Cold-resistant flame-retardant polycarbonate alloy material and preparation method thereof

A technology of polycarbonate and alloy materials, which is applied in the field of cold-resistant and flame-retardant polycarbonate alloy materials and their preparation, can solve the problem of the failure to significantly improve the low-temperature impact resistance of polycarbonate, the poor impact resistance of flame retardants, and the resistance to It can improve the low temperature impact resistance, improve the flame retardancy, and improve the oxidation resistance and weather resistance.

Inactive Publication Date: 2011-06-15

GUANGDONG ALDEX NEW MATERIAL CO LTD

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the toughening of polycarbonate is mainly achieved by adding additives such as styrene copolymers and polyolefin elastomers. However, the compatibility of styrene copolymers and polyolefin elastomers with polycarbonate is poor, and Its cold resistance is weak, and the low temperature impact resistance of polycarbonate has not been significantly improved.

The existing polycarbonate flame retardants are mainly halogenated flame retardants, phosphorus flame retardants, organosilicon flame retardants and potassium sulfonate flame retardants. Although the above flame retardants can significantly improve the performance of polycarbonate The flame retardant properties of esters, but the addition of toughening agents will significantly reduce the flame retardant properties of the entire system, and the addition of flame retardants will also affect the impact properties of the system, and the low temperature of the above flame retardants The impact resistance is poor, so the low temperature impact resistance of polycarbonate materials is also poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

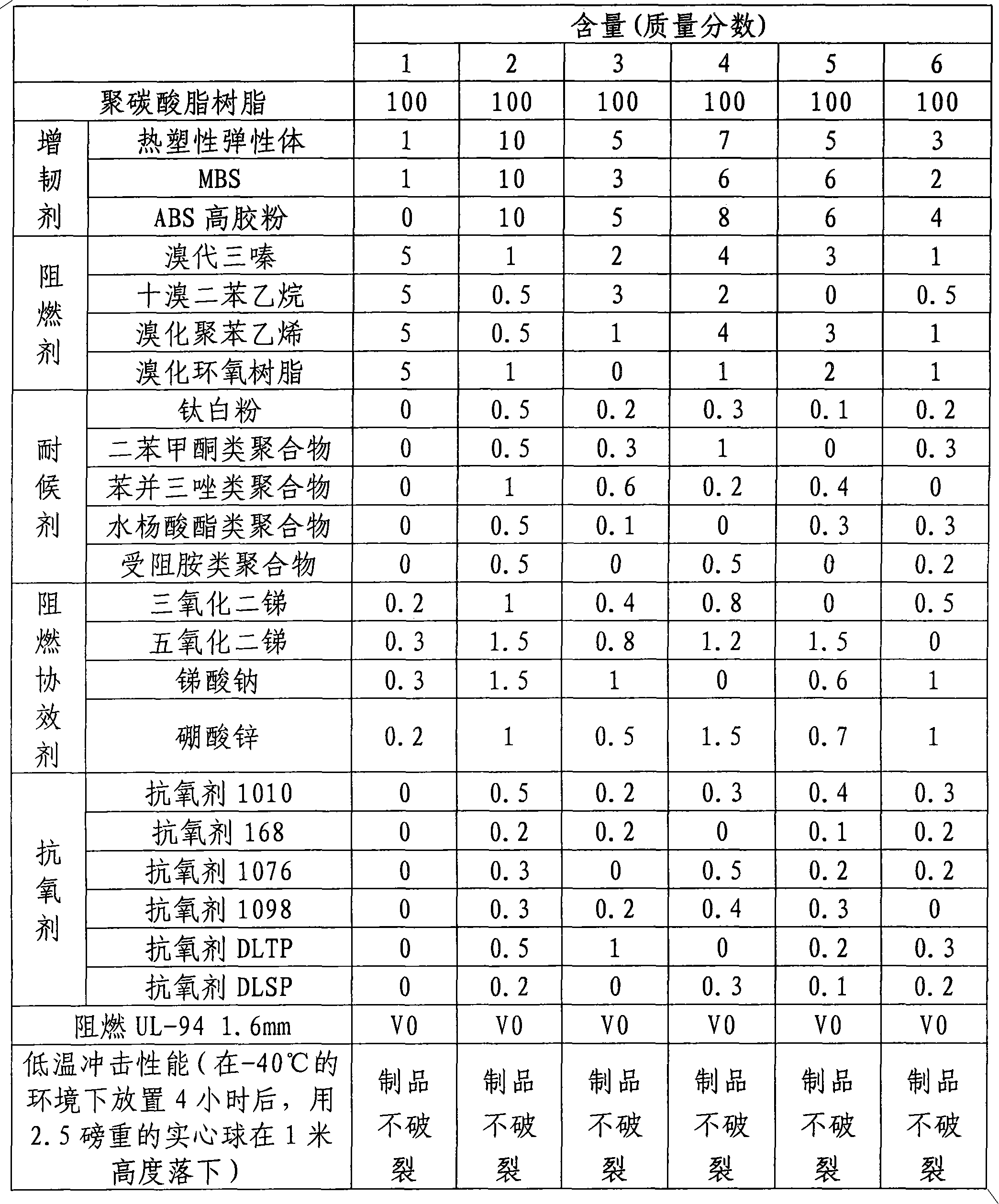

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cold-resistant flame-retardant polycarbonate alloy material. The cold-resistant flame-retardant polycarbonate alloy material is characterized by comprising 100 mass parts of polycarbonate resin, 2 to 30 mass parts of toughening agent, 3 to 20 mass parts of flame retardant, 1 to 5 mass parts of flame-retardant synergist, 0 to 2 mass parts of antioxidant, and 0 to 3 mass parts of weather-resistant agent. The cold-resistant flame-retardant polycarbonate alloy material has high flame-retardant efficiency, good low-temperature impact resistance and good weather resistance.

Description

A kind of cold-resistant flame-retardant polycarbonate alloy material and preparation method thereof technical field The invention relates to the modification and preparation of a polycarbonate alloy material, in particular to a cold-resistant and flame-retardant polycarbonate alloy material and a preparation method thereof. Background technique Polycarbonate is a commonly used engineering plastic with excellent transparency, electrical insulation and impact resistance. Due to its good mechanical properties, it is widely used in transparent products such as lampshades, see-through lenses, and outdoor decorations. However, due to the influence of its molecular chain structure, the rigidity of the polycarbonate molecular chain is strong, and its low temperature toughness is poor. In the low temperature environment, the molecular chain of polycarbonate will become rigid, and its low temperature impact resistance is poor. Therefore, it is necessary to add a toughening agent t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L69/00C08L51/00C08L55/02C08K13/02B29B9/06B29C47/92B29C48/92

CPCB29C48/04B29C48/40B29C48/92B29C2948/92704B29C2948/92895

Inventor 筱璘阮小良桑杰严星桓杨华军李白羽黄恒圳

Owner GUANGDONG ALDEX NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com