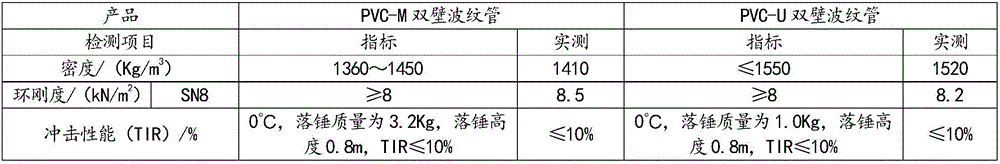

High-impact-resistant-polyvinyl-chloride double-wall corrugated pipe and preparing method thereof

A double-wall corrugated pipe and polyvinyl chloride technology, applied in the field of plastics, can solve the problems affecting the development of PVC-U double-wall corrugated pipe, the damage of PVC-U double-wall corrugated pipe, poor impact resistance at low temperature, etc. The effect of improving impact performance, overcoming lack of toughness, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 A high-impact polyvinyl chloride double-wall corrugated pipe and its preparation method

[0028] A high-impact polyvinyl chloride double-wall corrugated pipe, comprising the following raw materials in parts by weight:

[0029] Polyvinyl chloride resin 100Kg, light calcium carbonate 5Kg, impact additive 10Kg, PE wax 0.2Kg, stearic acid 0.6Kg, processing aid 1.0Kg, processing stabilizer 3.5Kg;

[0030] Among them, the anti-impact additive includes MBS resin and ACM resin with a weight ratio of 1:1.

[0031] The MBS resin is prepared from methacrylic resin, styrene and butadiene through emulsion graft polymerization.

[0032] The ACM resin comprises a copolymer formed by grafting mildly chlorinated HDPE and acrylate with a ratio of parts by weight of 2:1, wherein the content of chlorine in the slightly chlorinated HDPE is 35%.

[0033] The processing aid is ACR type processing aid, its intrinsic viscosity is 4.8-5.1, which is LP-21.

[0034] The processing sta...

Embodiment 2

[0043] Example 2 A high-impact polyvinyl chloride double-wall corrugated pipe

[0044] A high-impact polyvinyl chloride double-wall corrugated pipe, comprising the following raw materials in parts by weight:

[0045] 125Kg of polyvinyl chloride resin, 15Kg of light calcium carbonate, 15Kg of anti-impact additive, 0.5Kg of PE wax, 1.2Kg of stearic acid, 2Kg of processing aid, and 6.25Kg of processing stabilizer;

[0046] Wherein, the anti-impact auxiliary agent includes MBS resin, ACM resin and silicone toughening agent with a weight ratio of 3:2:1, and the silicone toughening agent includes methyl methacrylate, acrylate and silicone. Copolymer of core-shell structure.

[0047] Its preparation method is identical with embodiment 1.

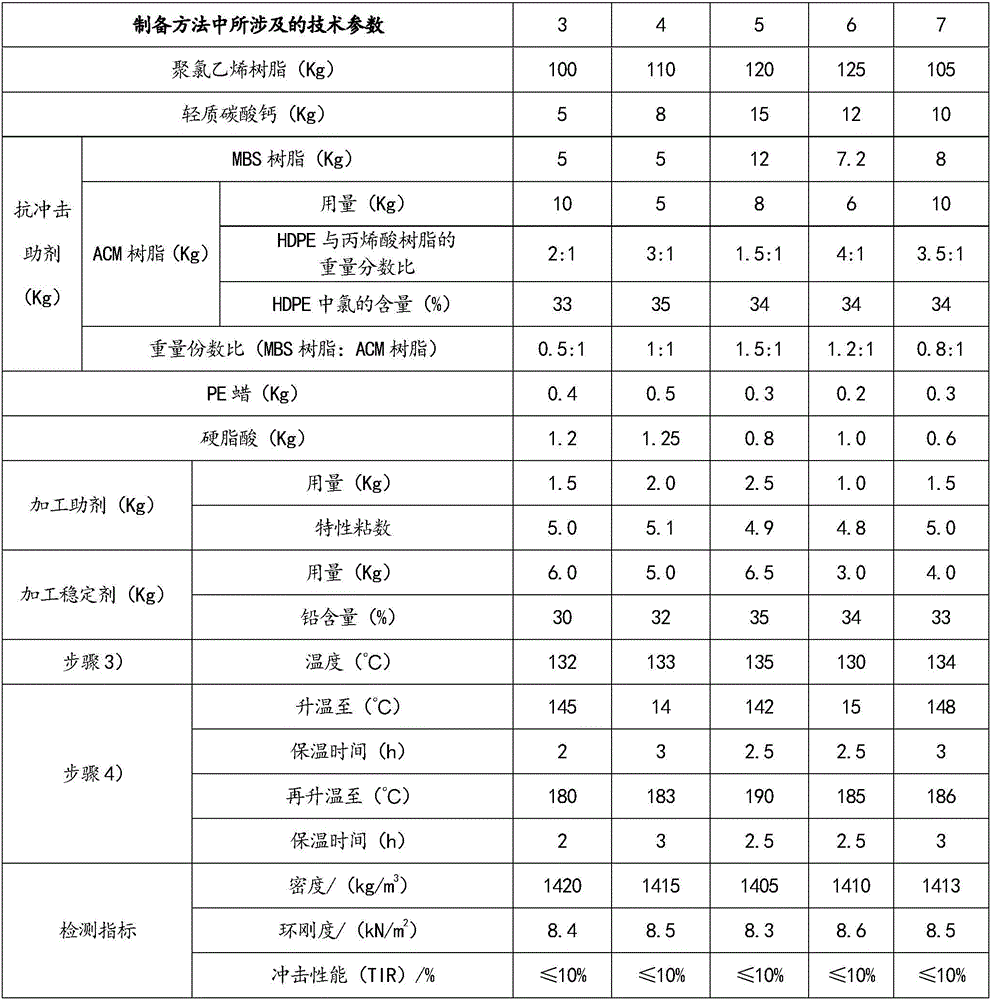

Embodiment 3-7

[0048] Example 3-7 High-impact polyvinyl chloride double-wall corrugated pipe

[0049] Examples 3-7 are a kind of high-impact polyvinyl chloride double-wall bellows respectively, and the types of raw materials and the preparation method are the same as those in Example 1. The only difference is that the amount of raw materials used is different, as shown in the following table Show:

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com