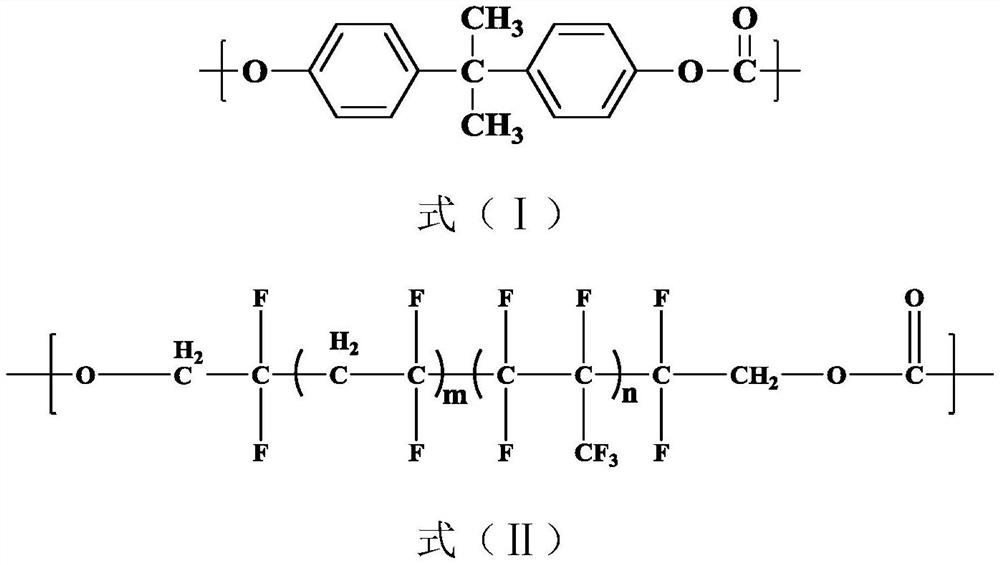

Copolycarbonate and preparation method thereof

A technology of copolycarbonate and comonomer, applied in the field of new copolymer and its preparation, copolycarbonate and its preparation, can solve the problem of poor alloy compatibility, narrowing the application scope of polycarbonate materials, affecting material properties, etc. problems, to achieve the effect of improving the resistance to humidity and heat aging, facilitating the realization of industrialization, and broadening the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

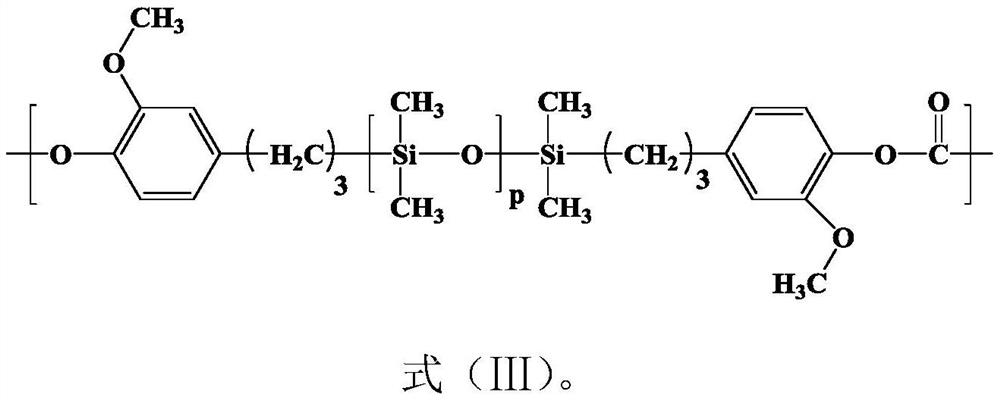

Method used

Image

Examples

preparation example Construction

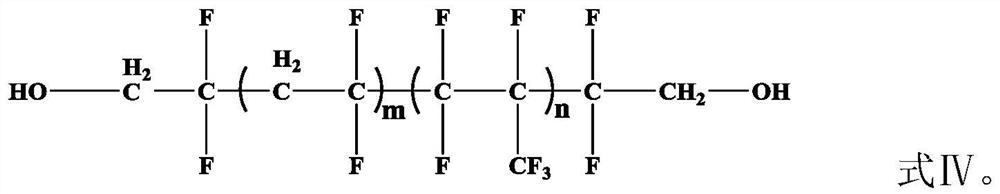

[0053] (1)

[0054] Refer to the synthetic method in the published literature {Wu Meng, Qi Shicheng, Wang Kaiwen, Zhang Liqun, & Yue Dongmei. (2015). Preparation and application of hydroxyl-terminated liquid fluorine 26 rubber. Rubber Science and Technology, 13(012), 10-15.} preparation;

[0055] The structural data of the hydroxyl-terminated liquid Fluoro-26 rubber is listed in Table 1 below,

[0056] Table 1: Structural data of hydroxyl-terminated liquid Fluoro-26 rubber

[0057] Numbering m n F-1 15 48 F-2 95 16 F-3 51 30

[0058] (2)

[0059] Octamethylcyclotetrasiloxane (1420 g, 4.80 mol), tetramethyldisiloxane (40.2 g, 0.3 mol) and clay catalyst Filtrol 20 (23.4 g, 1.6 wt %) were added to a mixer equipped with Thermometer and stirred for 40 minutes to make the material mixture uniform, then the reaction system was heated up to 50°C at a rate of 5°C / min and stirred at this temperature for 3 hours, then the temperature of the reaction s...

Embodiment 1

[0061] Add 342.5g of bisphenol A, 132g of sodium hydroxide, 810g of water, 6.08g of p-tert-butylphenol into a mixer protected by nitrogen, and add 0.48g of catalyst tetrabutylammonium bromide after complete dissolution to form sodium phenolate salt Mutually;

[0062] In another mixer, add 163.2g liquid phosgene and 1631.9g dichloromethane, and mix the two evenly; take another mixer, and prepare 20.3g of hydroxyl-terminated liquid fluorine 26 rubber (numbering F- 1) mix homogeneously with 81g dichloromethane;

[0063] Then put the sodium phenolate salt phase into the polymerization reactor, and then add the prepared phosgene solution and the hydroxyl-terminated liquid fluorine 26 rubber solution into the polymerization reactor at a stirring rate of 550rpm, and add dropwise to the reaction system at the same time The sodium hydroxide aqueous solution with a concentration of 32% by weight keeps the pH value of the reaction system at about 11.4, and maintains the temperature of t...

Embodiment 2

[0066] Add 456.6g of bisphenol A, 200g of sodium hydroxide, 1440g of water, and 5.70g of p-tert-butylphenol into a mixer protected by nitrogen. After completely dissolving, add 2.58g of catalyst tetrabutylammonium bromide to form phenol Sodium brine phase;

[0067] In another mixer, add 237.4g liquid phosgene and 4747.2g dichloromethane, and mix the two evenly; take another mixer, and put the hydroxyl-terminated liquid fluorine 26 rubber (number F- 1) mix homogeneously with 243.0g dichloromethane;

[0068] Then put the sodium phenolate salt phase into the polymerization reactor, and then add the prepared phosgene solution and the hydroxyl-terminated liquid fluorine 26 rubber solution into the polymerization reactor at a stirring rate of 650rpm, and add dropwise to the reaction system at the same time The sodium hydroxide aqueous solution with a concentration of 32% by weight keeps the pH value of the reaction system at about 11.7, and maintains the temperature of the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com