

[0060] (3) Add the preliminary mixed material obtained in step 2 into a twin-screw extruder for extrusion and granulation, control the processing temperature at 170-180°C, the speed of the main machine at 40HZ, the speed of feeding at 20HZ, the current of the main machine at 140-155A, The rotational speed of the granulator is 21HZ, and the vacuum pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com